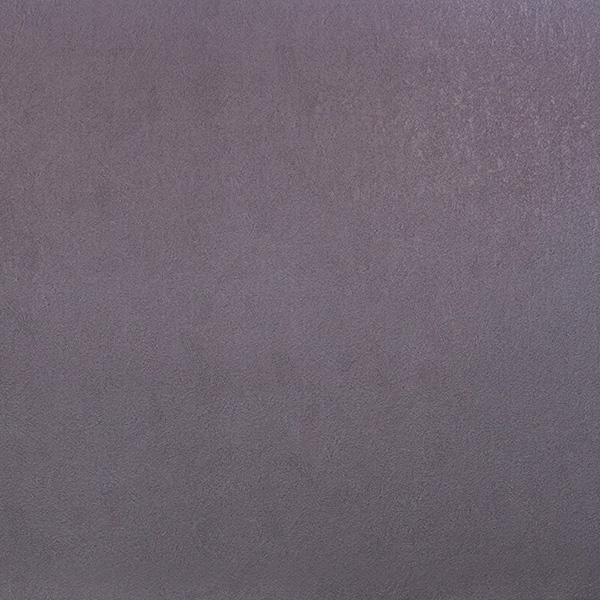

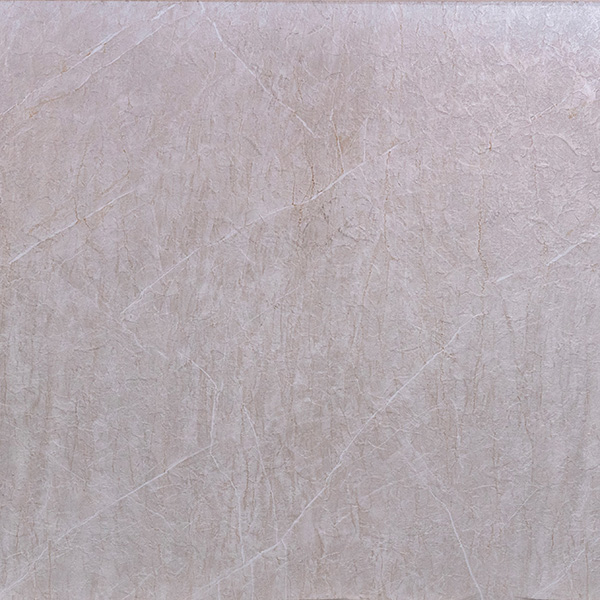

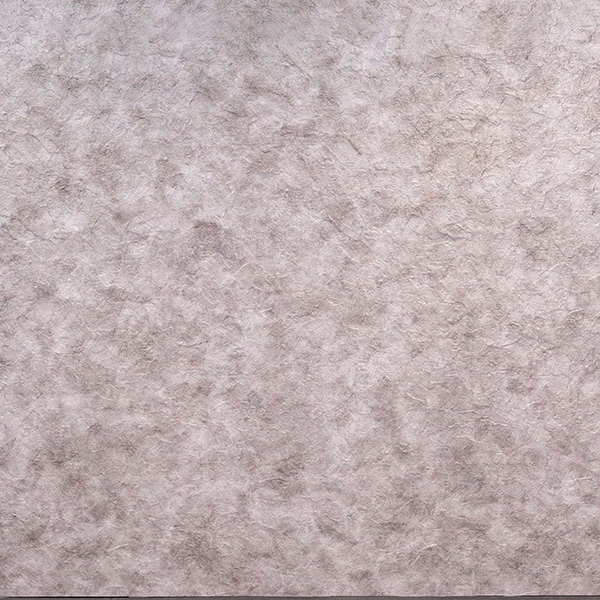

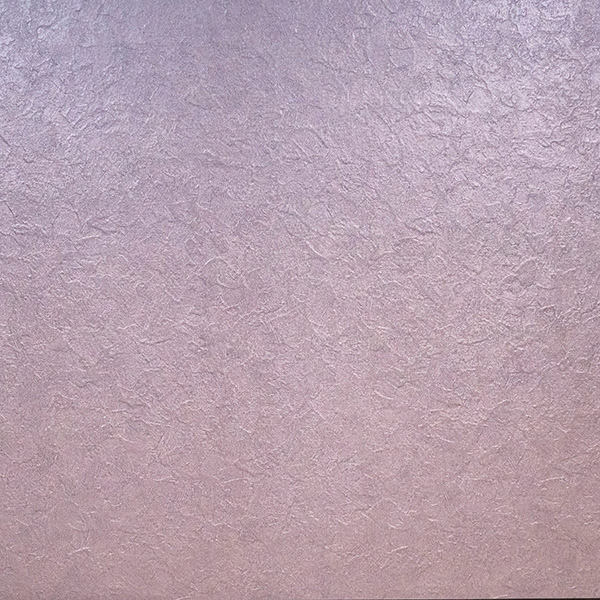

Interior Wpc Wall Panel and UV Glossy SPC Sheet Effect picture for Background Wall

What is PVC wall cladding paneling sheets advantage ?

PVC wall cladding paneling sheets is a high-quality new wall decoration material. It is made of polymer pvc and marble powder. It is a new high-tech material in the 21st century.

It uses natural marble powder to form a high-density solid base layer with a fiber network structure covered with various wood and stone color wall cladding films, which are processed by extrusion molding, filming, painting, packaging and other processes. Since its birth, stone-plastic wall panels have had a huge impact on the decoration material industry.

What are the advantages?

1. Green

The material is natural calcium powder without radioactive elements.

2. Resistance to friction, acid and alkali, and corrosion

Since the surface is a pvc wall color film, all have excellent chemical properties.

3. High elasticity and super impact resistance

It has good elasticity and can recover well under the impact of heavy objects.

4. Waterproof and moisture-proof

As long as it is not immersed in water for a long time, it will not be damaged and will not be moldy due to changes in humidity. It has good waterproof and moisture-proof performance.

5. Sound absorption and noise reduction

The wall panel has a good sound absorption effect, and the attraction rate can reach 20 decibels. It is very suitable for places that require quietness, and provides consumers with a more comfortable and humanized living environment.

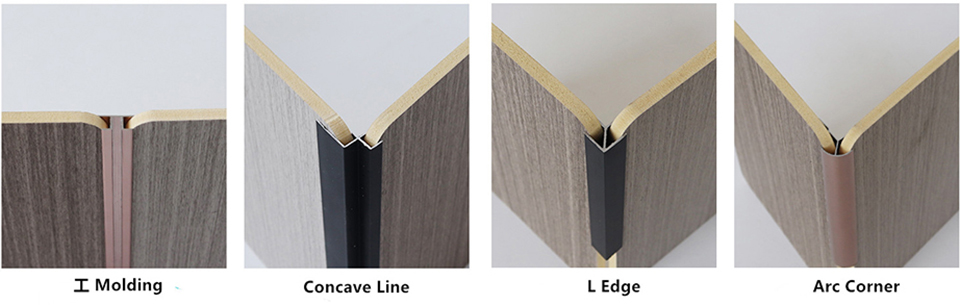

6. Small seams and seamless stitching

Since the splicing seam is very small, it is used with metal lines, and the overall effect and visual effect are very good, which is very suitable for commercial use and home decoration.

7. Fast installation and construction

wall cladding paneling installation does not require cement mortar, just use glue to paste, it can be used after 24 hours.

8. Various colors

The paneling sheets has various colors and can also be customized according to the needs. The texture is realistic and beautiful.

9. Heat conduction and warmth

It has good thermal conductivity and the heat dissipation performance is relatively uniform and stable.

Multiple Colors

Size

Detail Image

Specification

| Dimension | Name | UV SPC SHEET or SPC SINTERED STONE |

| Material | 42%PVC resin+55%Calcium+3%Additive Composite | |

| Size | 4X8FT (1220*2440mm) | |

| Thickness | 1.5mm/2.0mm/2.5mm/2.7mm/3.0mm/3.5mm/4.0mm/5.0mm/6.0mm | |

| Designs | More than 500 designs(custom made designs by 3D print) | |

| Technology | Extrusion Plate+Hot stamping Film+UV coating | |

| Function | Type | Wall & Furniture cabinet&Ceiling PVC marble sheet |

| Feature | Waterproof; Fireproof; Moisture-proof; | |

| Advantage | Bendable; Wear-resisting; Sunscreen | |

| Application | Furniture cabinet, interior wall decoration such asrestaurant, hotel, supermarket, kitchen, living roomand so on. | |

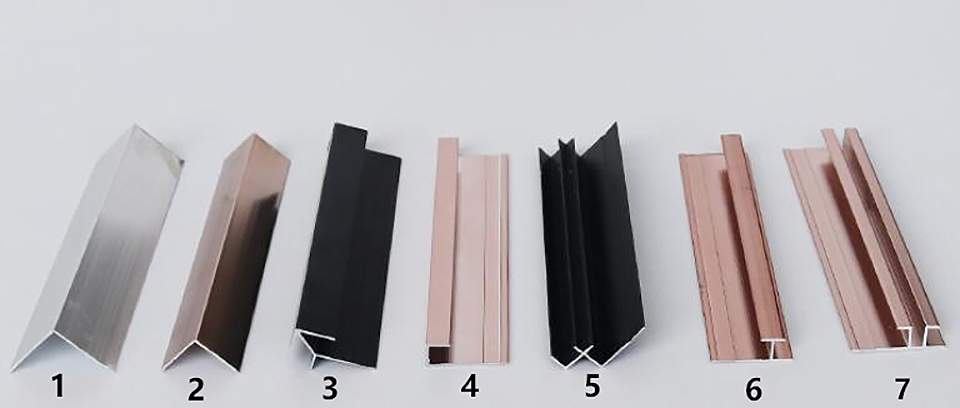

| Installation | 1.Glue on the furniture cabinet or wall,2.Aluminum trim profile 3. Sealant installation |

|

| Service | Certification | ISO9001, CE, SGS |

| Sample | Free samples available | |

| Min Order | 100 PCS | |

| Packing | Wooden pallet + corner protection + metal strap. | |

| Delivery Time | Shipped in 5-15 days after payment |

Package list

| Common Thickness For Reference | ||||

| Thickness(mm) | Tolerance (mm) | Weight(kg/pc) | Tolerance(kg) | MOQ(20GP/pcs) |

| 1.3mm | +-0.05 | 8.0kg/pc | +-0.5 | 3000pcs |

| 1.5mm | +-0.05 | 8.2kg/pc | +-0.5 | 2700pcs |

| 2.0mm | +-0.05 | 12.3kg/pc | +-0.5 | 2000pcs |

| 2.5mm | +-0.05 | 15.3kg/pc | +-0.5 | 1600pcs |

| 2.8mm | +-0.05 | 17.2kg/pc | +-0.5 | 1400pcs |

| 3.0mm | +-0.05 | 18.4kg/pc | +-0.5 | 1300pcs |

| 3.2mm | +-0.05 | 19.6kg/pc | +-0.5 | 1250pcs |

| 3.5mm | +-0.05 | 21.5kg/pc | +-0.5 | 1150pcs |

| 4.0mm | +-0.05 | 24.5kg/pc | +-0.5 | 1000pcs |

| 5.0mm | +-0.05 | 30.7kg/pc | +-0.5 | 800pcs |

| 6.0mm | +-0.05 | 36.8kg/pc | +-0.5 | 650pcs |

Advantage

A. 100% Waterproof

B. Environmental friendly

C. Fire prevention

Production Process

1.Raw materials: resin, calcium powder, stabilizer, etc.

2.After mixing and extruding raw materials, the Spc wall sheet is formed in one piece

3.Uv treatment, surface gloss adjustment, it will be like marble finish

4.Packing and Palletizing

Applications

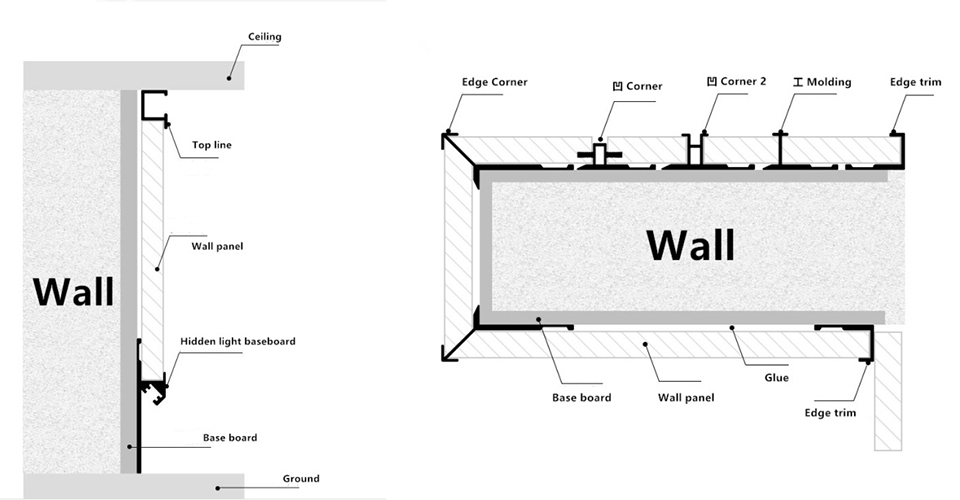

Installation diagram:

Installation diagram:

Installation tips:

Installation tips:

First fix the aluminum decorative line on the wall or base board with steel nails or self-tapping screws, install the decorative panel, and fix it with glue on the back

Installation example:

Installation example:

| Characteristic | Test Specification and Result |

| Squareness | ASTM F2055 – Passes – 0.020 in. max |

| Size and Tolerance | ASTM F2055 – Passes – +0.015 in per linear foot |

| Thickness | ASTM F386 – Passes – Nominal +0.006 in. |

| Flexibility | ASTM F137 – Passes – ≤1.1 in., no cracks or breaks |

| Dimensional Stability | ASTM F2199 – Passes – ≤ 0.025 in. per linear foot |

| Heavy Metal Presence / Absence | EN 71-3 C — Meets Spec. (Lead, Antimony, Arsenic, Barium, Cadmium, Chromium, Mercury and Selenium). |

| Smoke Generation Resistance | EN ISO 9239-1 (Critical Flux) Results 9.2 |

| Smoke Generation Resistance, Non-Flaming Mode | EN ISO |

| Flammability | ASTM E648- Class 1 Rating |

| Residual Indentation | ASTM F1914 – Passes – Average less than 8% |

| Static Load Limit | ASTM-F-970 Passes 1000psi |

| Requirements for Wear Group pr | EN 660-1 Thickness Loss 0.30<I<0.60 prEN 660-2 Volume Los 7.6<F <15.0 |

| Slip Resistance | ASTM D2047 – Passes – > 0.6 Wet, 0.6 Dry |

| Resistance to Light | ASTM F1515 – Passes – ∧E ≤ 9 |

| Resistance to Heat | ASTM F1514 – Passes – ∧E ≤ 9 |

| Electrical Behavior (ESD) | EN 1815: 1997 2,0 kV when tested at 23 C+1 C |

| Underfloor Heating | Suitable for installing over under floor heating. |

| Curling After Exposure to Heat | EN 434 < 1.8mm pass |

| Recycled Vinyl Content | Approximately 40% |

| Recyclability | Can be recycled |

| Product Warranty | 10-Year Commercial & 15-Year Residential |

| Floorscore Certified | Certificate Provided Upon Request |