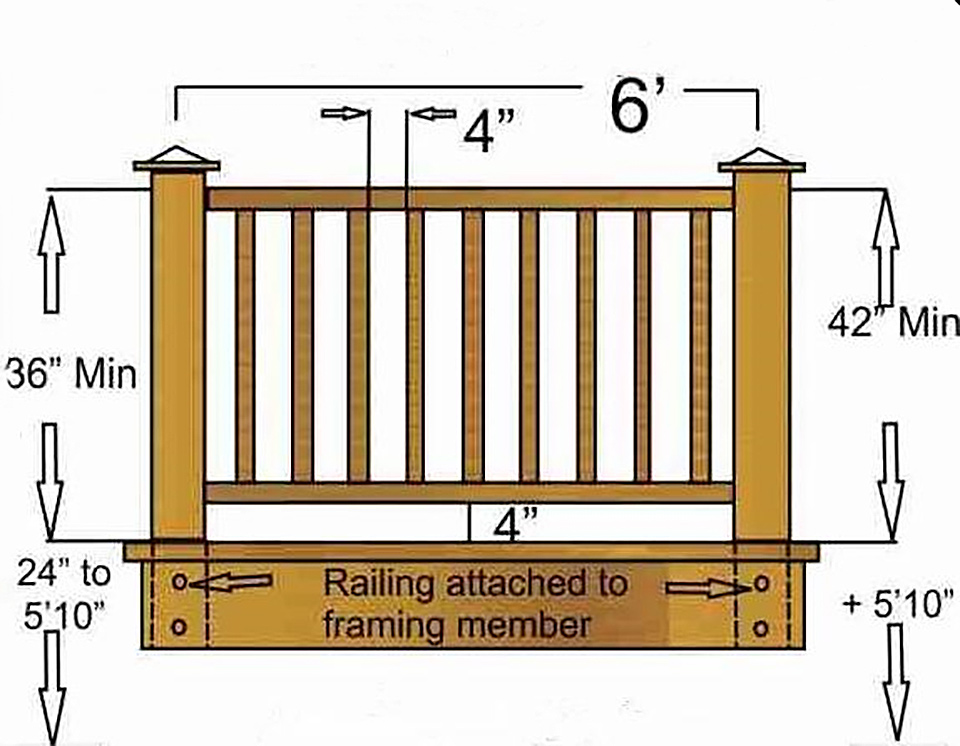

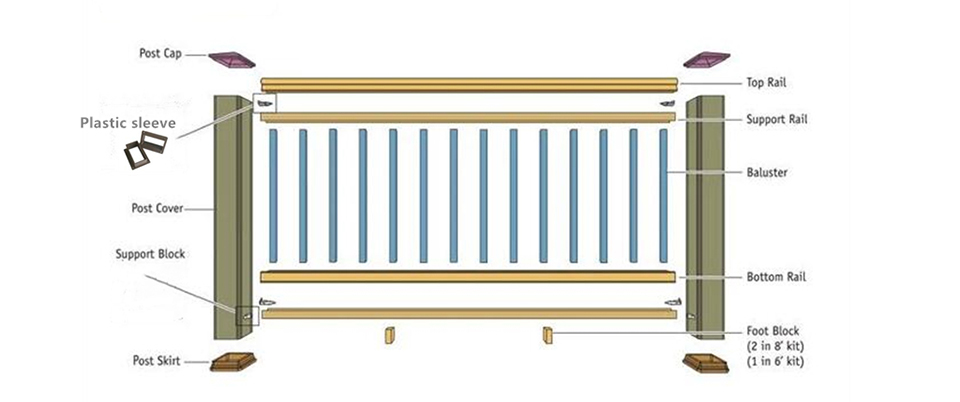

Faahfaahinta Sawirada

WPC Baluster

WPC Baluster

WPC Baluster

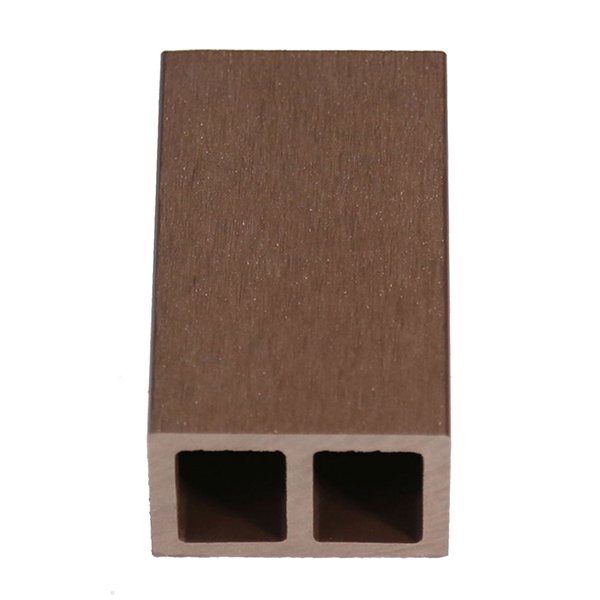

WPC Boostada Sleeve

WPC Boostada Sleeve

Tareenka ugu sarreeya ee WPC & Tareenka Hoose

Tareenka ugu sarreeya ee WPC & Tareenka Hoose

WPC Boostada Sleeve

Muujinta Midabka

Cimri dheer

Dayactirka hooseeya

Kabid iyo kabid ma jiro

Sagxadaha socda ee u adkaysta simbiriirixiinta

Iska caabbinta xoqitaanka

Iska caabinta wasakhda

Biyo ma galeen

15 Sano Garanti

95% alwaax iyo baco dib loo warshadeeyay

Anti-microbial

Dab-iska-caabbinta

Rakibaadda fudud

Halbeegga

| Summada | DEGE |

| Midabada | Cawl khafiif ah, Beige, Orange, Brown, Shaah qoto dheer, cawl qoto dheer |

| Magaca | |

| Shayga | |

| Cabbirka caadiga ah (Balac * Dhererka) | |

| Dhererka | 2.2m,2.9m,5.6m ama la habeeyey |

| Qaybta WPC | 35% HDPE + 60% fiber alwaax + 5% wax lagu daro |

| Agabka | Nidaam fudud oo-clip-fudud oo bateysan |

| Waqtiga dirida | Qiyaastii 15-20 maalmood hal 20'ctn |

| Lacag bixinta | 30% la dhigay, inta soo hartay waa in la bixiyaa ka hor inta aan la keenin |

| Codsiga | Sagxadda, sagxadda dhulka, qashinka, deyrka, darbiga, sanduuqa ubaxa, iwm |

| Wpc Hs Code | 39189090 |

| Xidhmada | Baakad ama baakad badan |

| dammaanad | 10 Sano |

| Astaamaha ugu muhiimsan: | 1. La wareegi karo, deegaan-saaxiibtinimo, kaydinta khayraadka kaynta 2. Iyadoo muuqaalka dhirta dabiiciga ah, laakiin dhibaatooyinka alwaax yar 3. Qoyaanka/biyaha u adkaysta, qudhun yar, oo lagu caddeeyey xaalad biyo milix ah 4. Saaxiibtinimada kabo-la'aan, simbiriirixidda, dildilaac yar, dagaal yaraan 5. Uma baahna rinjiyeyn, ma laha koollo, dadaal yar oo dayactir ah 6. Cimilada u adkaysata, ku haboon laga jaray -40 ilaa 60 digrii, anti-UV 7. Cayayaanka u adkaysta, caaryadana u adkaysta 8. Si fudud loo rakibo oo loo nadiifiyo 9. model kala duwan sida looga baahan yahay |

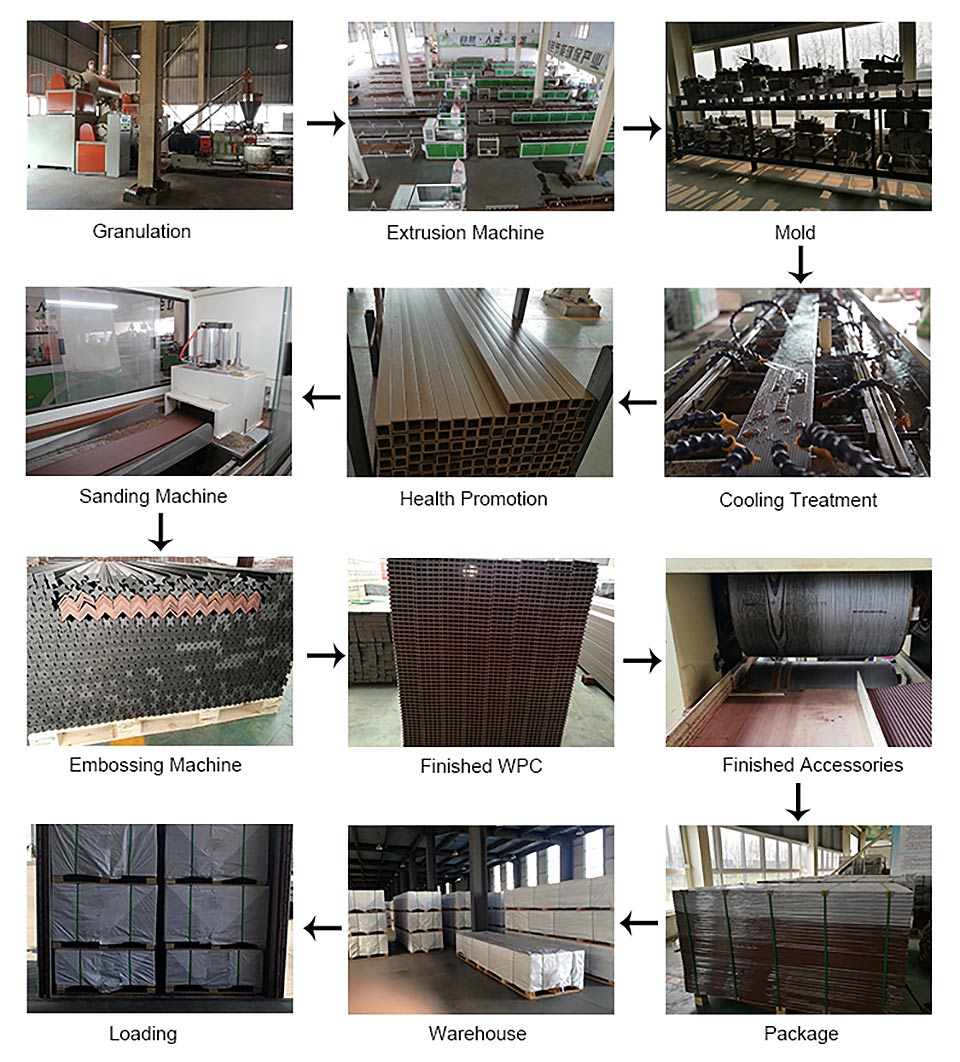

Habka Wax-soo-saarka Gudigga gidaarka ee Wpc

A. PE alwaax caag ah waa nooca loogu isticmaalka badan yahay alwaax caag ah adduunka, taas oo ah, our WPC CLADING, WPC deyrka.Ugu horreyntii, aynu fahamno alaabta ceeriin ee alaabta alwaax caag ah ee PE.Alaabta ceeriin ee ugu muhiimsan waa balaastiigga PE iyo budada geed poplar., Toner, nuuga ka-hortagga ultraviolet, compatibilizer.

1. Balaastigga PE: Isbarbardhigga guud ee qiimaha iyo isku dhafka HDPE ayaa ah doorashada ugu fiican, iyo alwaax caag ah oo suuqa ku jira ayaa asal ahaan isticmaala agabka dib loo warshadeeyay oo ah alaabta ceeriin ee ugu weyn, taas oo yaraynaysa wasakhowga cad oo ka dhigaya deegaankeena mid caafimaad qaba iyo deegaan saaxiibtinimo leh."Dib-u-warshadaynta" waxa kale oo loo yaqaannaa walxo caag ah oo dib loo warshadeeyey.Dhammaan caagadaha dib loo warshadayn karo ee dib loo isticmaali karo iyada oo loo marayo hab habaysan ayaa loo yaqaan balaastiig dib loo warshadeeyey;Agabka dib loo warshadeeyay waxa loo qaybiyaa darajooyin badan, sida agab dib loo warshadeeyay oo fasal gaar ah iyo kuwa fasalka kowaad dib loo warshadeeyay., Dib-u-warshadaynta labaad, dib-u-warshadaynta jaamacadeed ama xitaa qashinka, way fududahay in la fahmo macnaha macno ahaan, heerka sare ee darajada, yaraanta maadada wasakhda ah ee caaga ah, qashinka ayaa si dabiici ah ugu sarreeya nuxurka wasakhda, iyo xulashada alaabta ceeriin si toos ah Waxay saamaysaa doorashada alwaax caag ah Sababtoo ah walxaha balaastigga ah waa xaalad meesha budada alwaax lagu duudduubay caag, haddii maadada wasakhda ah ee caagga ah ay sarreeyso, iyo saamiga balaastigga laftiisa waa yar yahay, dabiiciyan ma awoodo inay si fiican u duubto budada alwaax .

2. Daqiiqda alwaax: Si loo gaaro isku-dhafka ugu fiican ee burka alwaax iyo caag ah ee alwaax caag ah, ma jiraan shuruudo adag oo kaliya oo ku saabsan balaastigga, laakiin sidoo kale burka alwaax: burka alwaaxda ee miisaanka la mid ah, ayaa weynaanta aagga dusha sare. ee budada.Inta badan saamiga balaastikada ee loo baahan yahay;liddi ku ah, weynaanta budada budada ah ee alwaax, ayaa sii yaraanaya aagga dusha sare ee budada, iyo hoos u dhigista saamiga caagga ah ee loo baahan yahay inta lagu jiro isku-dhafka caagga ah.Ka dib sanado badan oo tijaabo ah, budada alwaax budada ah ayaa ah budada budada alwaax ugu fiican, xajmiga qaybta budada ayaa ugu fiican dhumucda 80-100 mesh;budada waa mid aad u fiican, kharashka farsamaynta ayaa sarreeya, halabuurka caaggu wuxuu u baahan yahay wax badan, kharashkuna wuu sarreeyaa, laakiin alaabta caagga ah ee la qaabeeyey ayaa leh caag aad u sarreeya;haddii budada ay aad u qallafsan tahay, kharashka farsamayntu waa yar yahay, shuruudaha halabuurka caagguna waa yar yahay, laakiin alaabta caagga ah ee la qaabeeyey ayaa leh fiyuus ku filan, waa jajaban yahay, waana sahlan tahay in la dillaaco.

3. Walxaha caawinta: Shaqada ugu weyn ee toner waa in la isku daro midabka alaabta alwaaxda.Waqtigan xaadirka ah, codsiga ugu weyn ee alwaax caag ah PE waa budada midabka aan organic ahayn.Waxay leedahay waxqabadka ka-hortagga ka-hortagga ka-hortagga isticmaalka dibadda, taas oo ka duwan midabka dabiiciga ah ee loo isticmaalo qoryaha deegaanka ee gudaha ee PVC.Budada, midabka toner organic waa mid aad u muuqda oo dhalaalaya.Shaqada ugu weyn ee nuugista ka-hortagga ultraviolet waa in la hagaajiyo awoodda ka-hortagga ultraviolet ee alwaax caag ah oo bannaanka loo isticmaalo, iyo hagaajinta waxqabadka gabowga.Compatibilizer waa wax lagu daro ah oo kor u qaada iswaafajinta ka dhexeeya daqiiqda iyo xabagta.

B. Si kooban u fahan alaabta ceeriin ee alwaax caag ah, tillaabada xigta waa in la jeexjeexo.Marka loo eego alaabta ceeriin ee kor ku xusan, isku qas si waafaqsan saamiyo gaar ah, ka bixi pellets alwaax caag ah iyada oo loo marayo qalajinta fiyuuska heerkulka sare, oo u xir si aad u isticmaasho.Shaqada ugu weyn ee qalabka pelletizing waa in la xaqiijiyo habka pre-plasticization ee budada alwaax iyo balaastig ah, la ogaado isku-dhafka isku midka ah ee walxaha budada biomass iyo balaastikada PE ee xaaladaha dhalaalidda, iyo in la sameeyo pretreatment ee soo saarista alaabta alwaax caag ah.Sababtoo ah dareeraha liidata ee dhalaalka alwaax-caag ah, naqshadaynta alwaax-caag alwaax ah pelletizer alwaax iyo pelletizer caag ah maaha mid isku mid ah.Balaastikada kala duwan, naqshadeynta pelletizer sidoo kale waa ka duwan tahay.Pelletizer-ka sida caadiga ah loo isticmaalo polyetylen-ka inta badan waxa uu isticmaalaa dabaylaha mataanaha ah ee koonka ah, sababtoo ah polyetylenku waa xabagta kulaylka leh, dabaylaha mataanaha ah ee conical-ka ah ayaa leh awood xiirid oo xoog leh dhererka daboolkuna waa siman yahay.Extruder fur mataano ah waa gaaban yahay, taas oo yaraynaysa waqtiga joogitaanka ee walxaha ku jira foosto.Dhexroorka dibadda ee furku wuxuu leeyahay naqshad conical ka weyn ilaa yar, sidaas darteed saamiga cadaadisku waa mid aad u weyn, walxahana waxaa lagu dhejin karaa si buuxda oo isku mid ah foosto.

C. Ka dib pelleting, waxay gashaa heerka extrusion.Dhowr diyaargarow ayaa loo baahan yahay in la sameeyo ka hor inta aan la saarin:

1. Hubi in aysan jirin wax wasakh ah ama qaybo ka mid ah midabada kale ee ku haray hopper si looga fogaado midab aan nadiif ahayn oo alwaax caag ah oo la soo saaray;

2. Hubi in qalabka faakuumka ee fuqaha uu yahay mid aan xannibnayn oo hubi in heerka faakuumku aanu ka yarayn -0.08mpa.Foostada faakuumka waa in la nadiifiyaa laba jeer maalintiiba haddii ay caadi tahay.Ha isticmaalin qalabka birta ah si aad u nadiifiso godadka qiiqa, isticmaal bac ama ulo alwaax ah si aad u nadiifiso wasakhda ku jirta godadka qiiqa ee foosto;

3. Hubi in hopper ku qalabaysan yahay shaandhada birta ah iyo in kale.Qaybaha waxaa lagu sifeeyaa biraha si looga saaro wasakhda birta ah ee isku dhafan ee qaybaha, la yareeyo xirashada wasakhda birta ee gudaha qalabka iyo in la hubiyo isku-dhafka qumman ee profiles caag-qoryo ah.

4. Haddii nidaamka biyaha qaboojintu uu si caadi ah u shaqeeyo.Nidaamka biyaha qaboojinta qumman ayaa ah qalabka lagama maarmaanka u ah qaboojinta ka dib balaastig-alwaax.Daaweynta qaboojinta wakhtiga waxay xaqiijin kartaa qaabka wanaagsan ee caag-qoryaha profiles.

5. Ku rakib caagagga alwaax, oo ku dheji caaryada loo qoondeeyay iyadoo loo eegayo muuqaalada la soo saarayo.

6. Hubi in mishiinka goynta pneumatic-ka iyo qaybaha kale ee daboolku ay si caadi ah u shaqayn karaan.

D. Heerkulka caagga-qoryaha cusub ee la soo saaray aad buu u sarreeyaa, waxaana loo baahan yahay in gacanta lagu dhigo dhul siman.Ka dib markii profile si buuxda loo qaboojiyo, waa la baaraandegi doonaa oo baakadaysan doonaa.Inkasta oo tallaabadani tahay mid fudud, haddana aad bay muhiim u tahay.Haddii warshadu iska indhatirto faahfaahintan, alaabta warshadu waxay inta badan yeelan doontaa cillado.Alwaax caag ah oo aan sinnayn ayaa si fudud u horseedi doona dhumucyo kala duwan ee dusha sare iyo hoose ee alaabta ka dib shiididda iyo habaynta dambe.Intaa waxaa dheer, muuqaalada aan sinnayn waxay keeni doonaan dhibaatooyin qaarkood dhismaha waxayna saameynayaan saameynta muuqaalka.

E. Marka loo eego baahiyaha macaamiisha, ka baaraandegista muuqaalada caagga ah ee alwaax:

1. Daawaynta shiidida waa in meesha laga saaro lakabka maqaarka balaastigga ah ee la soo saaro marka la soo saaro balaastigga alwaax, si balaastigga alwaax uu u yeesho caabbinta caabbinta marka warshadda lagu rakibo.

2. Daaweynta Embossing: Ka dib marka dusha sare ee profile la nadiifiyo, balaastig-alwaax ah ayaa lagu dhejiyaa si loo sameeyo dusha sare ee caag-alwaax leh saameyn alwaax ah.

3. Goynta, farsamaynta farsamada, cabbirka la habeeyey iyadoo loo eegayo baahiyaha macmiilka, iyo alaabada la habeeyey sida baahiyaha kiraysashada.

4. Ka dib marka habka kor ku xusan la dhammeeyo, tallaabada ugu dambeysa waa in la xidho alaabta.Baakadaha macquulka ah ee alaabtu waxay yarayn kartaa waxyeelada ay keento alaabada inta lagu jiro dhalmada.

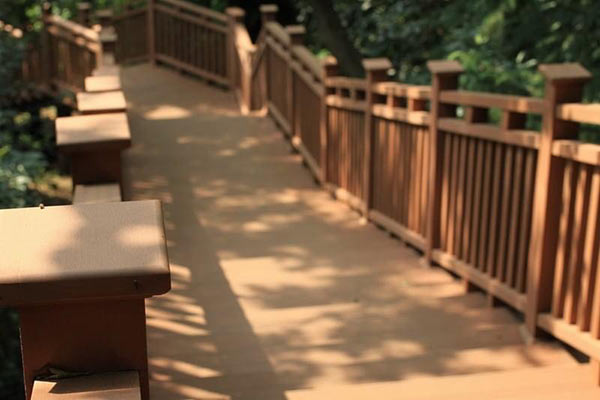

Kiis Injineernimo

| Cufnaanta | 1.35g/m3 (Heerka: ASTM D792-13 Habka B) |

| Xoog xajin | 23.2 MPa (Heerka: ASTM D638-14) |

| Xoog dabacsanaan | 26.5Mp (Heerka: ASTM D790-10) |

| Modulus Flexural | 32.5Mp (Heerka: ASTM D790-10) |

| Awood saamayn | 68J/m (Heerka: ASTM D4812-11) |

| adkaanta xeebta | D68 (Heerka: ASTM D2240-05) |

| nuugista biyaha | 0.65% (Heerka: ASTM D570-98) |

| Balaadhinta kulaylka | 42.12 x10-6 (Heerka: ASTM D696 - 08) |

| U adkaysta simbiriirixidda | R11 (Heerka: DIN 51130:2014) |

Qaabka

Qaabka