Carbonized Bamboo Floor

What is Strand Woven Bamboo Flooring ?

Strand Woven Bamboo Flooring is made of natural high-quality bamboo as raw material, and is made of high temperature and high pressure after special harmless treatment. It has a super anti-moth function. With the natural texture of bamboo, it has both the natural beauty of log floors and the strong and durable advantages of ceramic floor tiles.

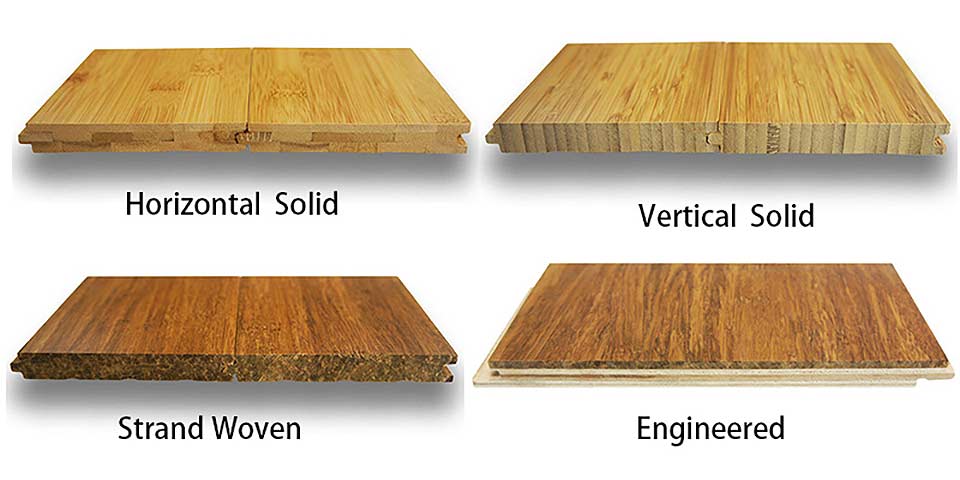

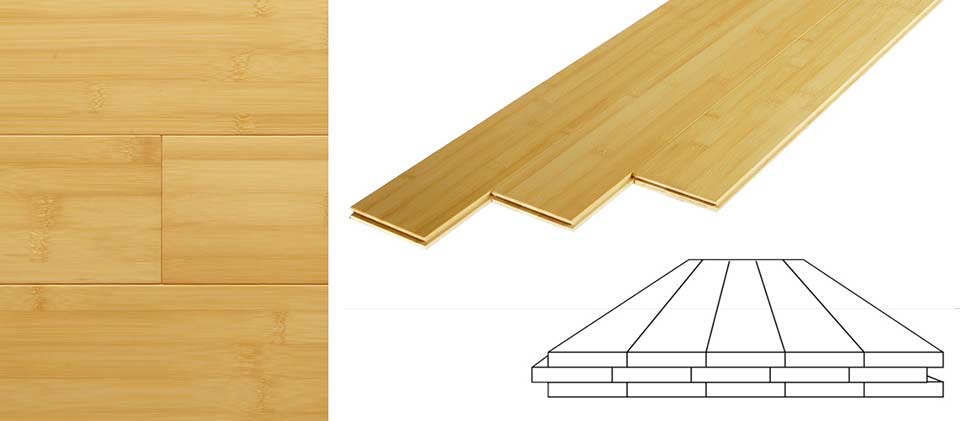

According to the surface structure, bamboo flooring can be divided into three categories: radial bamboo flooring-lateral pressure bamboo flooring; string surface bamboo flooring-flat pressure bamboo flooring; and reorganized bamboo flooring. According to the processing method of bamboo flooring, it can be divided into natural bamboo flooring and carbonized bamboo flooring. The natural color bamboo floor maintains the original color of the bamboo, and the bamboo strips of the carbonized bamboo floor must undergo high temperature and high pressure carbonization treatment to deepen the color of the bamboo slices and make the color of the bamboo slices uniform.

Flooring is a very important part of home decoration. Whether it is the quiet and delicate color of bamboo floor or the tactile enjoyment it brings to people, it is a home decoration that is very suitable for home life. It gives people a fresh and refined feeling. It is flexible. , Good stability, suitable for all ages. And the beautiful natural and delicate appearance of bamboo flooring, used for home decoration, is simply a visual feast. Bamboo flooring is made through layers of processing. Relatively speaking, bamboo flooring is quite different from ordinary flooring, especially in terms of texture and shape. Bamboo flooring has more advantages than average in terms of price. The floor is a bit more expensive. Of course, bamboo flooring also has the natural advantages of being warm in winter and cool in summer.

Structure

Natural Bamboo Flooring

Carbonized Bamboo Flooring

Natural Carbonized Bamboo Floor

Bamboo Flooring Advantage

Details Images

Bamboo Flooring Technical Data

| 1) Materials: | 100% Raw Bamboo |

| 2) Colors: | Strand Woven |

| 3) Size: | 1840*126*14mm / 960*96*15mm |

| 4) Moisture content: | 8%-12% |

| 5) Formaldehyde emission: | Up to E1 standard of Europe |

| 6) Varnish: | Treffert |

| 7) Glue: | Dynea |

| 8) Glossiness: | Matt, Semi gloss |

| 9) Joint: | Tongue & Groove (T& G) click ; Unilin+Drop click |

| 10) Supply ability: | 110,000m2 / month |

| 11) Certificate: | CE Certification , ISO 9001:2008, ISO 14001:2004 |

| 12) Packing: | Plastic films with carton box |

| 13) Delivery Time: | Within 25 days after received advance payment |

Click System Available

A: T&G Click

T&G LOCK BAMBOO-Bamboo Florinig

Bamboo T&G -Bamboo Florinig

B: Drop (short side)+ Unilin click (length side)

drop Bamboo Florinig

unilin Bamboo Florinig

Bamboo flooring package list

| Type | Size | Package | NO Pallet/20FCL | Pallet/20FCL | Size of Box | G.W. | N.W. |

| Carbonized Bamboo | 1020*130*15mm | 20pcs/ctn | 660 ctns/1750.32 sqm | 10 plt, 52ctns/plt,520ctns/1379.04 sqms | 1040*280*165 | 28kgs | 27kgs |

| 1020*130*17mm | 18pcs/ctn | 640 ctns/1575.29 sqm | 10 plt, 52ctns/plt,520ctns/1241.14 sqms | 1040*280*165 | 28kgs | 27kgs | |

| 960*96*15mm | 27pcs/ctn | 710 ctns/ 1766.71 sqm | 9 plt, 56ctns/plt,504ctns/1254.10 sqms | 980*305*145 | 26kgs | 25kgs | |

| 960*96*10mm | 39pcs/ctn | 710 ctns/ 2551.91 sqm | 9 plt, 56ctns/plt,504ctns/1810.57 sqms | 980*305*145 | 25kgs | 24kgs | |

| Strand Woven Bamboo | 1850*125*14mm | 8pcs/ctn | 672 ctn, 1243.2sqm | 970*285*175 | 29 kg | 28 kg | |

| 960*96*15mm | 24pcs/ctn | 560 ctn, 1238.63sqm | 980*305*145 | 26 kg | 25 kg | ||

| 950*136*17mm | 18pcs/ctn | 672ctn, 1562.80sqm | 970*285*175 | 29 kg | 28kg |

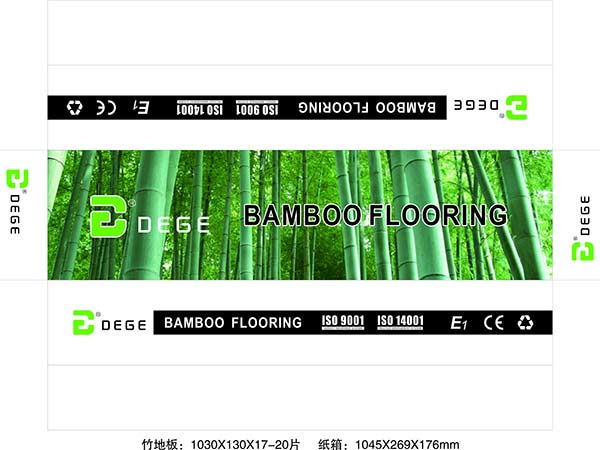

Packaging

Dege Brand Packaging

General Packaging

Transportation

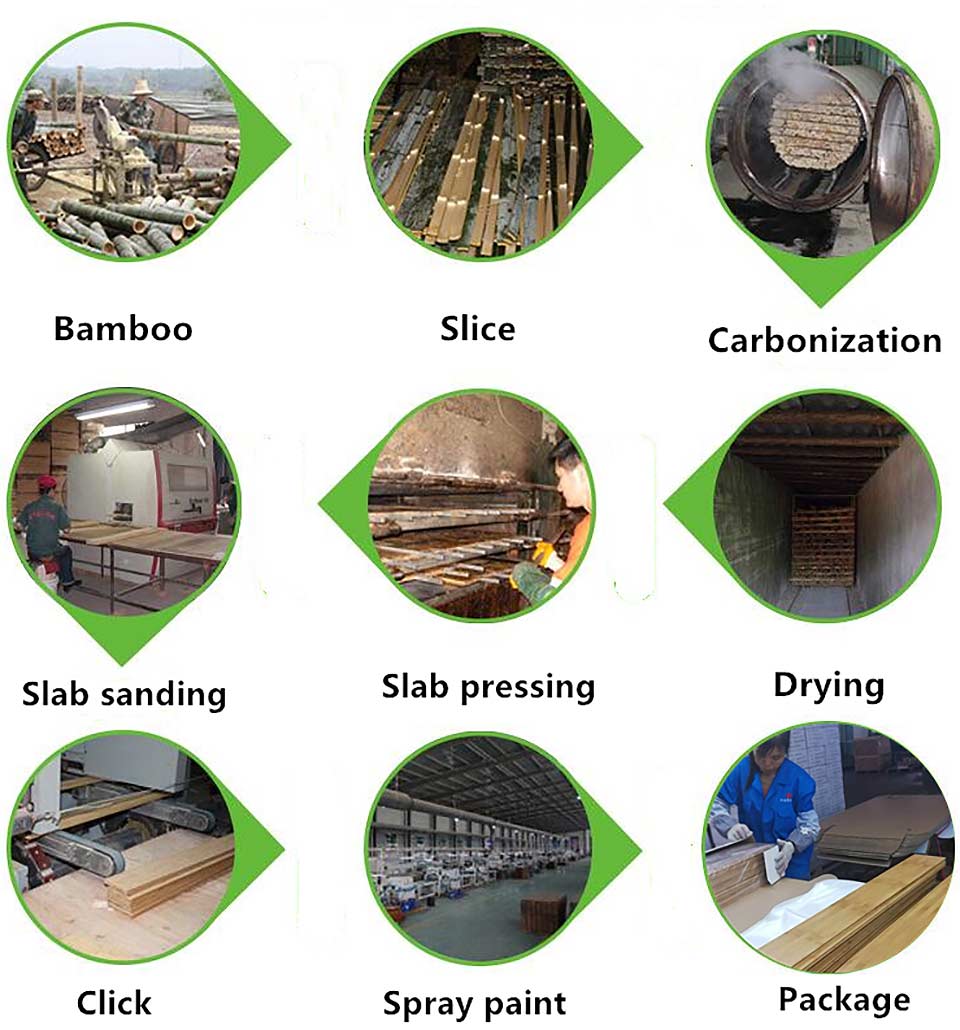

Product Process

Applications

How is bamboo floor installed (detailed version)

How is bamboo floor installed (detailed version)

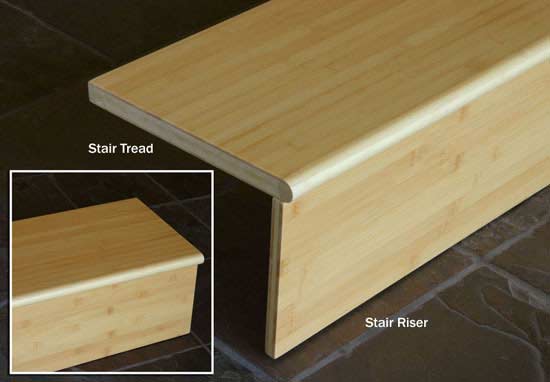

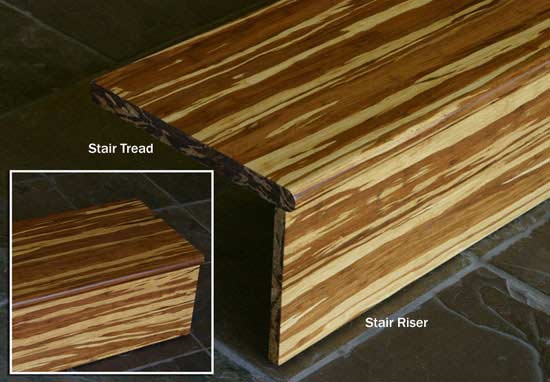

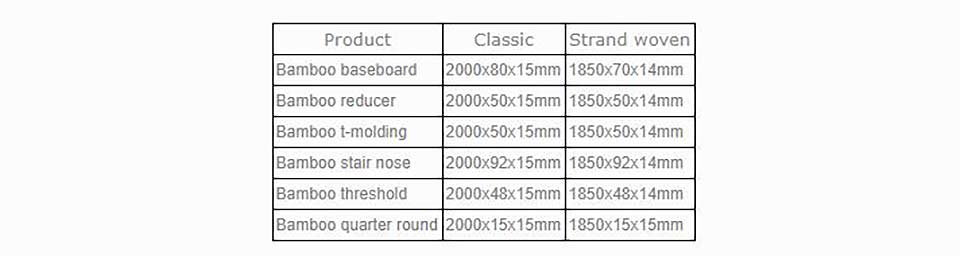

Stair slab

Stair slab

| Characteristic | Value | Test |

| Density: | +/- 1030 kg/m3 | EN 14342:2005 + A1:2008 |

| Brinell hardness: | 9.5 kg/mm² | EN-1534:2010 |

| Moisture content: | 8.3 % at 23°C and 50% relative humidity | EN-1534:2010 |

| Emission class: | Class E1 (LT 0,124 mg/m3, EN 717-1) | EN 717-1 |

| Differential swelling: | 0.17% pro 1% change in moisture content | EN 14341:2005 |

| Abrasion resistance: | 16’000 turns | EN-14354 (12/16) |

| Compressability: | 2930 kN/cm2 | EN-ISO 2409 |

| Impact resistance: | 6 mm | EN-14354 |

| Fire properties: | Class Cfl-s1 (EN 13501-1) | EN 13501-1 |