Ulwakhiwo olu-3 lobuNjineli

Ulwakhiwo lobuNjineli beMininzi

Ubunjineli boMgangatho oluncedo

Iinkcukacha

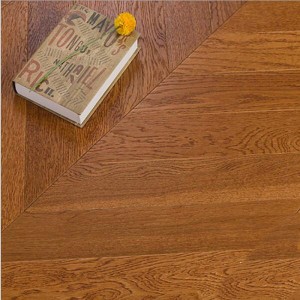

| Uhlobo lomgangatho | Igqityiwe | Iintlobo | Imaple/Imaple enzima |

| Umbala | Ntsundu | Umthunzi | Umthunzi ophakathi / ophakathi |

| Gqibezela Uhlobo | Urethane | Inqanaba leglosi | I-Low-Gloss |

| Isicelo | Eyokuhla | Uhlobo olungundoqo | Ii-Pli ezininzi |

| Inkangeleko yesimo | Ulwimi kunye neGroove | Uhlobo lomda | I-French Bleed |

| Obona Bude Ubuninzi (in.) | 48 | Ubuncinci Ubude (ngaphakathi) | 20 |

| I-avareji yobude (in.) | 33 | Ububanzi (ngaphakathi) | 5 |

| Ukutyeba (ngaphakathi) | 0.55 | Ubushushu obukhazimlayo buhambelanayo | No |

| Ngezantsi kwiBanga | Ewe | Ukuhlohla | Ukudada, Ncamathelisa ezantsi, isikhonkwane ezantsi, Staple Down |

| Isiqinisekiso | ICARB II | Ukutyeba koMaleko (mm) | 3 |

| Umphezulu Gqiba | Unxunguphele, Ukrwelwe ngesandla | Gqiba iWaranti (ngeminyaka) | Iminyaka engama-25 |

| Iwaranti yoLwakhiwo (kwiminyaka) | Iminyaka engama-25 | Ilizwe lemveli | eTshayina |

| Imilinganiselo yokuPakisha (ii-intshi) | Ubude: 4.75 Ubude: 84 Ububanzi: 5 | Imilinganiselo yeMveliso | Ubude: 9/16" Ubude: 15 3/4 - 47 1/4" Ububanzi: 5" |

| Sqft / Ibhokisi | 17.5 | Isindululo 65 | Ingqalelo Abahlali baseCalifornia |

Yintoni inzuzo ngobunjineli bomgangatho womthi?

1. Uzinzo:

Ngenxa yokuba umgangatho womthi owenziwe ngobunjineli usebenzisa i-criss-crossing wood layers, iileya zikhawulelwe omnye komnye, zifana nendlwane yeentaka.Esi sakhiwo sizinzile kwaye sine-deformation encinci.Umthi ngokwawo unama-pores, anokuthi aphinde asuse enye yokwandiswa kunye nokunciphisa.

2. Ukuthuthuzela: Ekubeni umphezulu wenziwa ngomthi oqinileyo wendalo, ukhangeleka kakuhle ngokubonakalayo.Njengemveliso edibana ngokuthe ngqo nolusu, ukuhamba kuyo kufana nokuba ulusu lungqubuzana ngokwemigaqo yokuthintela.Njengemveliso yokhuni, inokulungelelanisa ukushisa kwangaphakathi kunye nomswakama, kwaye ineempawu zokufudumala ebusika kwaye zipholile ehlobo.

3. Ihlala ixesha elide:

Ngepeyinti ye-porcelain powder ye-UV, ukuxhathisa kwe-abrasion ebusweni, ukuxhathisa kwe-abrasion, ukumelana noxinzelelo kunye nokumelana nokukhuhla kunokuthelekiswa nomgangatho we-laminate, kwaye akukho mfuneko yokupeyinta rhoqo ngonyaka.

4. Kulula ukuyifaka:

Yinkqubo yokucofa umgangatho womthi, ngoko akukho mfuneko yokubetha i-keel yomgangatho xa ufaka, ungayifaka ngokwakho.

Indlela yokugcina umgangatho wobunjineli?

1.Ndoyika kakhulu ukutshiswa lilanga.Ukuba ukukhanya kwelanga kunamandla, ndikucebisa ukuba usazoba amakhethini kwaye ungavumeli umgangatho ukuba umelane nokukhanya okunamandla, ngaphandle koko umgangatho uya kuqhekeka.

2. Uninzi loyika ukungqubana nezinto eziqinileyo, ezinjengezithende eziphakamileyo.Kungcono ukhumbule ukutshintsha iziliphu zakho xa ungena egumbini

3. Musa ukusebenzisa i-mop emanzi kakhulu, ngoko kufuneka siyisonge yome, kwaye musa ukusebenzisa isepha okanye amanzi anesepha ukuyicoca xa ugudla umgangatho.

4. Ukwesaba ama-blisters, xa amanzi echithwa phantsi, kufuneka usebenzise ilaphu elithambileyo lekotoni ukuze usule amanzi ngeli xesha, kwaye uvumele ukuba lome ngokwemvelo.Akufunekanga usebenzise isomisi seenwele ukomisa.

5. Ukuze ugcine umgangatho ukhangeleka umtsha, wax rhoqo.Ixesha lokuweksa ngokubanzi limalunga nonyaka omnye.

Uhlobo loyilo

Cofa Uhlobo

Umgangatho wobuNjineli weT&G

Umgangatho wobunjineli we-Unilin

Gqibezela Uhlobo

Umgangatho woBunjineli obuNjineli obuxutyushwe ngesandla

Ngocingo oluKhanyayo-Ibrashi yobunjineli yoMgangatho

Umgangatho woBunjineli oMphezulu oMphezulu

IBanga leVeneer

Umgangatho wobunjineli we-ABCD

Umgangatho wobunjineli weCDE

Umgangatho owenziwe ngobunjineli we-ABC

Umgangatho owenziwe ngobunjineli be-AB

Isatifikethi

Inkqubo yeMveliso

Imarike yethu

Usetyenziso

Iprojekthi 1

Iprojekthi yesi-2

Ufakela njani umgangatho wokhuni owenziwe ngobuNjineli

Ufakela njani umgangatho wokhuni owenziwe ngobuNjineli

INYATHELO 1.

Coca umhlaba, hlakula isamente ephuma emhlabeni, uze usebenzise umtshayelo ukuwucoca.Isanti kunye ne-samente slurry emhlabeni kufuneka ihlambuluke ngokucokisekileyo, ngaphandle koko iya kurhashaza emva kokufakwa!

Amagqabantshintshi:

Umgangatho unokubekwa kuphela xa ubumanzi bomhlaba bungaphantsi kwama-20, ngaphandle koko, umgangatho uya kuba ngumbumba kwaye ube ne-arched emva kokuwubeka!

INYATHELO 2.

Emva kokuba wonke umhlaba uhlanjululwe, usasaze umgca omncinci wefilimu yeplastiki, omele ugutyungelwe ngokupheleleyo, kwaye amajoyina kufuneka adibaniswe ukuze ahlukanise umgangatho kunye nomhlaba.

INYATHELO 3.

Emva kokubeka ifilimu yeplastiki, beka ifilimu ekhethekileyo ye-mulch phantsi.Kufuneka kwakhona ibekwe kwinqanaba kwaye ibekwe ngokuqinileyo.Kungcono ukuba abantu ababini bancedise.

INYATHELO 4.

Emva kokubeka i-mulch, umfakeli wakhupha imigangatho emininzi ebhokisini wawandlala phantsi wonke, ekhetha umahluko wombala, ebeka umehluko omkhulu wombala phantsi kwebhedi kunye nekhabhathi, kwaye wayisasaza kwindawo ecacileyo kunye nombala ofanayo. umahluko.

INYATHELO 5.

Qala ukufakwa ngokusesikweni komgangatho.Umphathi wofakelo usika imigangatho nganye nganye, aze ayifake njengoko kubonisiwe kulo mfanekiso ulandelayo.Sebenzisa nje isando ukuqinisa phakathi komgangatho kunye nomgangatho.Inkosi yokufakela inobuchule kakhulu kwaye isantya sofakelo sikhawuleza kakhulu!Shiya umgama omalunga ne-1 cm phakathi komgangatho kunye nodonga.

INYATHELO 6.

Ukuba umgangatho ude kakhulu, yibeke kwi-cutter yomgangatho kwaye uyinqumle ubude obufunekayo.Umatshini wokusika awukwazi ukufakwa ngokuthe ngqo kwiitayili zomgangatho.Ukuze kuthintelwe ukuba umngxuma ungaphuli, ikhadibhodi engqingqwa kufuneka ibekwe phantsi.

INYATHELO 7.

Ngokuqhelekileyo, ukufakwa komgangatho kuqhutyelwa ngabantu aba-2, isamba esingama-35 square metres, kwaye kuthatha iiyure ezi-6 kuphela.

INYATHELO 8.

Emva kokufakwa komgangatho, faka umthombo phakathi komgangatho kunye nodonga.Intwasahlobo iya kwanda kwaye ivume ubushushu.Sebenzisa isixhobo esikhethekileyo sentsimbi ukusifaka kwisikhewu.

INYATHELO 9.

Ukufakela i-skirting, kufuneka ulungise i-skirting eludongeni ngezikhonkwane, kwaye utywine i-skirting kunye nodonga nge-glass glue.

INYATHELO LE-10.

Umgangatho kunye ne-skirting zifakwe zonke, imibala yazo isahambelana, kwaye umgangatho osanda kufakwa uhle kakhulu, ngoko umgangatho ofakiweyo awunasandi.

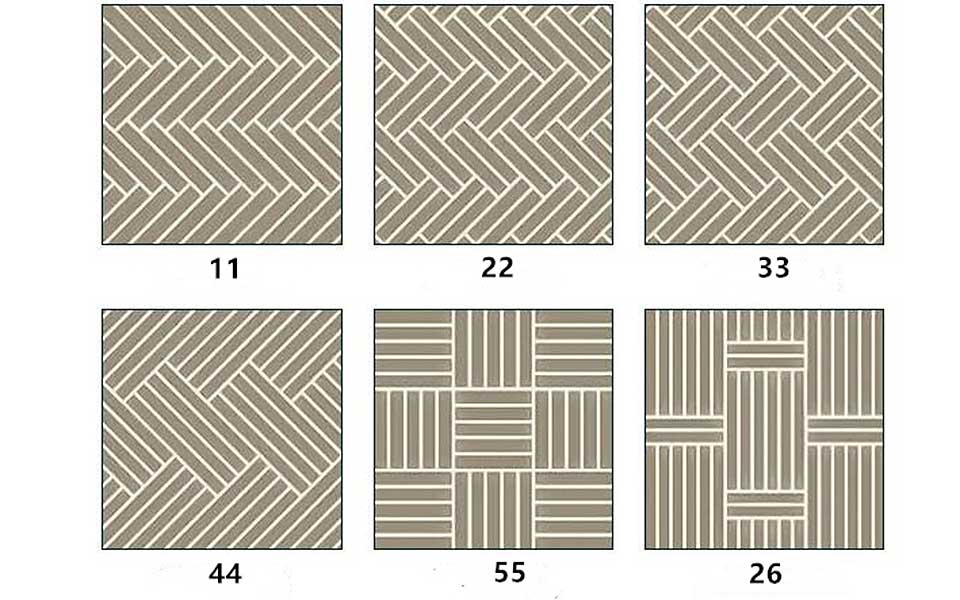

Ubunjineli obuhlukeneyo boMgangatho woMthi, iindlela zoFakelo

Ubunjineli obuhlukeneyo boMgangatho woMthi, iindlela zoFakelo

1.Classic Series ngobunjineli phantsi Flooring

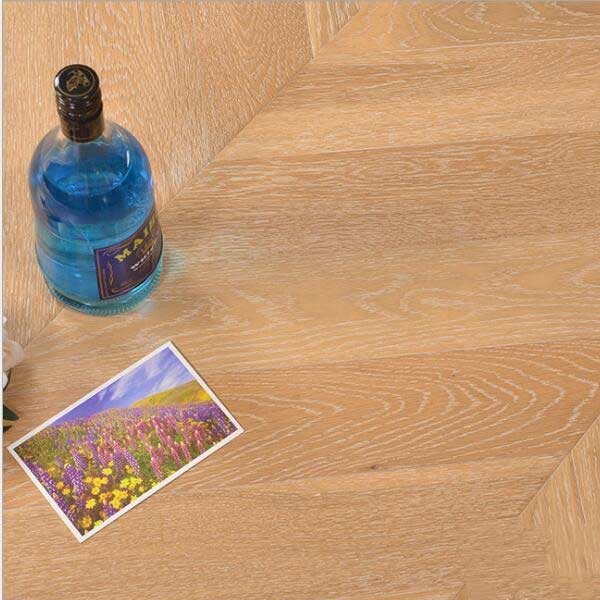

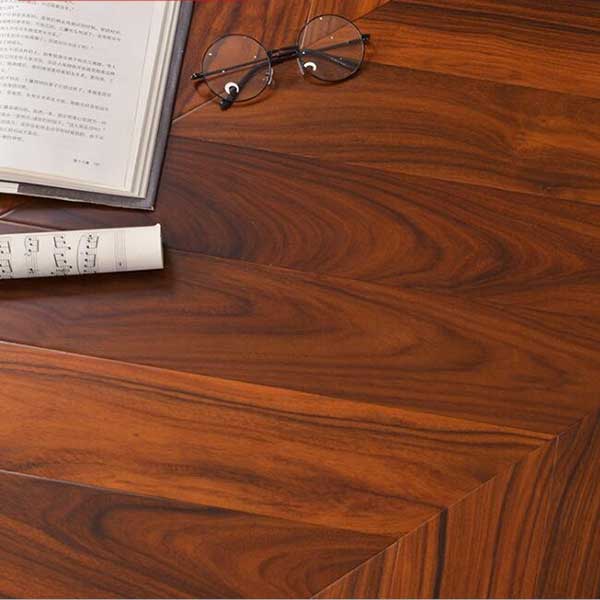

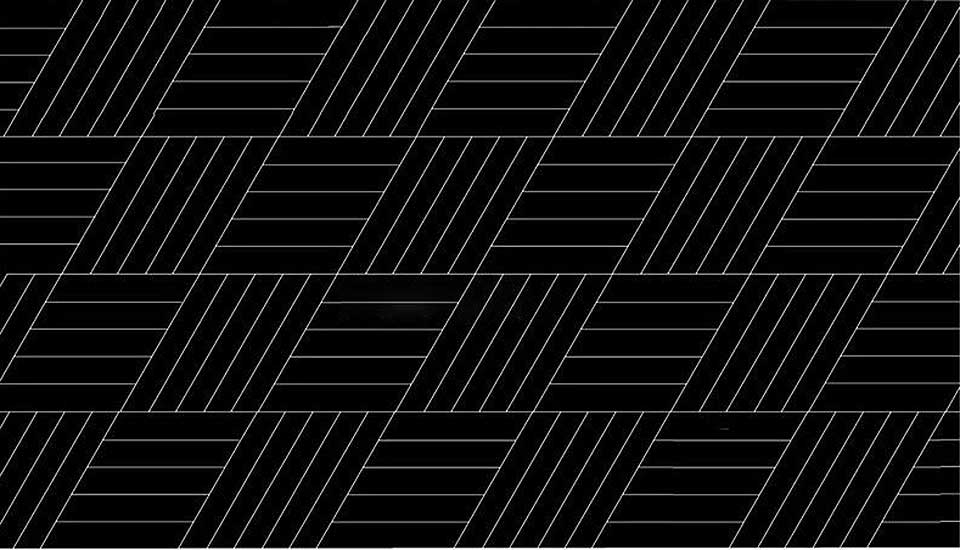

2.Herringbone Series Ubunjineli boMgangatho

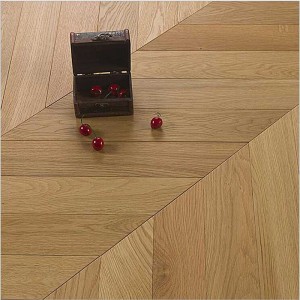

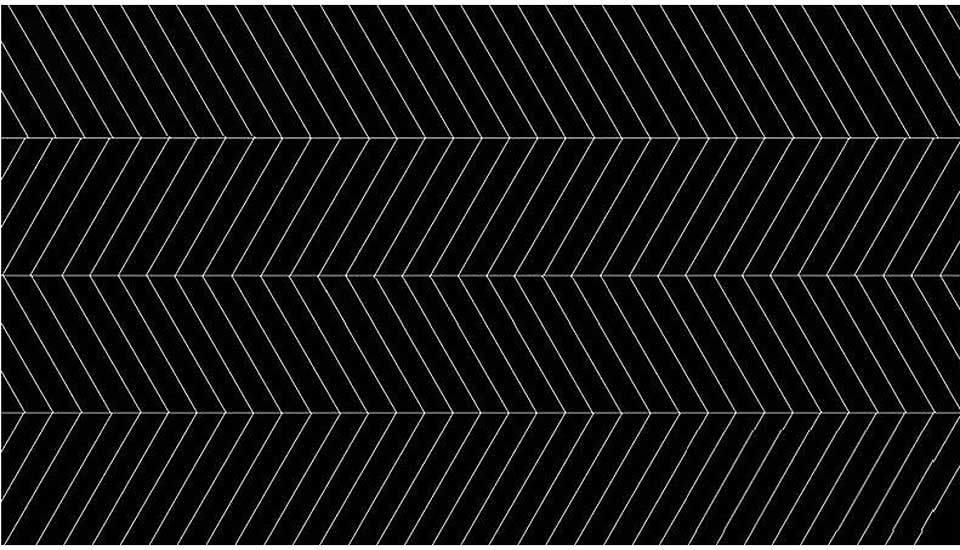

3.Chevron Series Ubunjineli phantsi komgangatho

| Ukhuseleko loMlilo: | Ukusabela kumlilo - umgangatho womthi wenza kwi-EN 13501-1 Dn s1 |

| I-Thermal Conductivity: | I-EN ISO 10456 kunye ne-EN ISO 12664 Iziphumo 0.15 W/(mk) |

| Isiqulatho sokufuma: | EN 13183 – 1 Imfuneko: 6% ukuya 9% avareji Iziphumo: <7% |

| I-Thermal Conductivity: | EN ISO 10456 / EN ISO 12664 Iziphumo 0.15 W / (mk) |

| Ukukhutshwa kwe-formaldehyde: | Iklasi E1 |EN 717 – 1:2006 Isiphumo 0.014 mg / m3 Imfuneko: Ngaphantsi kwe-3 ppm Isiphumo: 0.0053 ppm |

| Ukuxhathisa iSlip: | Uvavanywe kwi-BS 7967-2: 2002 (Uvavanyo lwe-Pendulum kumaxabiso e-PTV) I-Oiled Finish results: DRY (66) LOW RISK WET (29) EMNGENI EMNGCIPHEKO Akukho mfuneko yangoku yokumelana ne-slip kuphuhliso lweendawo zokuhlala. |

| Ukufaneleka kokusetyenziswa: | Ilungele ukusetyenziswa phantsi komgangatho wokufudumeza kwizicelo zorhwebo kunye neendawo zokuhlala |

| Iziphumo zokufuma: | Umgangatho owenziwe ngamaplanga uya kwanda ukuba ubekwe phantsi kweemeko ezinyusa ukufuma kwawo ngaphaya kwe-9%.Umgangatho wokhuni uya kucutheka ukuba iimeko ezikhoyo zinciphisa umthamo wokufuma kwemveliso ngaphantsi kwe-6%.Nakuphi na ukuvezwa ngaphandle kwezi parameters kuya kuphazamisa ukusebenza kwemveliso |

| Ukuhanjiswa kwesandi: | Umgangatho wokhuni ngokwawo uya kunika uncedo lokunciphisa ukuhamba kwesandi, kodwa kukwakhiwa komgangatho wonke kunye neendawo ezingqongileyo ezinegalelo kwimpembelelo kunye nesandi esisemoyeni.Uvavanyo oluchanekileyo kufuneka kuqeshwe injineli ukubala indlela yokufikelela kwiziphumo ezichanekileyo. |

| Iimpawu zobushushu: | Iibhodi zoMgangatho woMthi oSolid zibonelela ngala maxabiso alandelayo: Iibhodi ezingqindilili ezingama-20mm ezine4mm okanye 6mm zomaleko ongaphezulu ziya kulahlekelwa yi-0.10 K/Wm2 15mm iibhodi ezinomaleko ongaphezulu we-4mm okanye 6mm ziya kuphulukana no-0.08 K/Wm2 |

-

IWalnut yendalo iChevron Timber yoMgangatho woMthi

-

I-Chevron T&G Tshixa iGolide ye-Oak yobuNjineli boMbane...

-

Umgangatho ogqwesileyo we-Fishbone Fakela umgangatho wamaplanga e-Oak

-

Fishbone Dark Brown Walnut Engineering Timber F...

-

I-Wirebrush yeChevron Wood Flooring

-

15mm iChevron Oak yobunjineli bomgangatho womgangatho