Video

What is decorative acoustic wall panels ?

Acoustic Wall Panels are an ideal sound-absorbing decorative material. It has the advantages of sound absorption, environmental protection, flame retardant, heat insulation, heat preservation, moisture resistance, mildew resistance, easy dust removal, easy cutting, parquet, simple construction, good stability, good impact resistance, good independence, and high cost performance. A variety of colors are available to meet the needs of different styles and levels of sound-absorbing decoration.

Classified by material:

①Wood

Wooden sound-absorbing panels are exquisitely processed according to the principles of acoustics, and are composed of veneers, core materials and sound-absorbing thin felts. There are two types of wood sound-absorbing panels: split-slot wood sound-absorbing panels and perforated wood sound-absorbing panels.

②Mineral wool

The surface treatment of mineral wool sound-absorbing board has various forms, and the board has a strong decorative effect. The surface treated knurled mineral wool board, commonly known as "caterpillar", is covered with holes of different depths, shapes and diameters.

③Fabric

Fabric sound-absorbing board—the core material is centrifugal glass wool. Centrifugal glass wool, as a long-term and widely used acoustic material all over the world, has been proven to have excellent sound absorption properties.

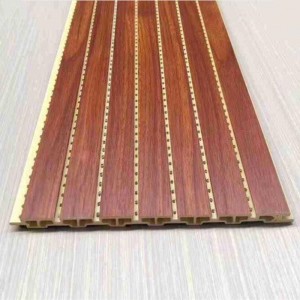

④WPC

WPC sound-absorbing panel is a revolutionary new type of environmentally friendly material. It is the most mature product of wood substitution technology in the world. It does not require any surface treatment. It is made by polymerizing a small amount of polymer materials and a large amount of wood powder through patented technology. Through the recycling of wood, the comprehensive utilization rate of wood is greatly improved, and there is no pollution in the production process. At the same time, it also solves the problem of recycling of waste resources in the plastics and wood industries, which is very in line with the energy conservation advocated by the state to establish a conservation-oriented society The major policy of reducing emissions.

Advantage:

(1) Large board surface and high flatness

(2) The board has high strength and light weight

(3) Good sound absorption, fireproof and waterproof

(4) Easy to install, each board can be disassembled and replaced separately

(5) The size, shape, surface treatment and color can be customized according to customer needs to meet the individual needs of customers

Where are the products mainly used:

Used in grand theaters, concert halls, movie theaters, recording studios, studios, monitoring rooms, conference rooms, gymnasiums, exhibition halls, dance halls, KTV rooms, family movie hall factories, silent rooms, courts, lecture halls, interrogation rooms, etc. Sound-absorbing

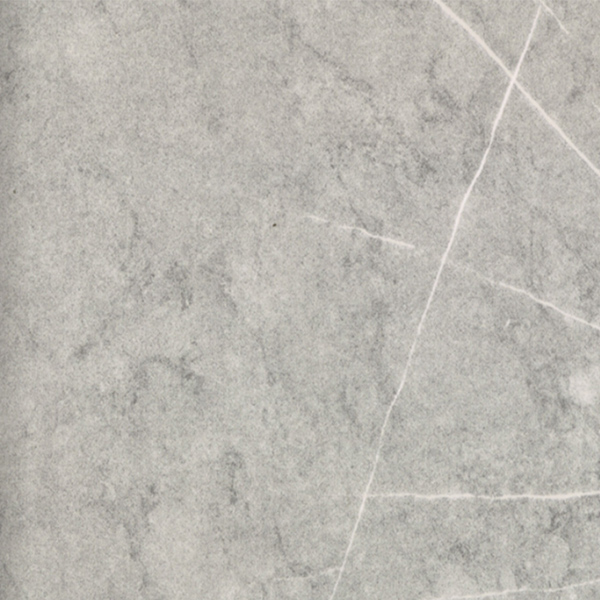

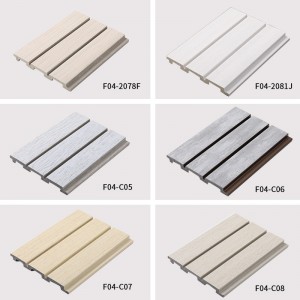

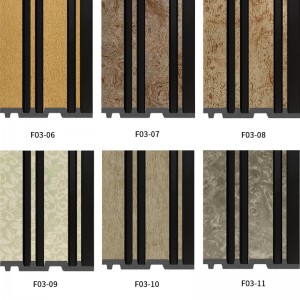

Interior Wall Panel is one kind It is a wall decoration material, the main material is wood-plastic material (wpc), a new environmentally friendly material. wood color, cloth pattern, stone colors are available for choose, and it has the advantages of waterproof, termite, silent, easy install, etc. Widely used in home improvement and commercial places

Interior Panel Parameter

| Product name | Indoor Wpc Wall |

| Model | Sound-absorbing Wall Panels |

| Size | 2900*210*12mm |

| Surface | Pvc Film Laminated |

| Material | WPC: Wood Pvc Composite. A mix of wood flour and poly ethylene with the addition of certain additives |

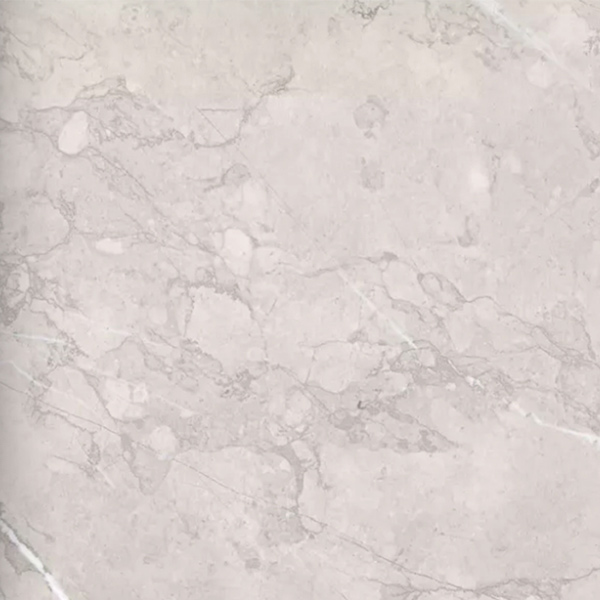

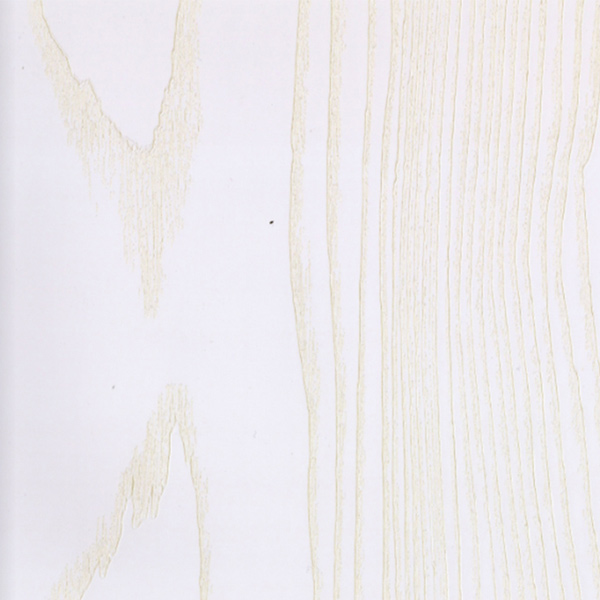

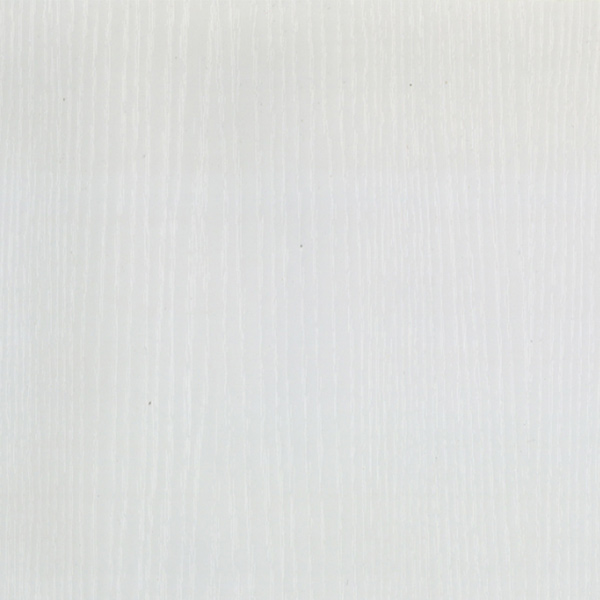

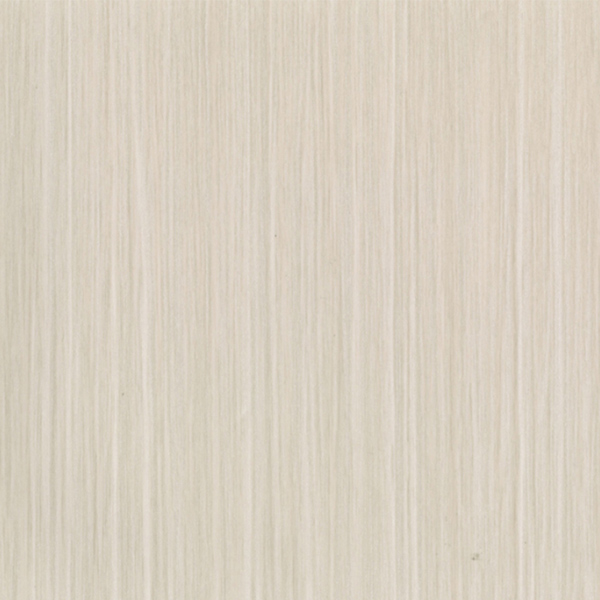

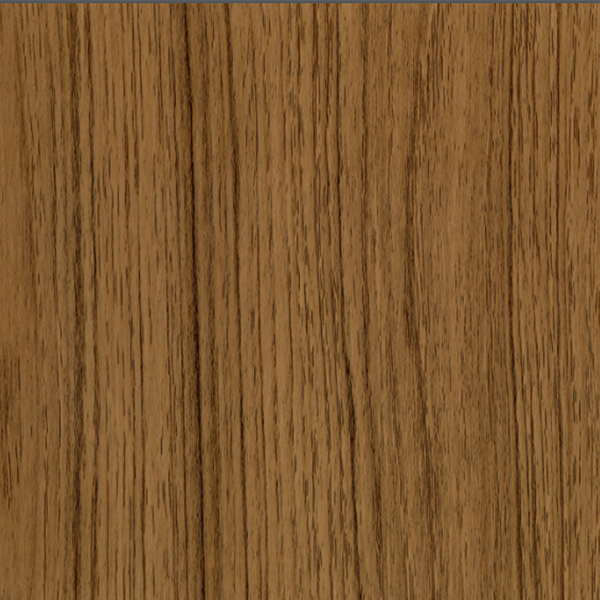

| Color | Oak,Gold, Mahogany, Teak, Cedar, Red , Classic grey, Black walnut |

| Minimum order | Full 20ft Container , 500 meters per Color |

| Package | Standard canton |

| Water absorption | Less than 1% |

| Flame- retardant level | Level B |

| Payment term | 30%T/T in advance,remainder 70% paid before shipment |

| Delivery period | Within 30 days |

| Remark | The color and the size can be changed according to your request |

| Application

Advantage

|

Hotels, commercial buildings, hospital, schools, home kitchen, bathroom, interior decoration and so on |

| 1) Dimensional stability, longevity, natural feel | |

| 2) Resistance to rot and crack | |

| 3) Stable over a wide temperature range, weather-resistant | |

| 4) Moisture resistant, low flame spread | |

| 5) High impact resistant | |

| 6) Outstanding screw and nail retention | |

| 7) Environmentally friendly, recyclable | |

| 8) Broad range of finished and appearance | |

| 9) Easily produced and easily fabricated | |

| 10) Contains no toxic chemicals or preservatives |

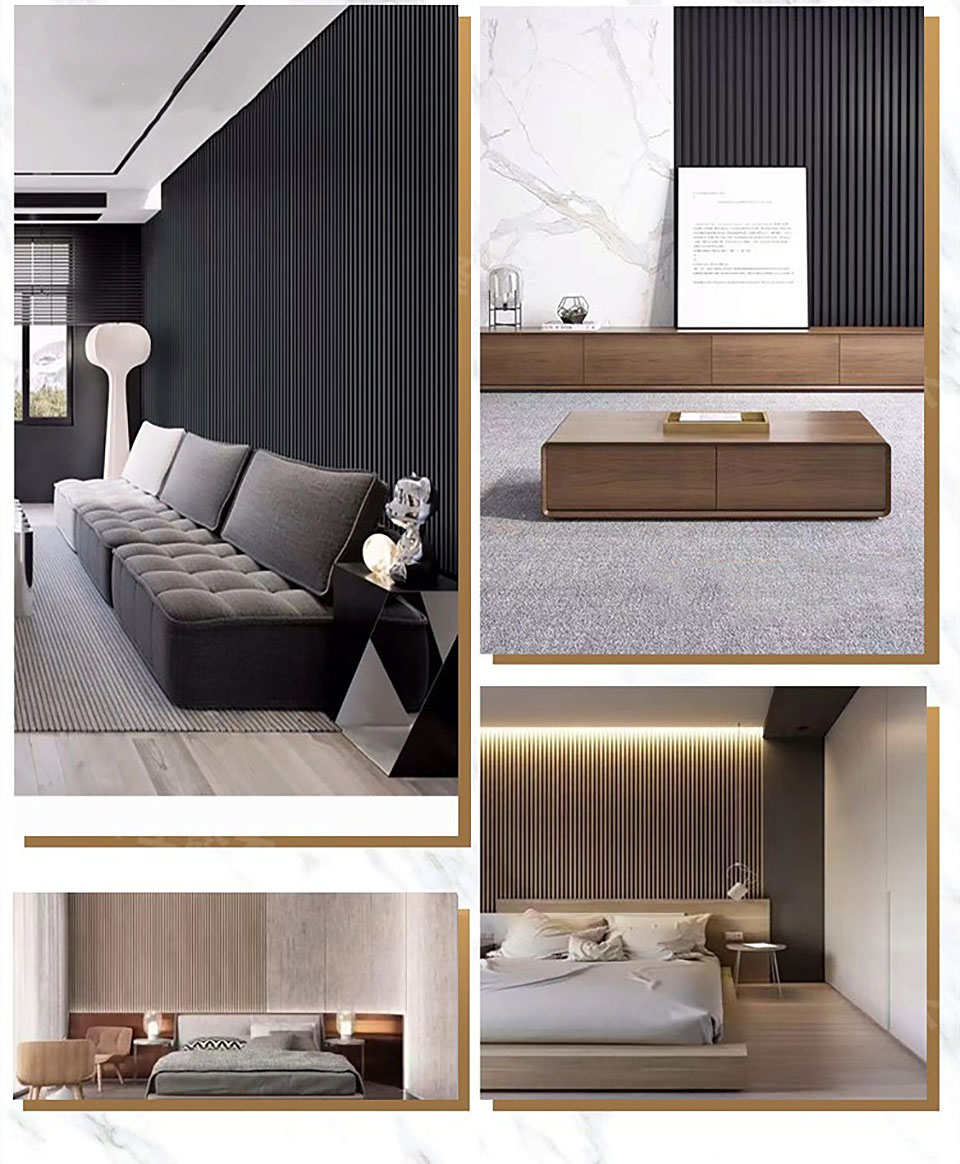

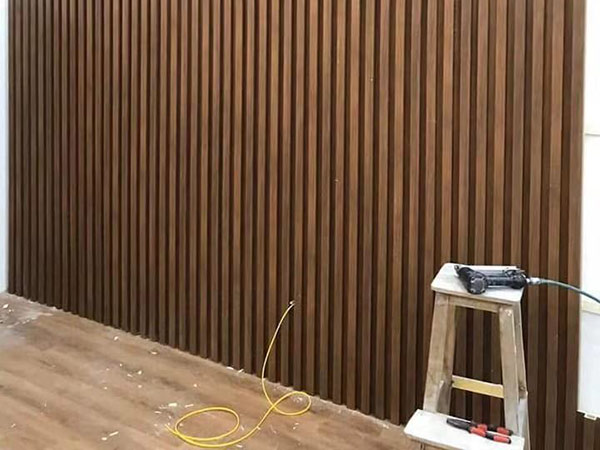

Interior Wall Panel Effect Picture

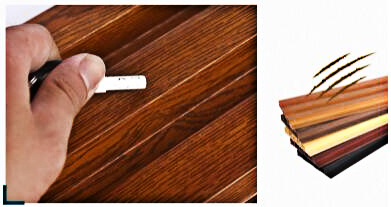

The Advantage of Wall Panel

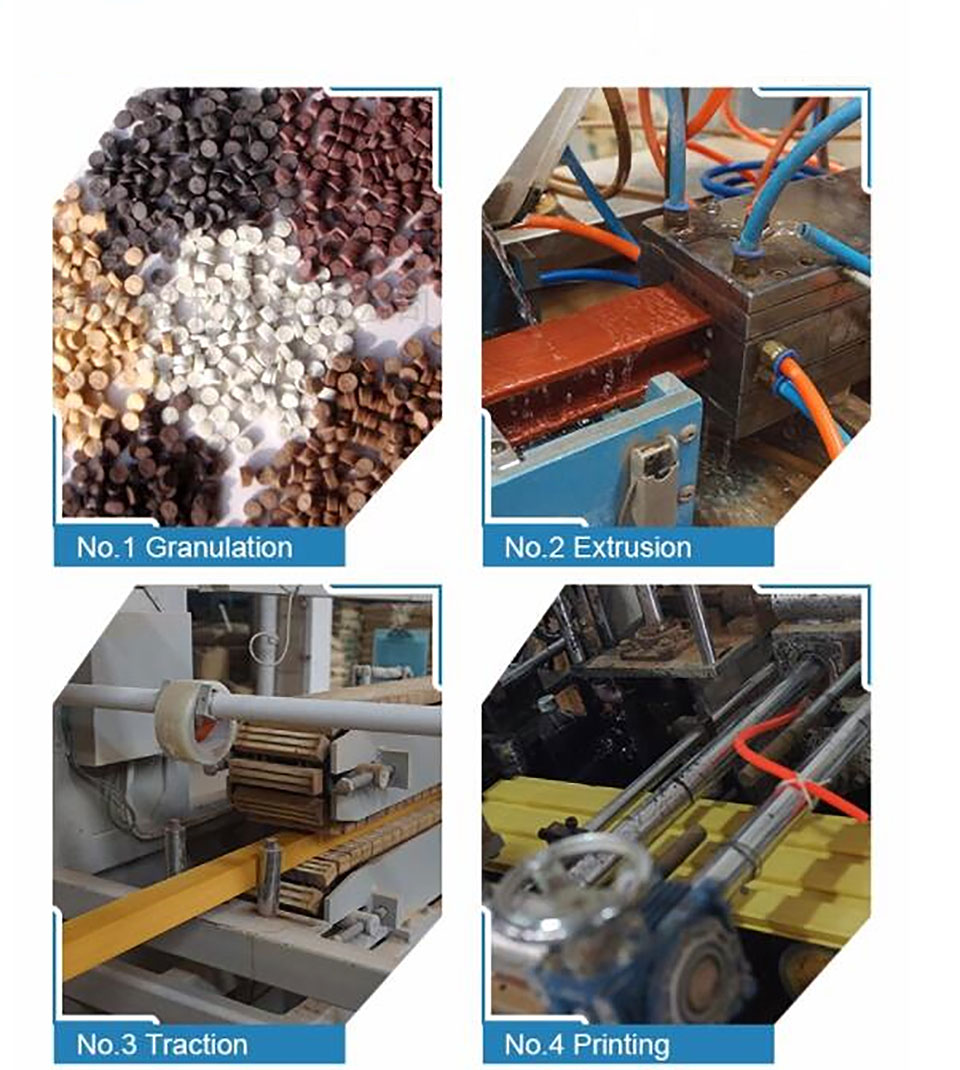

Wpc Wall Panel Production Process

Application

Project 1

Project 2

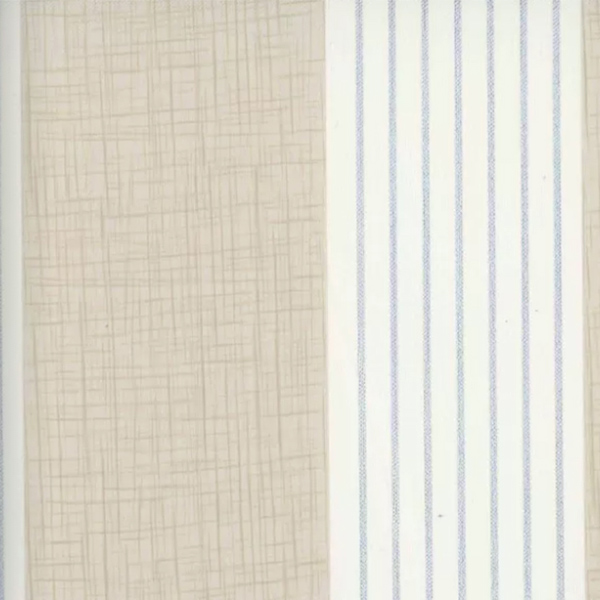

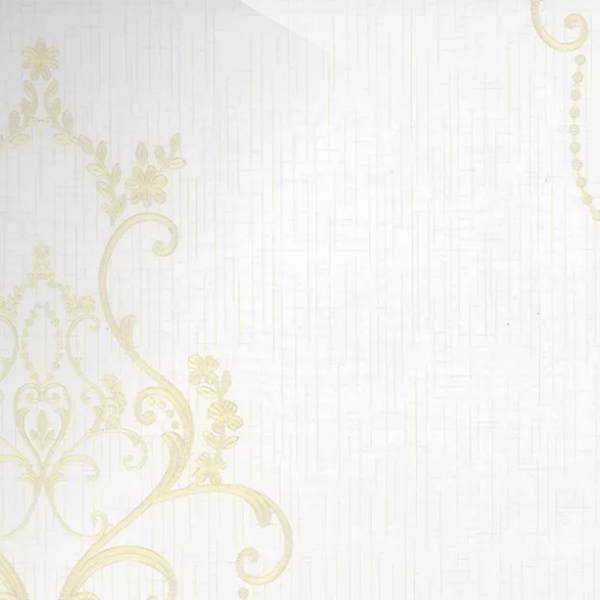

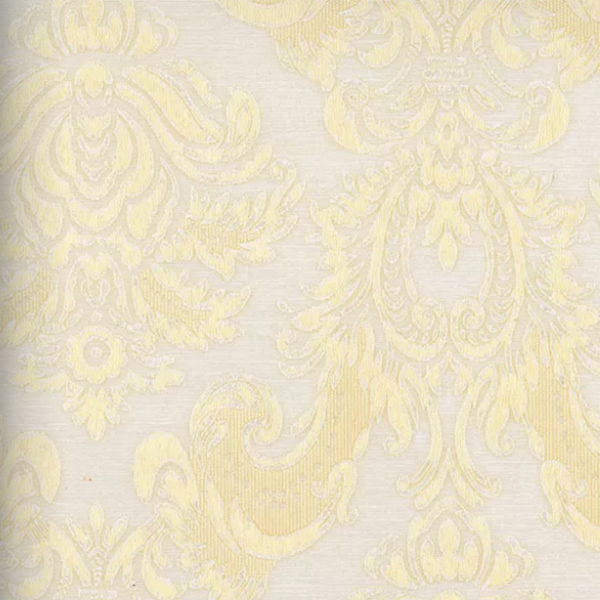

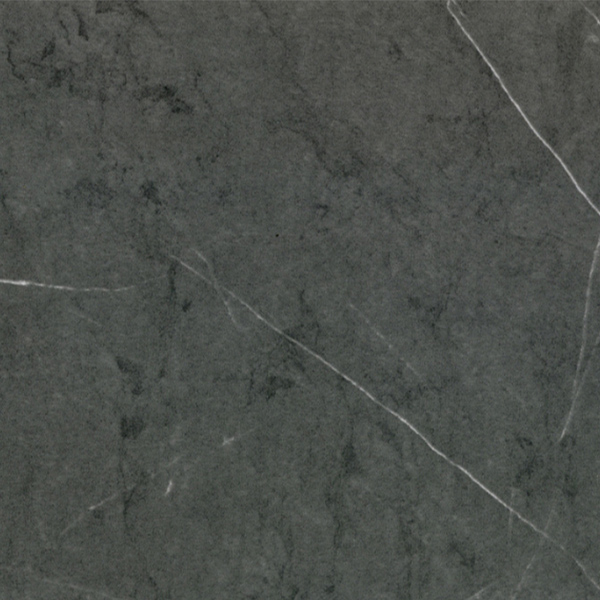

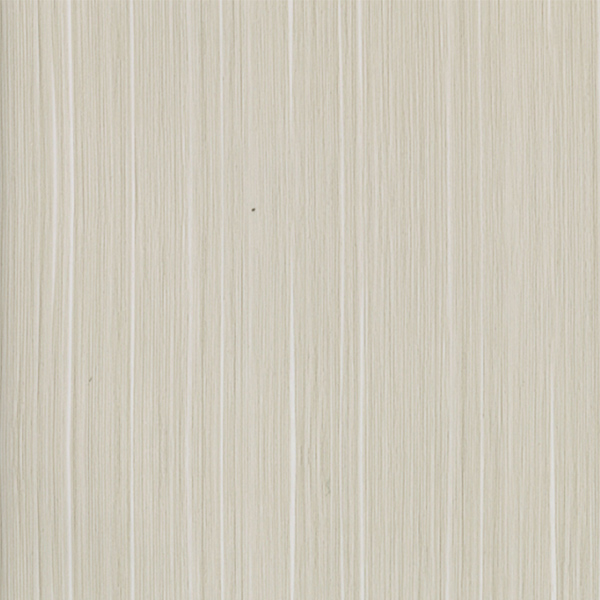

Cloth Colors

Cloth Colors

Installation

Installation

1.Interior Wpc cladding Panel Installation Video tutorial 1:

Directly Use an air nail gun directly to fix the nail on the edge of the wall panel lock to fix the wall

2.Interior Wpc Louvre Installation Video tutorial 2:

When the wall is uneven, apply styrofoam to the back of the Wpc Louvre board, and directly use an air nail gun to fix the nail on the edge of the wall panel lock to fix the wall

3.Indoor Wpc Wall Cladding Install Video tutorial 3:

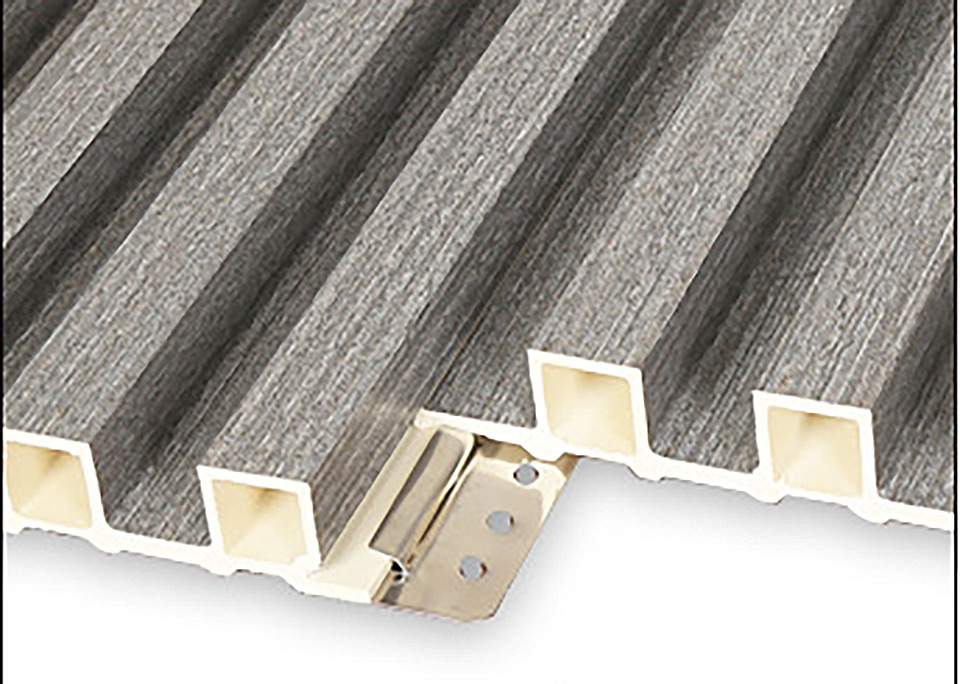

Fix the Wall Cladding lock directly through the metal clips, if the flatness of the wall meets the installation requirements

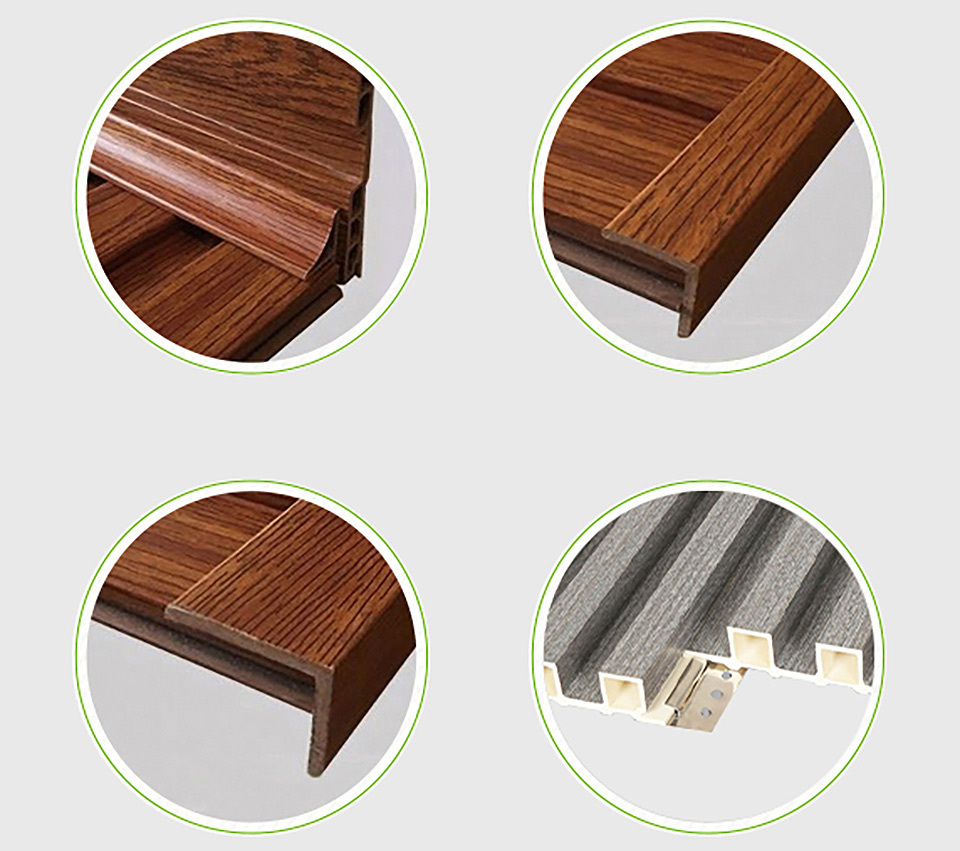

The Accessories for Wpc Wall

The Accessories for Wpc Wall

1.Concave Line

2.L Edge

3.Metal Clips

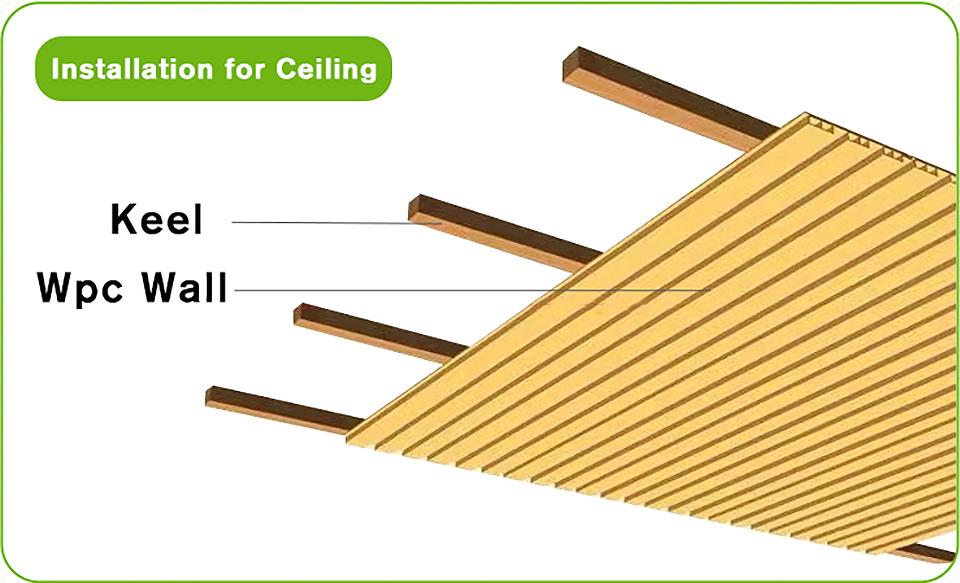

The Wpc Wall Installation for Wall and Ceiling

The Wpc Wall Installation for Wall and Ceiling

The first step is to confirm whether the wall is flat. If the wall is flat, you can install indoor wpc wall panels directly on the wall. If the wall is uneven, you need to install wooden keels on the wall as a support first, and the distance between each keel must be 25 cm apart.

In the second step, since the indoor wpc wall panel is click lock installation, it is only necessary to fix the wall panel to the wall or the keel through the metal clips

The third step, when the first wall panel is fixed in the second step, after the second wall is inserted into the first wall panel lock, repeat the second step to fix the wall panel on the wall or keel

The fourth step, repeat the third step

| No | Characteristic | Technology Target | Remark | |||||

| 1 | Appearance | No chipping, cracking, visual texture, delamination, bubbles, shallow embossing, scratches, dirt, poor cut, etc | ENEN649 | |||||

| 2 | Size mm (23℃) | Length | ± 0.20mm | EN427 | ||||

| Wide | ± 0.10mm | EN427 | ||||||

| Thickness | +0.13mm, -0.10mm | EN428 | ||||||

| Thickness Range | ≤0.15 mm | EN428 | ||||||

| wearlay Thickness | ± 0.02 mm | EN429 | ||||||

| 3 | Squareness mm | ≤ 0.15 | EN427 | |||||

| 4 | Crook mm | ≤ 0.15 | EN427 | |||||

| 5 | Microbevel Cut Angle | 8-15 degrees | ||||||

| Microbevel Cut Depth | 0.60 – 1.5 mm | |||||||

| 6 | Dimensional stability after exposure to heat | ≤ 0.12% | EN434 | |||||

| 7 | Curling after exposure to heat | WPC:≤0.2(70℃/6Hr) | EN434 | |||||

| SPC:≤0.2(80℃/6Hr) | ||||||||

| 8 | Gloss level | nominal value ± 1.5 | Lightmeter | |||||

| 9 | Taber Abrasion - Minimum | 0.5mm wear lay | ≥5000 cycles Average | EN660 | ||||

| 10 | Uv | 8~12g/m2 | ||||||

| 11 | ≥9N | |||||||

| SCRATCH PERFORMANCE UV | SCLEROMETER | |||||||

| 12 | Anti-stain performance | Iodine | 3 | Modified ASTM 92 | ||||

| Oil Brown | 0 | |||||||

| Mustard | 0 | |||||||

| Shope Polish | 2 | |||||||

| Blue Sharpie | 1 | |||||||

| 13 | Determination of flexibility | no crack | EN435 | |||||

| 14 | Peel Resistance | Length | ≥62.5N/5cm | EN431(62.5N/5cm,100mm/s) | ||||

| width | ≥62.5N/5cm | |||||||

| 15 | Residual indentation (average) mm | ≤0.15 | EN433 | |||||

| 16 | Color fastness: | ≥7 | ISO105-B2:2002 | |||||

| 17 | Locking Strength | fsmax ≥2 .5N/mm | ISO24344 | |||||