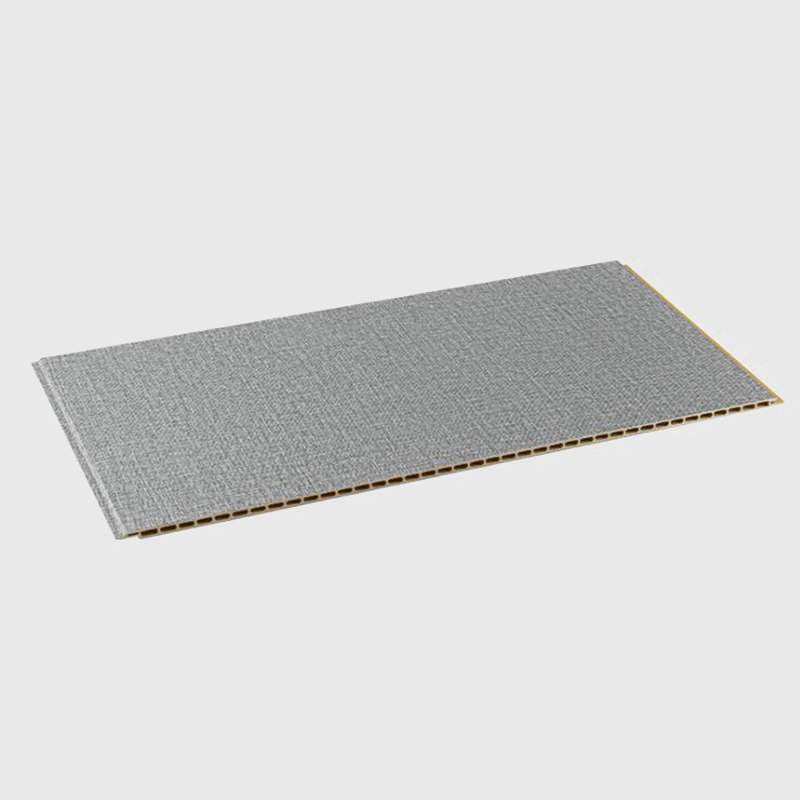

Interior Wpc Wall Panel and SPC Wall Panel Effect picture for Background Wall

China New SPC Shower wall panels

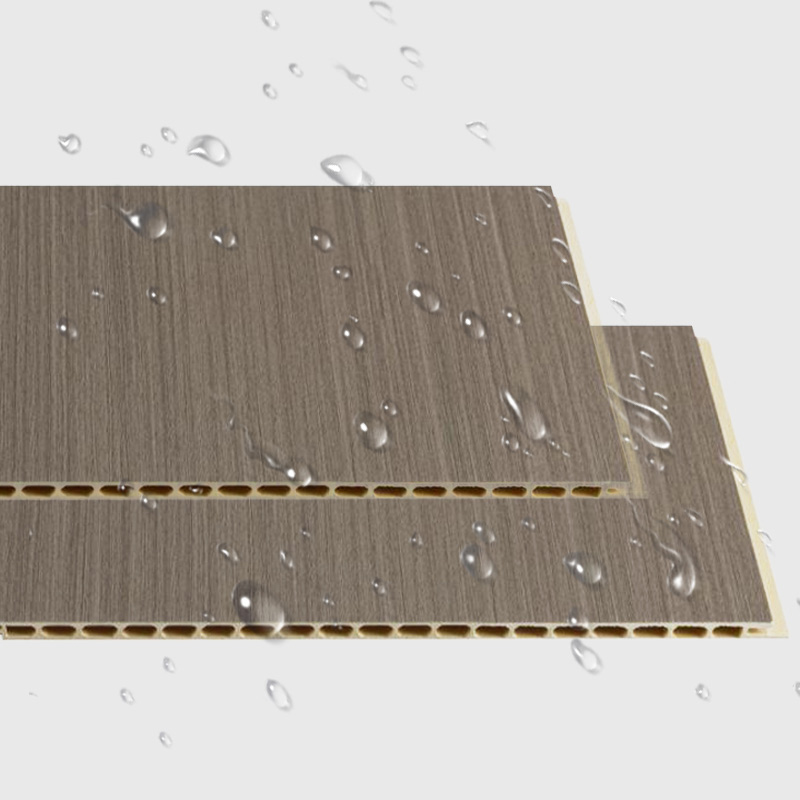

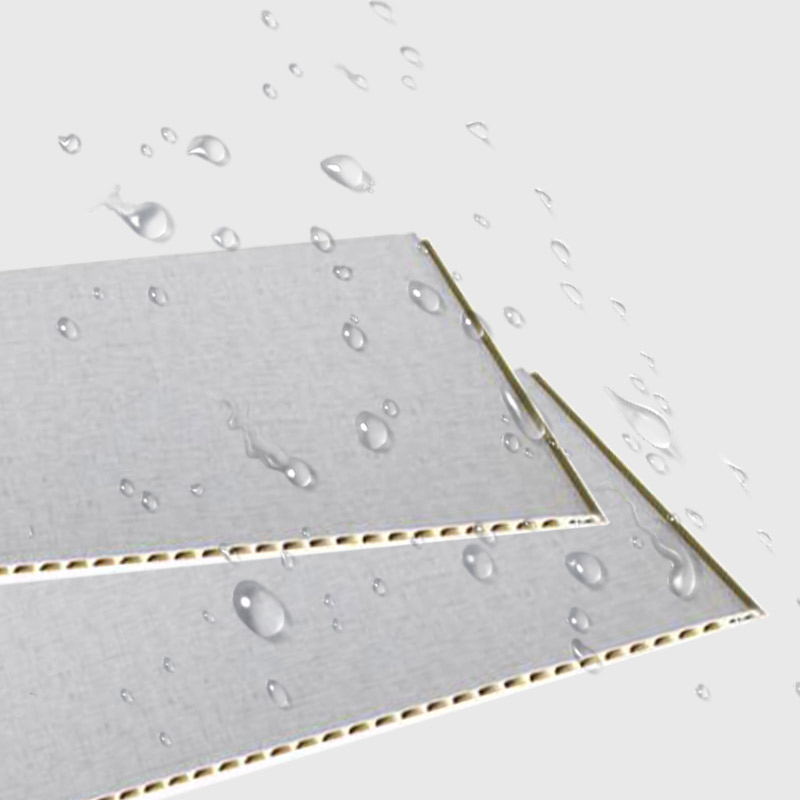

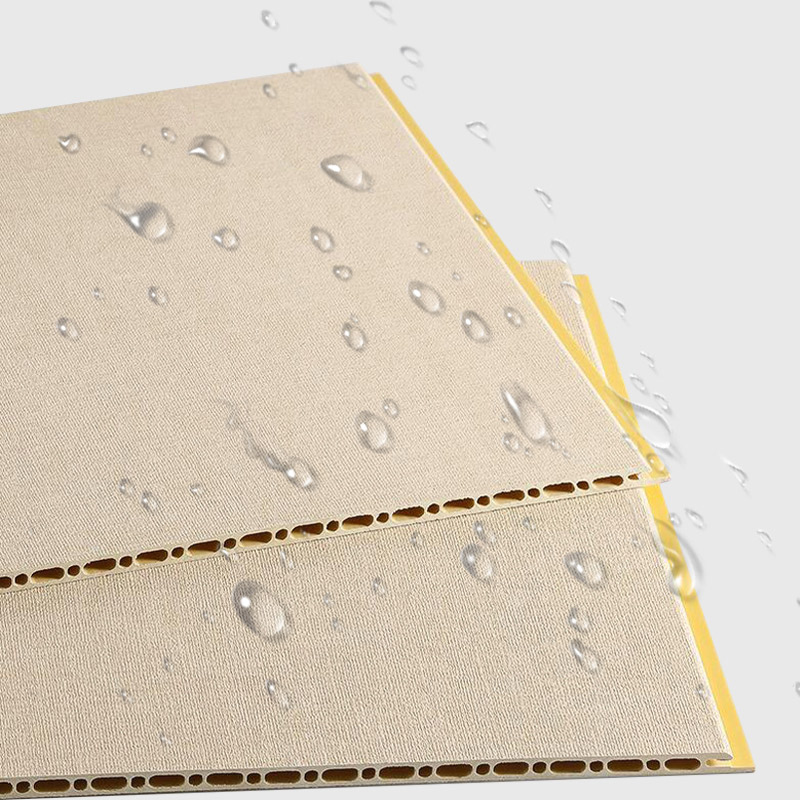

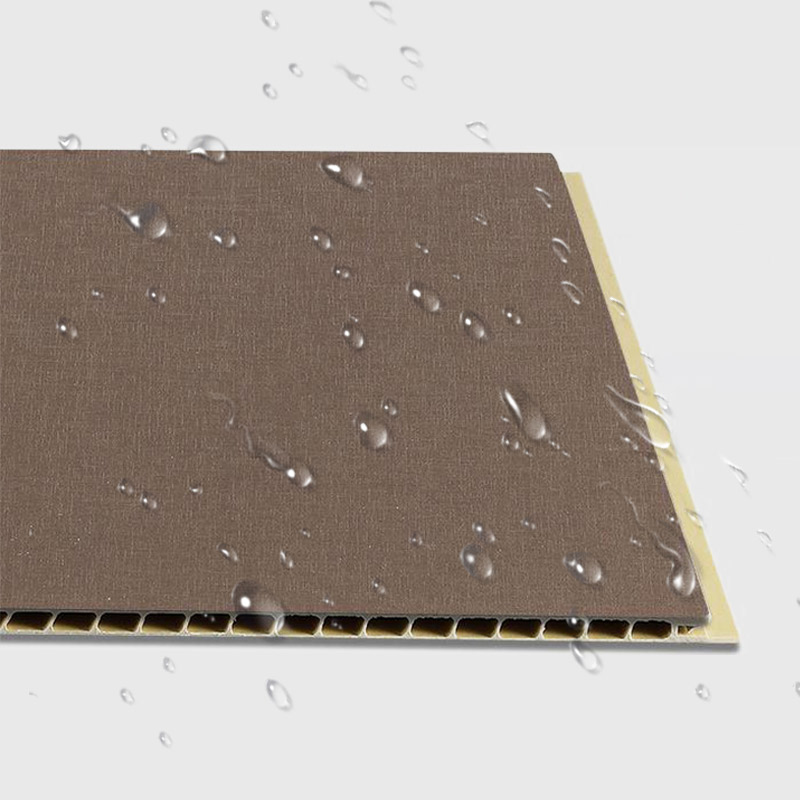

The bathroom is one of the most important rooms in a family, and it is also the most problematic place. Because this room is often exposed to water, it is very important to choose a good waterproof wall material. DEGE Shower wall panels use new spc materials.

What material is spc?

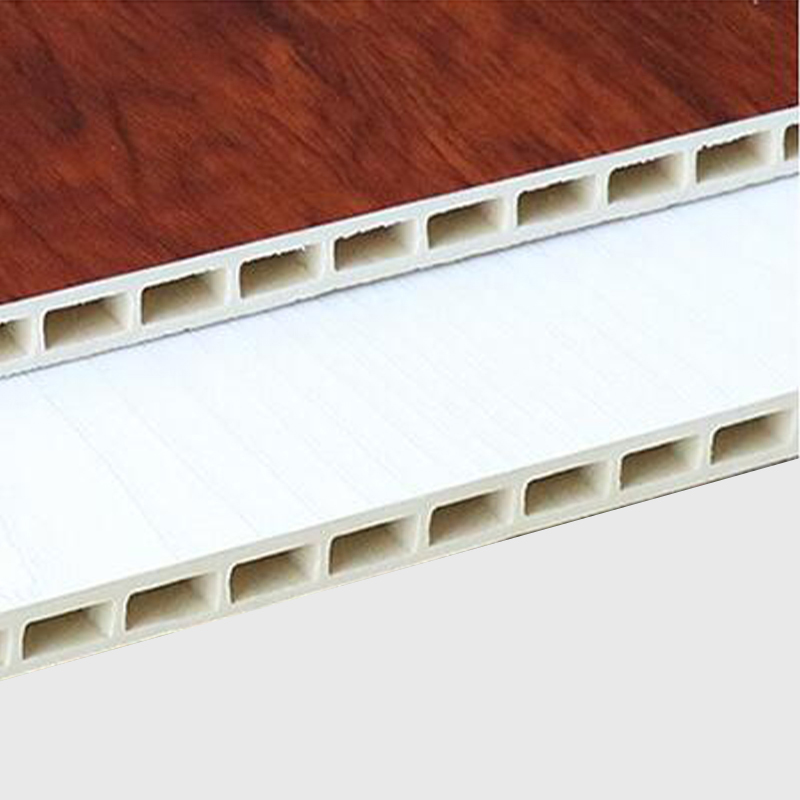

1. SPC is the abbreviation of Stone Plastic Composites, namely stone-plastic composites. Its main raw material is polyvinyl chloride resin, which is an SPC substrate extruded by an extruder combined with a T-die.

2. SPC wall panel is made by heating and laminating and embossing PVC color film and SPC base material with a three-roll or four-roll calender, respectively, and no glue is used in the production process.

Main advantages of SPC bathroom wall panel

1. Environmentally friendly, non-toxic and renewable resources, 100% free of formaldehyde, lead, benzene, heavy metals and carcinogens.

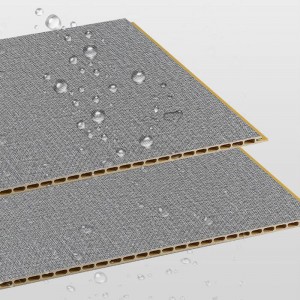

2. Polyvinyl chloride has no affinity with water, and will not be mildewed due to high humidity, and will not deform due to moisture.

3. The fire rating of SPC floor is B1, which is second only to the existence of stone. It will automatically extinguish after leaving the flame for five seconds. It is flame-retardant and non-combustible, and will not produce toxic and harmful gases.

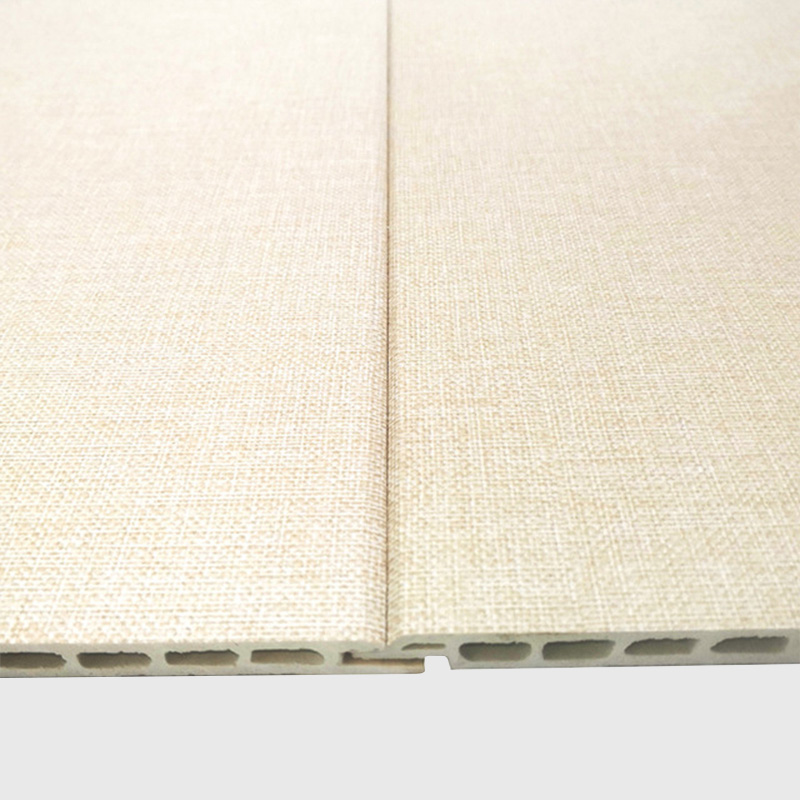

4. Convenient installation. The special snap-fit assembly method makes the seams tighter and smoother, which overcomes the shortcomings of large seams of other materials and unevenness after installation.

5. It adopts a hollow structure and a small heat transfer coefficient, which is only one-thousandth of that of aluminum. The heat preservation effect is significant, especially for air-conditioning environments.

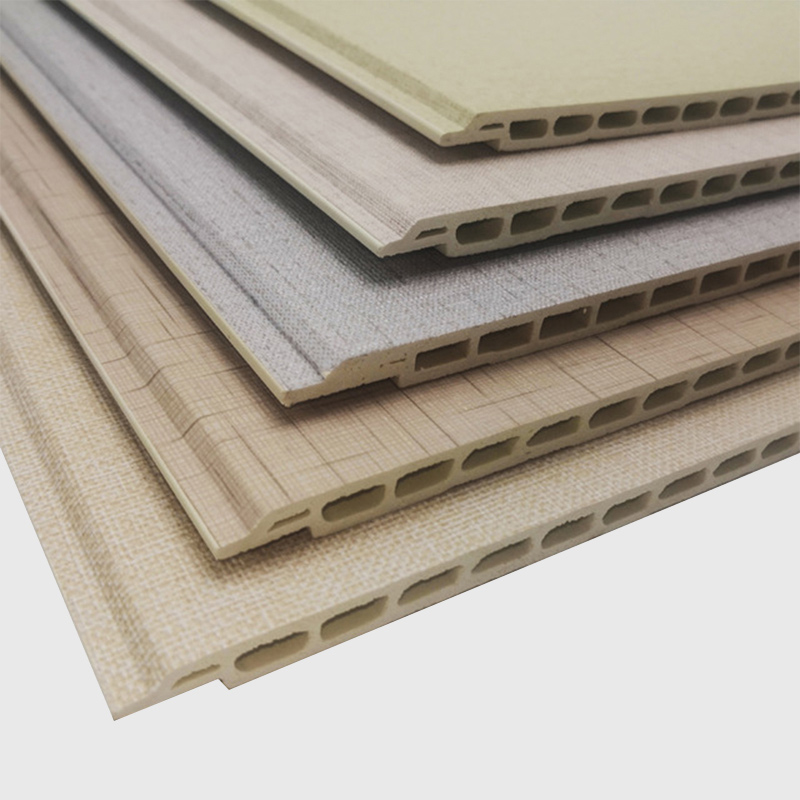

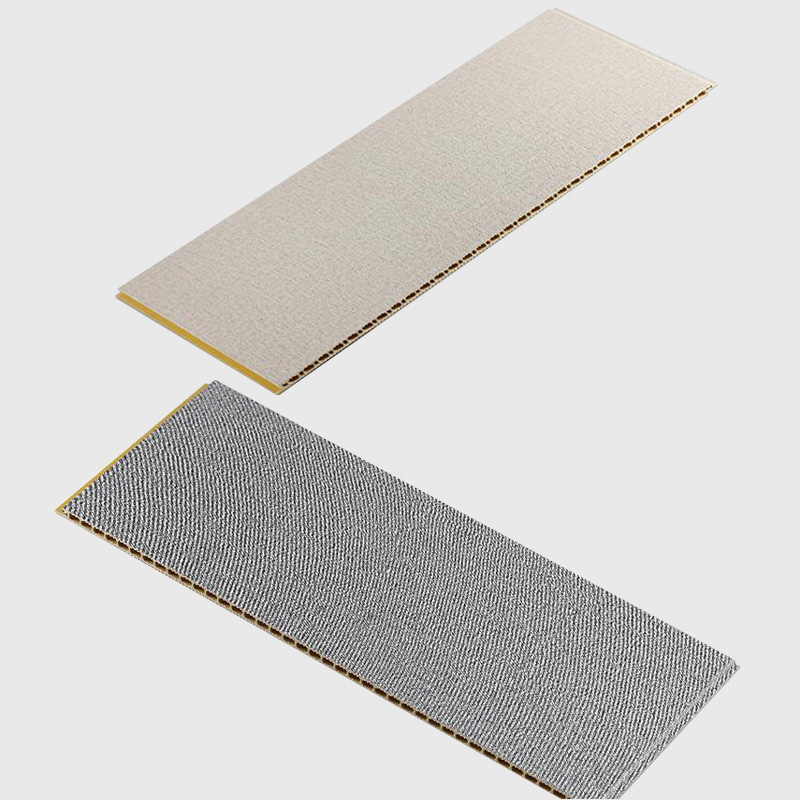

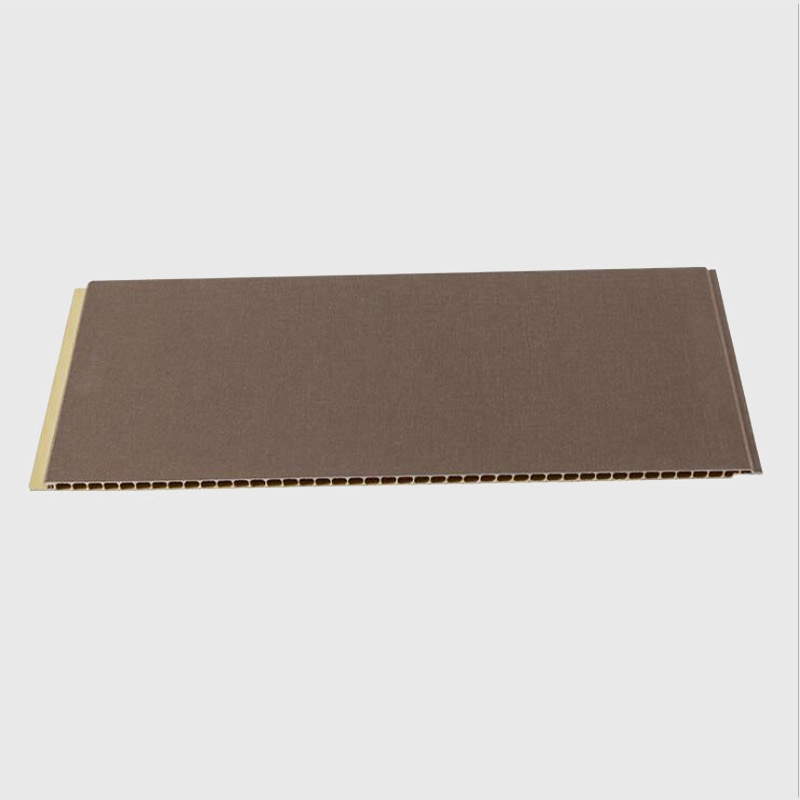

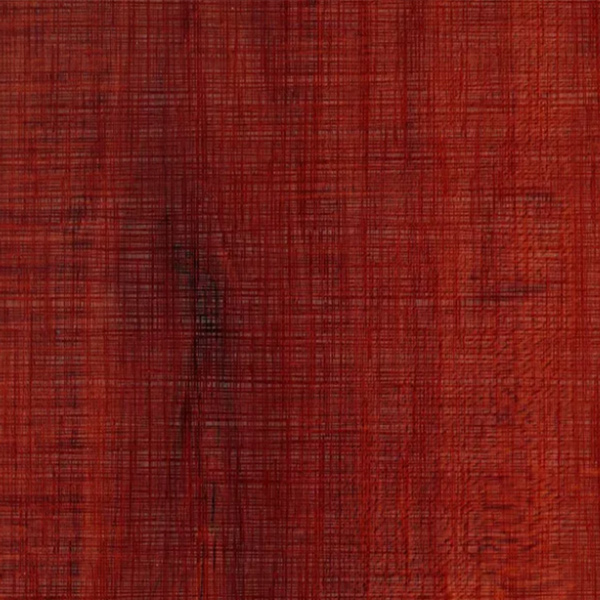

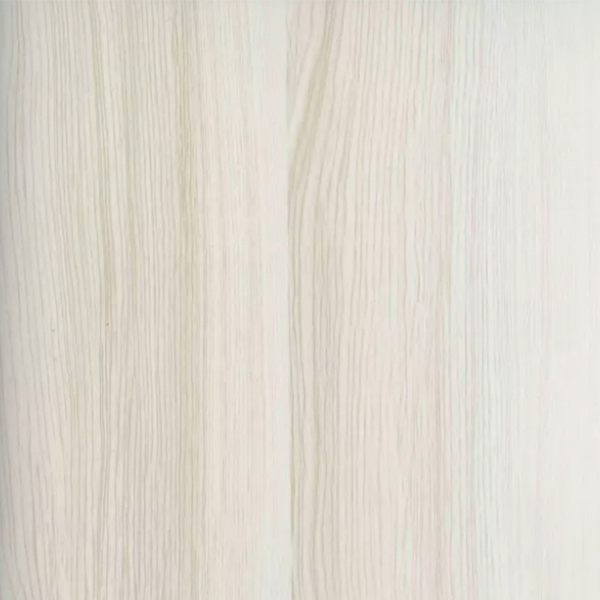

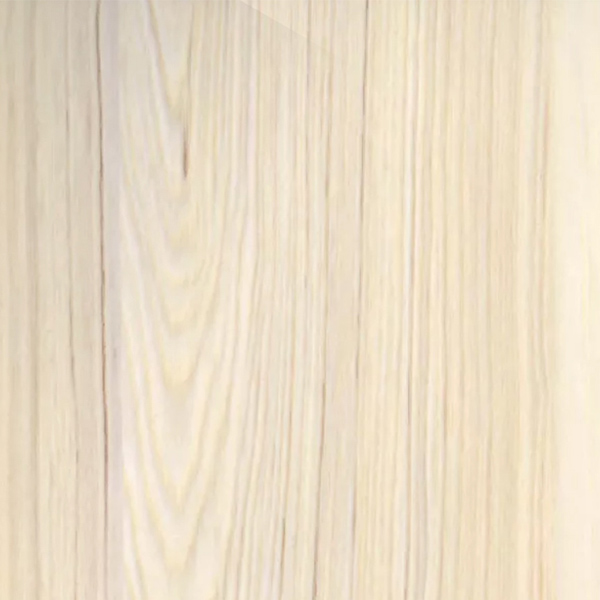

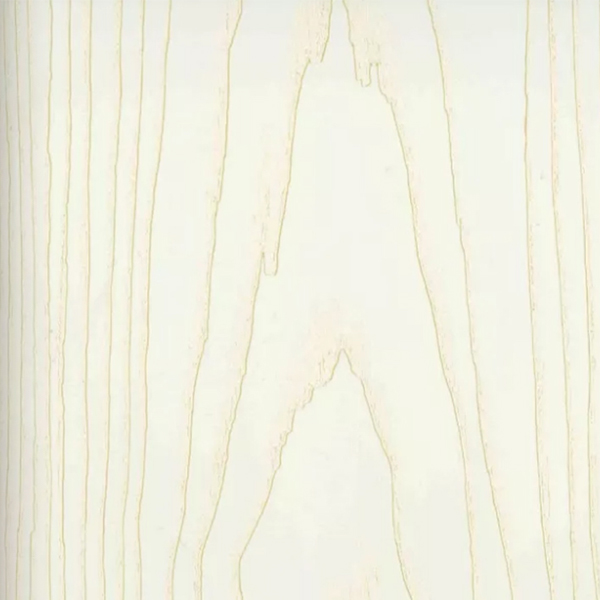

6. Since the surface is a decorative layer of pvc color, all colors are varied, such as stone grain, wood grain, solid color, cloth grain, wallpaper texture, etc.

Multiple Colors

Size

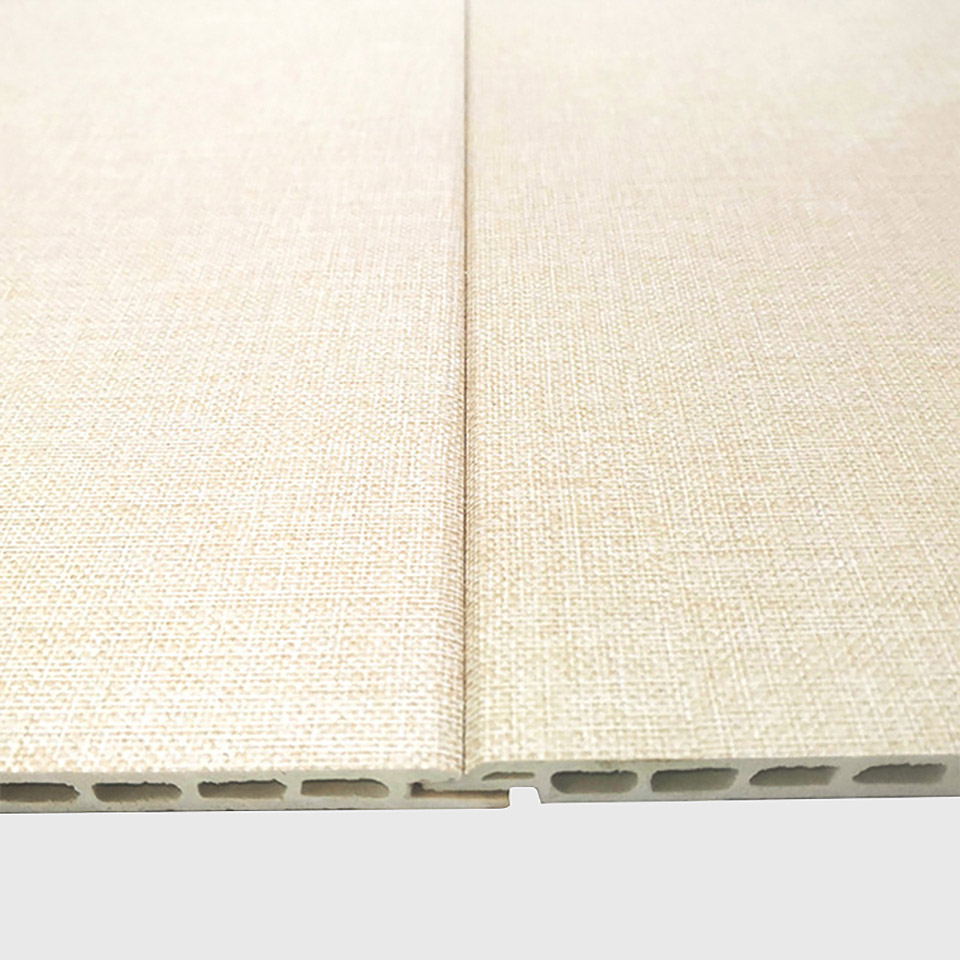

Detail Image

Joint Tyle

Specification

| Product name | Indoor Spc Wall , Interior Spc Wall Panel, |

| Brand | DEGE |

| Hs code | 3925900000 |

| Model | Cloth Design Wall Panels |

| Size | 400*7mm |

| Lenghth | 2.8 Meter or or Customized |

| Surface | Pvc Film Laminated |

| Material | SPC: Stone Pvc Composite.PVC resin powder, light calcium powder and other auxiliary materials |

| Color | Oak,Gold, Mahogany, Teak, Cedar, Red , Classic grey, Black walnut |

| Minimum order | Full 20ft Container , 500 meters per Color |

| Package | Standard canton |

| Water absorption | Less than 1% |

| Flame- retardant level | Level B |

| Payment term | 30%T/T in advance,remainder 70% paid before shipment |

| Delivery period | Within 30 days |

| Remark | The color and the size can be changed according to customer request |

| Application

Advantage

|

Hotels, commercial buildings, hospital, schools, home kitchen, bathroom, interior decoration and so on |

| 1) Dimensional stability, longevity, natural feel | |

| 2) Resistance to rot and crack | |

| 3) Stable over a wide temperature range, weather-resistant | |

| 4) Moisture resistant, low flame spread | |

| 5) High impact resistant | |

| 6) Outstanding screw and nail retention | |

| 7) Environmentally friendly, recyclable | |

| 8) Broad range of finished and appearance | |

| 9) Easily produced and easily fabricated | |

| 10) Contains no toxic chemicals or preservatives |

Advantage

Finished Goods Image

Applications

Project

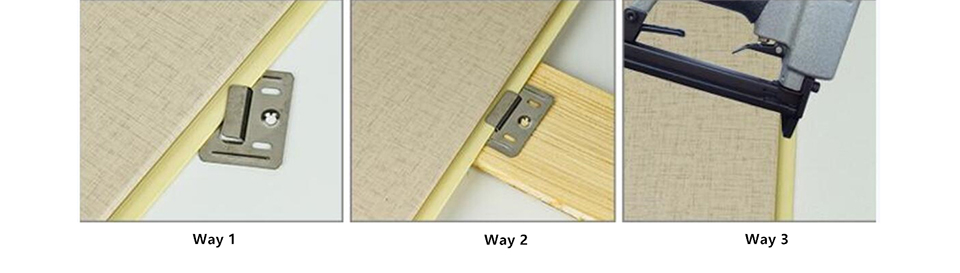

Wall Panel Installation

Wall Panel Installation

Way 1: Nail the wall panel directly to the wall through the metal cllip

Way 2: Install the keel on the wall first, and directly nail the wall panel to the keel through the metal clip

Way 3: Nail the wall panel to the wall directly with an air nail gun

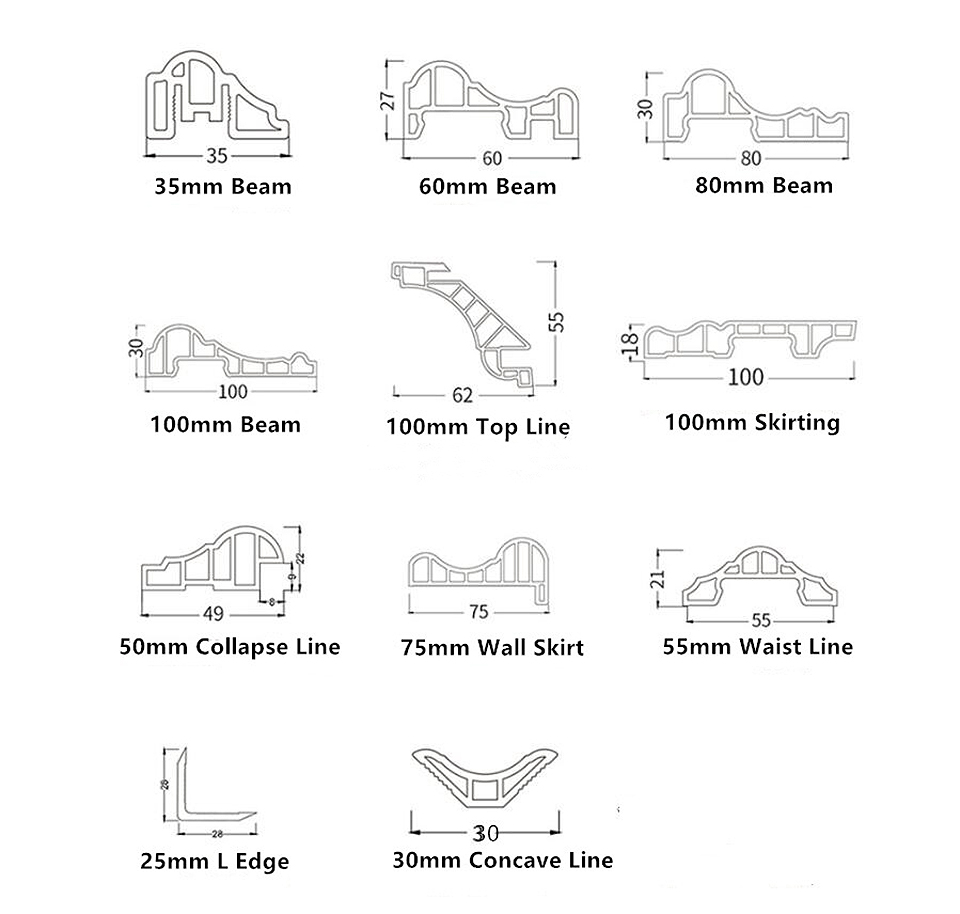

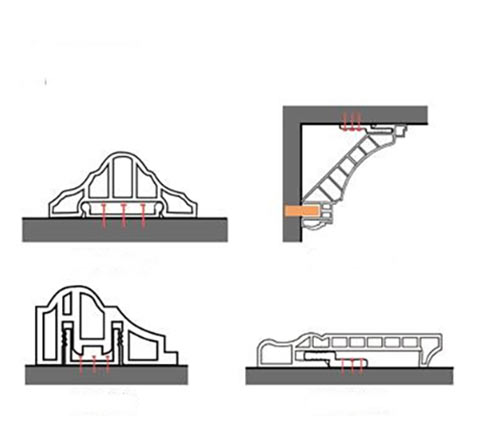

Wall Panel Accessories Design and Installation

Wall Panel Accessories Design and Installation

Installation tips:

Fix the Pvc Buckle on the wall first, then snap the accessories into the pvc Buckle

| Characteristic | Test Specification and Result |

| Squareness | ASTM F2055 – Passes – 0.020 in. max |

| Size and Tolerance | ASTM F2055 – Passes – +0.015 in per linear foot |

| Thickness | ASTM F386 – Passes – Nominal +0.006 in. |

| Flexibility | ASTM F137 – Passes – ≤1.1 in., no cracks or breaks |

| Dimensional Stability | ASTM F2199 – Passes – ≤ 0.025 in. per linear foot |

| Heavy Metal Presence / Absence | EN 71-3 C — Meets Spec. (Lead, Antimony, Arsenic, Barium, Cadmium, Chromium, Mercury and Selenium). |

| Smoke Generation Resistance | EN ISO 9239-1 (Critical Flux) Results 9.2 |

| Smoke Generation Resistance, Non-Flaming Mode | EN ISO |

| Flammability | ASTM E648- Class 1 Rating |

| Residual Indentation | ASTM F1914 – Passes – Average less than 8% |

| Static Load Limit | ASTM-F-970 Passes 1000psi |

| Requirements for Wear Group pr | EN 660-1 Thickness Loss 0.30<I<0.60 prEN 660-2 Volume Los 7.6<F <15.0 |

| Slip Resistance | ASTM D2047 – Passes – > 0.6 Wet, 0.6 Dry |

| Resistance to Light | ASTM F1515 – Passes – ∧E ≤ 9 |

| Resistance to Heat | ASTM F1514 – Passes – ∧E ≤ 9 |

| Electrical Behavior (ESD) | EN 1815: 1997 2,0 kV when tested at 23 C+1 C |

| Underfloor Heating | Suitable for installing over under floor heating. |

| Curling After Exposure to Heat | EN 434 < 1.8mm pass |

| Recycled Vinyl Content | Approximately 40% |

| Recyclability | Can be recycled |

| Product Warranty | 10-Year Commercial & 15-Year Residential |

| Floorscore Certified | Certificate Provided Upon Request |