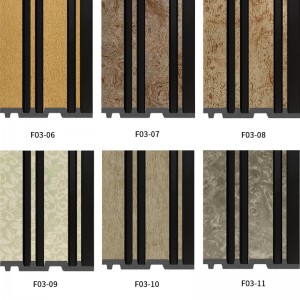

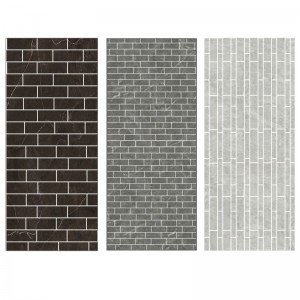

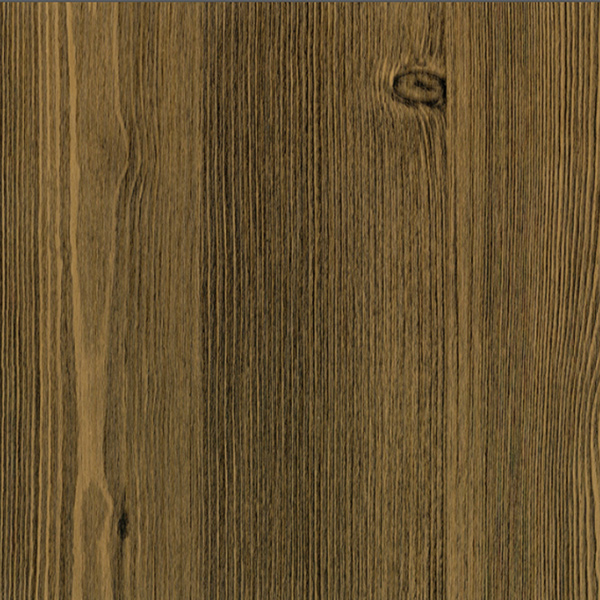

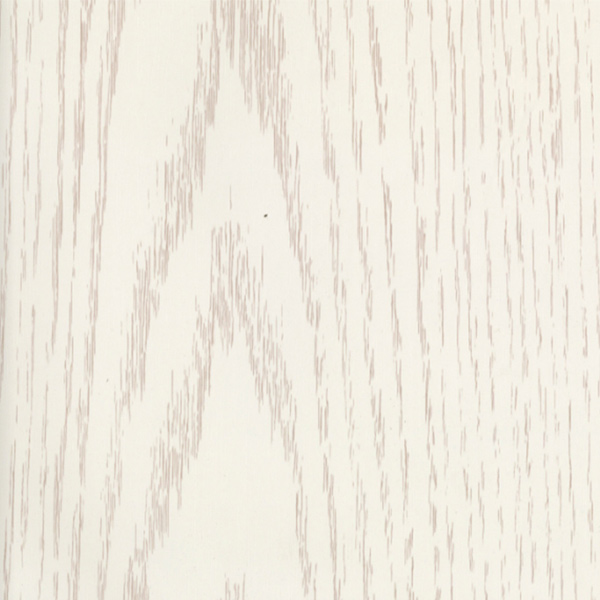

Multiple Colors

Size

Detail Image

Specification

| Dimension | Name | UV SPC SHEET or SPC SINTERED STONE |

| Material | 42%PVC resin+55%Calcium+3%Additive Composite | |

| Size | 4X8FT (1220*2440mm) | |

| Thickness | 1.5mm/2.0mm/2.5mm/2.7mm/3.0mm/3.5mm/4.0mm/5.0mm/6.0mm | |

| Designs | More than 500 designs(custom made designs by 3D print) | |

| Technology | Extrusion Plate+Hot stamping Film+UV coating | |

| Function | Type | Wall & Furniture cabinet&Ceiling PVC marble sheet |

| Feature | Waterproof; Fireproof; Moisture-proof; | |

| Advantage | Bendable; Wear-resisting; Sunscreen | |

| Application | Furniture cabinet, interior wall decoration such asrestaurant, hotel, supermarket, kitchen, living roomand so on. | |

| Installation | 1.Glue on the furniture cabinet or wall,2.Aluminum trim profile 3. Sealant installation |

|

| Service | Certification | ISO9001, CE, SGS |

| Sample | Free samples available | |

| Min Order | 100 PCS | |

| Packing | Wooden pallet + corner protection + metal strap. | |

| Delivery Time | Shipped in 5-15 days after payment |

Package list

| Common Thickness For Reference | ||||

| Thickness(mm) | Tolerance (mm) | Weight(kg/pc) | Tolerance(kg) | MOQ(20GP/pcs) |

| 1.3mm | +-0.05 | 8.0kg/pc | +-0.5 | 3000pcs |

| 1.5mm | +-0.05 | 8.2kg/pc | +-0.5 | 2700pcs |

| 2.0mm | +-0.05 | 12.3kg/pc | +-0.5 | 2000pcs |

| 2.5mm | +-0.05 | 15.3kg/pc | +-0.5 | 1600pcs |

| 2.8mm | +-0.05 | 17.2kg/pc | +-0.5 | 1400pcs |

| 3.0mm | +-0.05 | 18.4kg/pc | +-0.5 | 1300pcs |

| 3.2mm | +-0.05 | 19.6kg/pc | +-0.5 | 1250pcs |

| 3.5mm | +-0.05 | 21.5kg/pc | +-0.5 | 1150pcs |

| 4.0mm | +-0.05 | 24.5kg/pc | +-0.5 | 1000pcs |

| 5.0mm | +-0.05 | 30.7kg/pc | +-0.5 | 800pcs |

| 6.0mm | +-0.05 | 36.8kg/pc | +-0.5 | 650pcs |

Advantage

A. 100% Waterproof

B. Environmental friendly

C. Fire prevention

WPC Wall Sheet Series

Finished Panel Colors

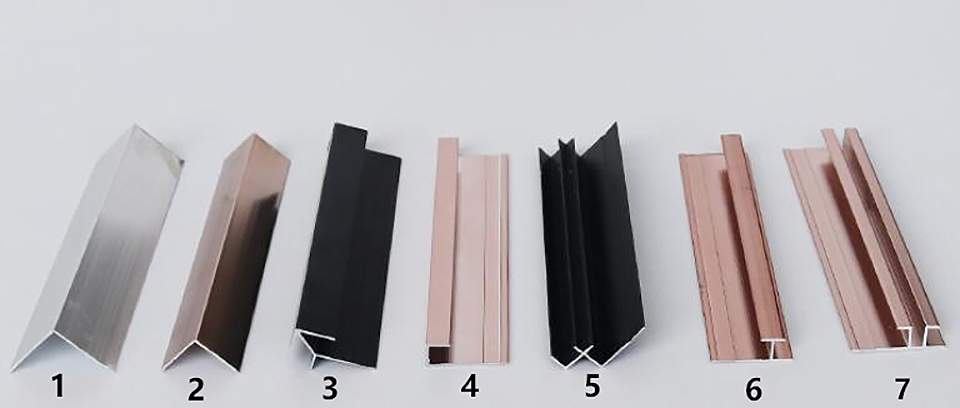

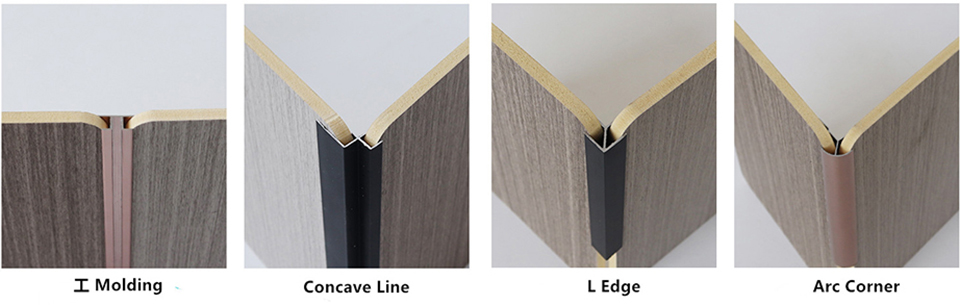

Accessories

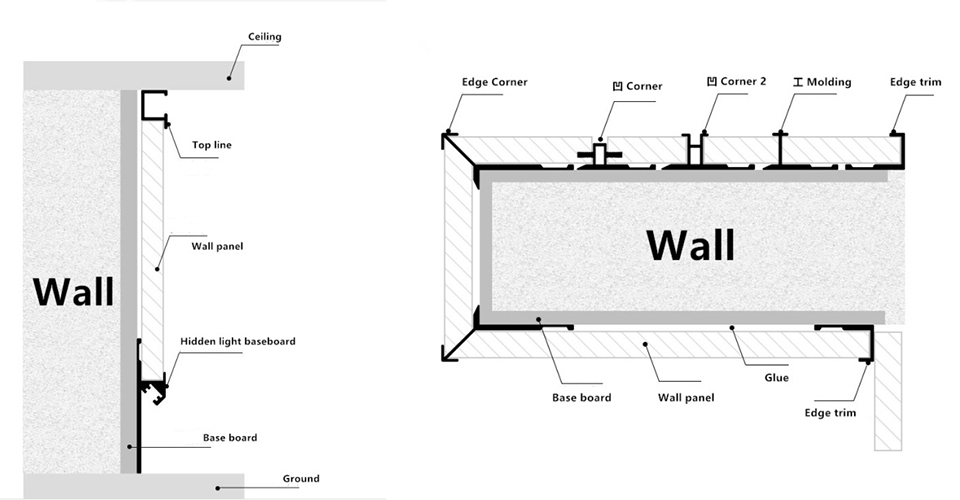

Installation

Production Process And Wordshop

1.Raw materials: resin, calcium powder, stabilizer, etc.

2.After mixing and extruding raw materials, the Spc wall sheet is formed in one piece

3.Uv treatment, surface gloss adjustment, it will be like marble finish

4.Packing and Palletizing

Applications

How to bend WPC Wall Sheet the arc package column ?

How to bend WPC Wall Sheet the arc package column ?

How to install WPC WALL Panels?

How to install WPC WALL Panels?

How to bend Wood-Plastic Wall sheet?

How to bend Wood-Plastic Wall sheet?

Installation diagram:

Installation diagram:

Installation tips:

Installation tips:

First fix the aluminum decorative line on the wall or base board with steel nails or self-tapping screws, install the decorative panel, and fix it with glue on the back

Installation example:

Installation example:

| No | Characteristic | Technology Target | Remark | |||||

| 1 | Appearance | No chipping, cracking, visual texture ,delamination, bubbles, shallow embossing, scratches, dirt, poor cut, etc | ENEN649 | |||||

| 2 | Size mm (23℃) | Length | ± 0.20mm | EN427 | ||||

| Wide | ± 0.10mm | EN427 | ||||||

| Thickness | +0.13mm, -0.10mm | EN428 | ||||||

| Thickness Range | ≤0.15 mm | EN428 | ||||||

| wearlay Thickness | ± 0.02 mm | EN429 | ||||||

| 3 | Squareness mm | ≤ 0.15 | EN427 | |||||

| 4 | Crook mm | ≤ 0.15 | EN427 | |||||

| 5 | Microbevel Cut Angle | 8-15 degrees | ||||||

| Microbevel Cut Depth | 0.60 – 1.5 mm | |||||||

| 6 | Dimensional stability after exposure to heat | ≤ 0.12% | EN434 | |||||

| 7 | Curling after exposure to heat | WPC:≤0.2(70℃/6Hr) | EN434 | |||||

| SPC:≤0.2(80℃/6Hr) | ||||||||

| 8 | Gloss level | nominal value ± 1.5 | Lightmeter | |||||

| 9 | Taber Abrasion - Minimum | 0.5mm wear lay | ≥5000 cycles Average | EN660 | ||||

| 10 | Uv | 8~12g/m2 | ||||||

| 11 | ≥9N | |||||||

| SCRATCH PERFORMANCE UV | SCLEROMETER | |||||||

| 12 | Anti-stain performance | Iodine | 3 | Modified ASTM 92 | ||||

| Oil Brown | 0 | |||||||

| Mustard | 0 | |||||||

| Shope Polish | 2 | |||||||

| Blue Sharpie | 1 | |||||||

| 13 | Determination of flexibility | no crack | EN435 | |||||

| 14 | Peel Resistance | Length | ≥62.5N/5cm | EN431(62.5N/5cm,100mm/s) | ||||

| width | ≥62.5N/5cm | |||||||

| 15 | Residual indentation (average) mm | ≤0.15 | EN433 | |||||

| 16 | Color fastness: | ≥7 | ISO105-B2:2002 | |||||

| 17 | Locking Strength | fsmax ≥2 .5N/mm | ISO24344 | |||||