Phapano ke efe lipakeng tsa Co-Extrusion le Common Extrusion Wpc Wallpanel?

1. Theknoloji e tsoetseng pele ea co-extrusion

Ka theknoloji e tsoetseng pele ea phekolo ea holim'a metsi, bokaholimo bo na le moelelo o matla oa lehong le tiileng.Moloko oa bobeli o phethahetseng oa tšireletso o fetelletseng o tla rarolla ka botlalo mathata a Tloaelehileng Extrusion, joalo ka: ho senyeha, ho chalking, ho putlama, hlobo, matheba le ho phatloha.

2. Ts'ebetso e ntle ea qulity

1. Anti-ho kenella

√Bokaholimo bo koahetsoe ka lipolasetiki tsa boenjiniere tse tsoetseng pele

√360-letlapa le felletseng la ho roala

√Ho monya metsi a tlase haholo, <0.2%

√ Veine, kofi, sauce, oli ea bohlokoa ha e khone ho kenella ka har'a boto

2. Ha ho ho fela

Ha ho bapisoa le lebota le tloaelehileng la extrusion, thepa e ikhethang ea ho roala holim'a metsi ea moloko oa bobeli oa lehong la polasetiki le kopantsoeng le kopantsoe le lisebelisoa tse khahlanong le UV, 'me' mala oa boto o tšoarella haholoanyane.Teko ea UV ea lihora tse 3500 e bonts'a hore ho potlaka ha 'mala oa lehong le kopaneng ho ka ba 3.8, e tlase ho feta phetoho ea' mala e ka bonoang ka mahlo.

3. Anti-mold le anti-cracking, bophelo bo bolelele ba tšebeletso

Thepa e tsoetseng pele ea ho roala holim'a metsi e etsa bonnete ba hore ha ho na metsi a kenang linthong, 'me sehlahisoa se lumelisa mathata a tšoenyang a kang hlobo le ho phunyeha,' me se fumana bophelo bo bolelele.

4. E manganga lehetleng

Bokaholimo ba sehlahisoa bo sebelisa lipolasetiki tsa boenjiniere tse tsoetseng pele ho etsa bonnete ba hore sehlahisoa se na le khanyetso e matla ea mongoao

5. Ho bonolo ho hloekisa, litšenyehelo tse tlaase tsa tlhokomelo

Ka lebaka la ho roala holim'a sehlahisoa le theknoloji e tsoetseng pele ea anti-permeation, matheba a khomaretsoeng holim'a sehlahisoa a ka hlakoloa habonolo, a etsa hore ho hloekisa le ho lokisoe habonolo.Tlohela ho penta le ho tlotsa boka kamehla, ho boloka nako le chelete.

Lintlha Litšoantšo

Pontšo ea Mmala

Nako e telele ea ho phela

Tlhokomelo e tlase

Ha ho Warping kapa Splintering

Libaka tsa ho tsamaea tse hananang le ho thella

Ha e Khethe

E hanyetsanang le Letheba

Ha e kenele metsi

Waranti ea lilemo tse 15

95% ea patsi le polasetiki e sebelisitsoeng hape

Anti-microbial

Mollo Mohatelli

Kenyelletso e Bonolo

Paramethara

| Brand | DEGE |

| Lebitso | Sebaka sa marang-rang sa Wpc |

| Ntho | Tloaelehileng Extrusion |

| Boholo bo tloaelehileng | 2900*205*20mm |

| Karolo ea WPC | 30% HDPE + 60% fiber ea lehong + 10% li-additives |

| Lisebelisoa | Sistimi e bonolo ea patent ea clip |

| Nako ea thomello | Hoo e ka bang matsatsi a 20-25 bakeng sa setshelo se le seng sa 20'ft |

| Tefo | 30% e kentsoe, e setseng e lokela ho lefuoa pele e tlisoa |

| Tlhokomelo | Tlhokomelo ea mahala |

| Recycling | 100% e ka sebelisoa hape |

| Sephutheloana | Paletla kapa ho paka ka bongata |

Sebaka se Fumanehang

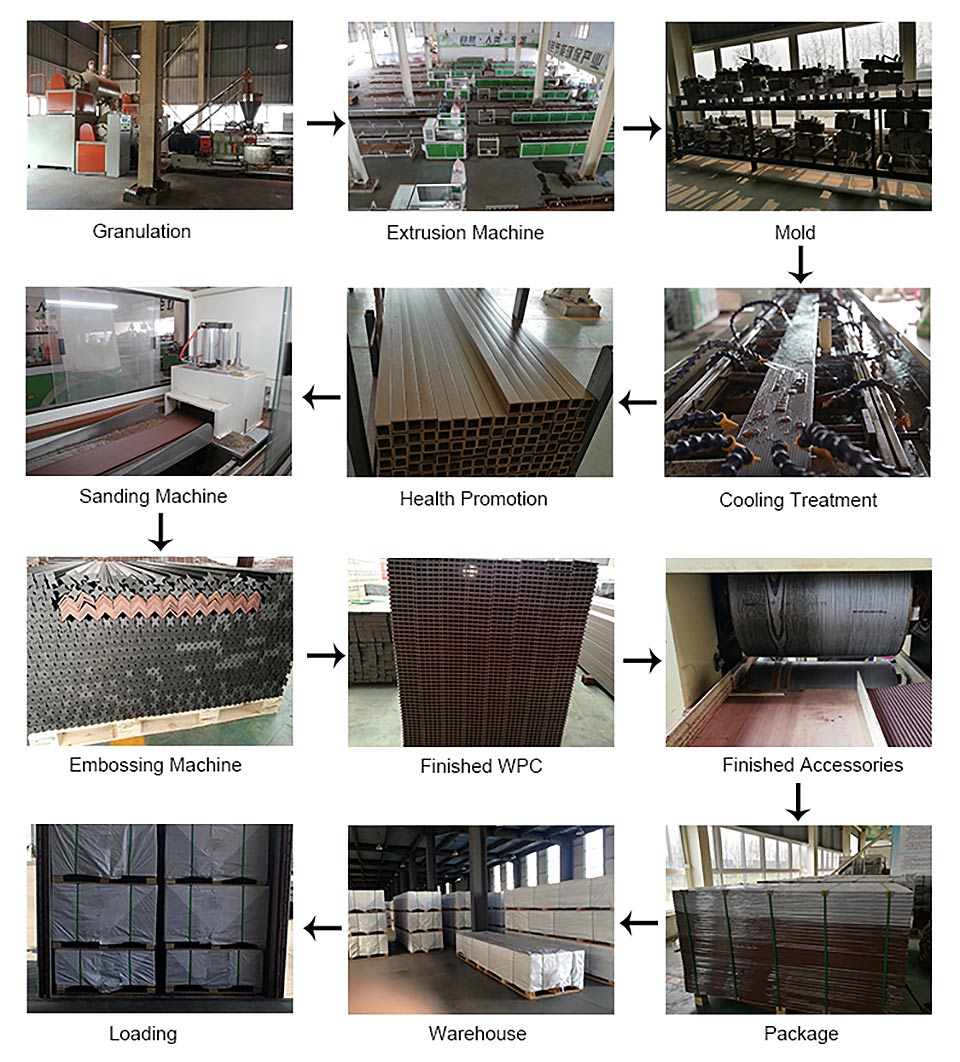

Wpc Wall Panel Production Process

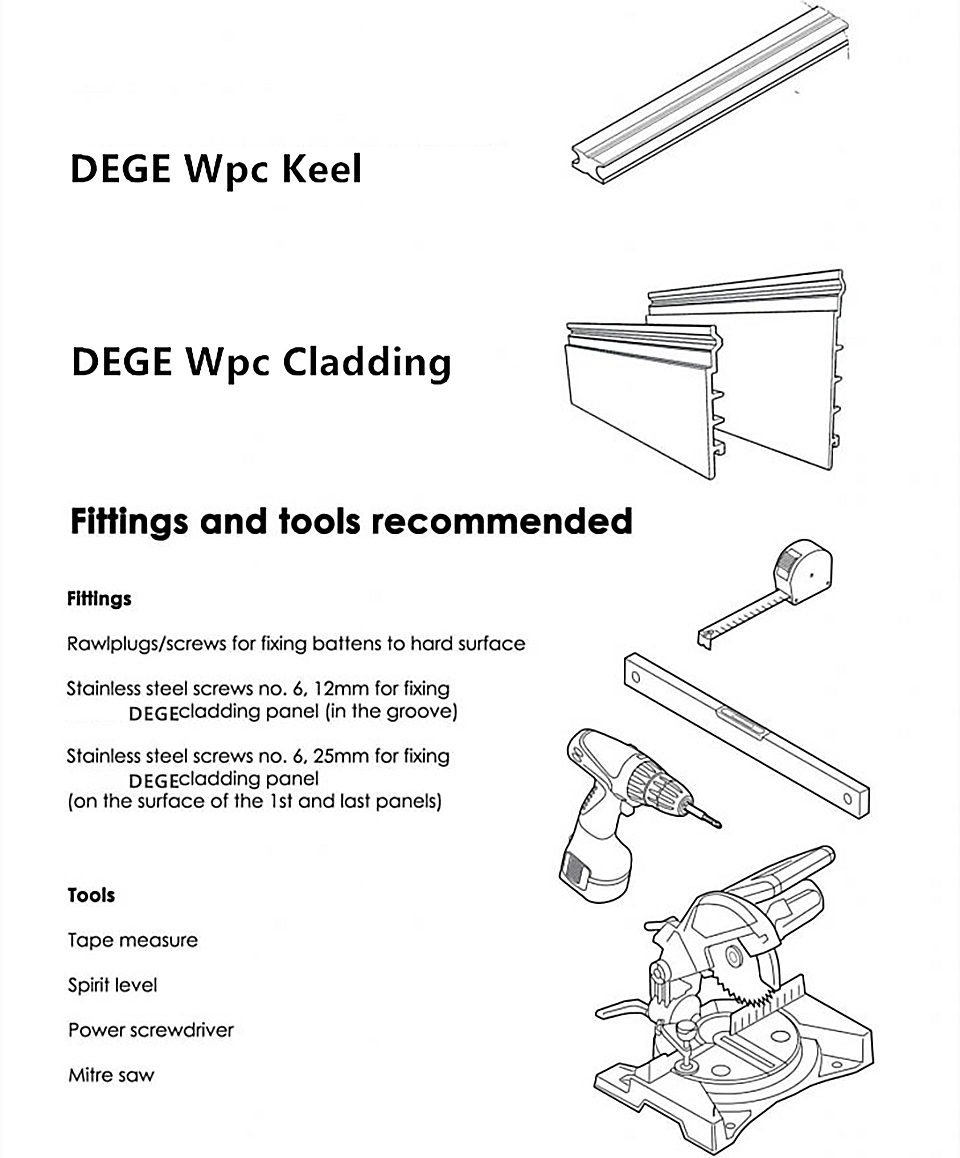

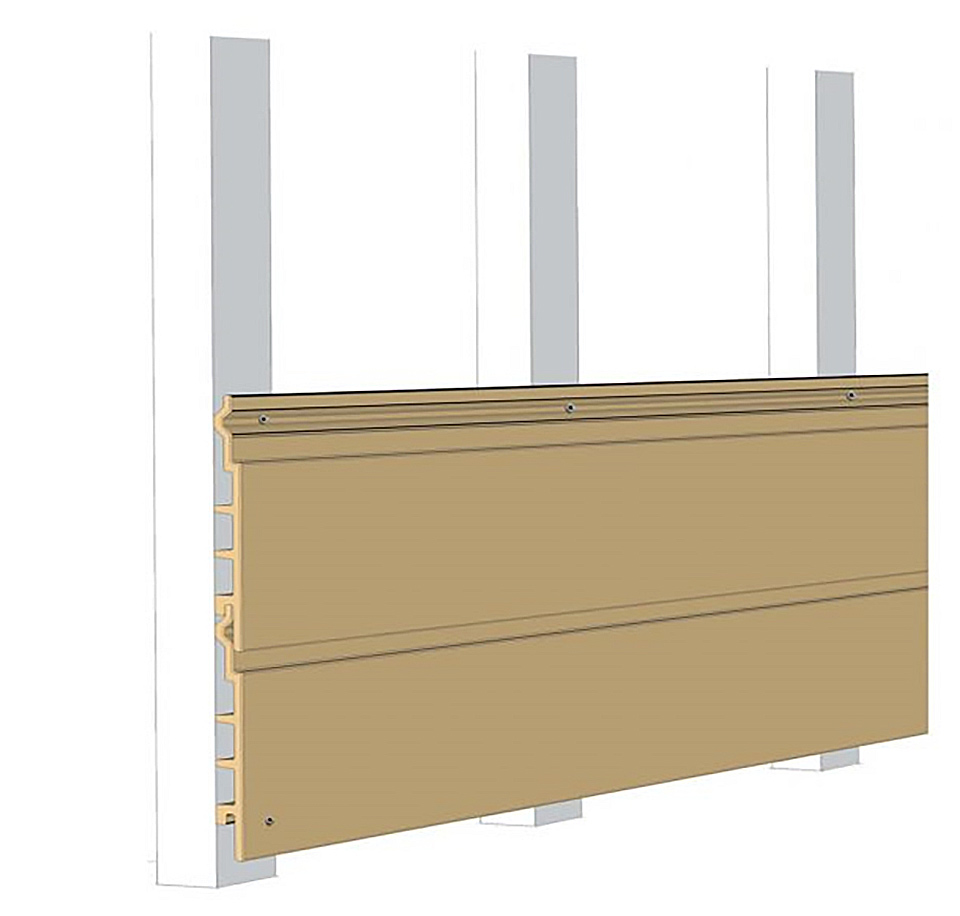

Sephutheloana sa Wallpanel sa Wpc le Lintlha tse Tlang

Kopo

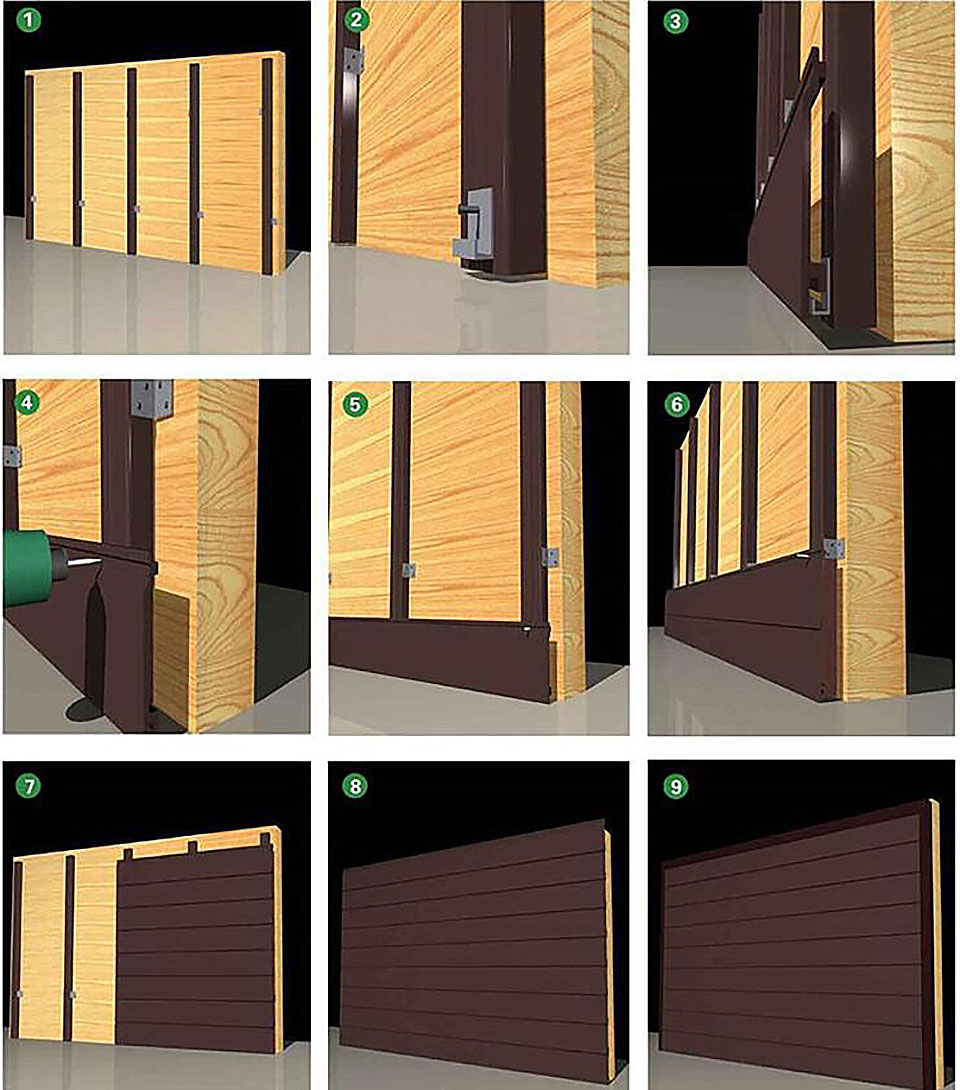

1. Kenya keel pele

2. Metal buckle e kenngoa ka tlaase ho keel

3. Letlapa le ka tlase la lerako le khomaretsoe holim'a tšepe ea tšepe

4. Lokisa phanele ea lebota ho keel ka lipekere

5. Letlapa lohle la lebota le hloka lipekere hore li behoe holim'a keel

6. Kenya lebota la bobeli leboteng la pele, 'me u phete mehato ea 4 le ea 5

7. Thepa ea pele e emeng

8. Ea bobeli paatsepama tlhomamiso

9. Eketsa banding ea bohale

| Botenya | 1.35g/m3 (E Tloaelehileng: ASTM D792-13 Mokhoa oa B) |

| Matla a tšepe | 23.2 MPa (E Tloaelehileng: ASTM D638-14) |

| Matla a flexural | 26.5Mp (E Tloaelehileng: ASTM D790-10) |

| Flexural Modulus | 32.5Mp (E Tloaelehileng: ASTM D790-10) |

| Matla a tshusumetso | 68J/m (Tlwaelelo: ASTM D4812-11) |

| Bothata ba lebopo | D68 (E Tloaelehileng: ASTM D2240-05) |

| Ho monya metsi | 0.65% (E Tloaelehileng: ASTM D570-98) |

| Katoloso ea mocheso | 42.12 x10-6 (E tloaelehileng: ASTM D696 – 08) |

| Ha e thellehe | R11 (E tloaelehileng: DIN 51130:2014) |

Morero

Morero