Waa maxay Faa'iidada Dabaqa Laminate ee Pine?

1. Ilaalinta deegaanka iyo quruxda.Sagxadaha alwaaxda ee la saaray ayaa deegaanka uga wanaagsan sagxadaha kale, gaar ahaan hadda oo dabaqyo badan oo rinji lagu buufiyay ay leeyihiin heerar aad u sarreeya oo formaldehyde ah.Iyada oo ay ugu wacan tahay dabacsanaanta iyo qulqulka hawada ee sagxadaha alwaaxda, xitaa sagxadaha alwaaxa geedka rinji, waxa ku jira formaldehyde aad ayuu uga hooseeyaa sagxadaha kale.Sagxada alwaax alwaax ah oo aan lahayn buufinta rinjiga waxay haysaa sifooyinka asalka ah, qaabka dabiiciga ah, quruxda dabiiciga ah, iyo wasakh la'aanta.

2. Naqshadayntu waa mid fudud oo casri ah.Qoryaha geedku wuxuu leeyahay hadhuudh cad oo fudud, midabka geedkuna waa mid indhaha ku raaxaysanaya, qaab-dhismeedkuna waa mid aad u fiican, taas oo ah mid ka mid ah sababaha ay u doortaan hab-dhaqameed badan oo jecel.Khasaaraha ay leedahay sagxadda alwaax adag: 1. Sagxadaha alwaaxdu maaha kuwo u adkaysta iftiinka qorraxda, wayna fududahay in la beddelo midabka iftiinka qorraxda.Sababo la xiriira sifooyinka alwaax geedeedka, biyaha sare ee ku jira waa jilicsanaan, ma aha mid adag sida qoryaha kale ee adag, waxayna aad ugu nugul yihiin dildilaaca iyo qallafsanaanta.Alwaax alwaax ah oo aan la rinjiyeynin waa dabiici ahaan fudud, cusub oo qurux badan, laakiin sidoo kale waxay leedahay cillad walaac leh.Haddii dayactirka sagxadda alwaaxa geedka la dayaco, sagxadda alwaaxdu waxay bedeli doontaa midabka ka dib marka ay soo baxdo qorraxda waxayna saameynaysaa quruxdeeda dabiiciga ah, sidaas awgeed pine Laminate Flooring waxay ka fogaanaysaa faa'iido darradan.

Halbeegga

| Midabka | Pine EIR Laminate Flooring | ||

| Dhumucda | 8mm | ||

| Cabbirka | 1218*198mm | ||

| Daaweynta dusha sare | EIR | ||

| Daaweynta cirifka | Rinjiyeynta bevel | ||

| Daawaynta gaarka ah | Logo ku rinjiyeeyay dhabarka,Soundproof EVA/IXPE | ||

| Xiro iska caabin | AC4 heerka EN13329 | ||

| Qalabka salka | HDF cagaaran 850 kg/m³ | ||

| Guji nidaamka | Unilin | ||

| Habka Rakibaadda | Piso sabaynaysa | ||

| Formaldehyde Emission | E1<=1.5mg/L | ||

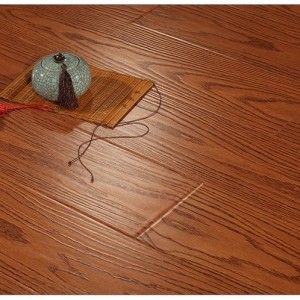

Dusha la heli karo

Dusha Weyn ee Embossed

Dusha sare ee Piano

Dusha gacmaha lagu xardhay

Dusha muraayadda

Dusha EIR

Dusha yar ee Embosed

Dusha Dhabta ah ee Qoryaha

Dusha Crystal

Dusha Dhexe ee Embossed

Guji Nidaamyada La heli karo

Wadajir La Heli karo

Midabada dambe ayaa la heli karaa

Daawooyin Gaar Ah Oo La Heli Karo

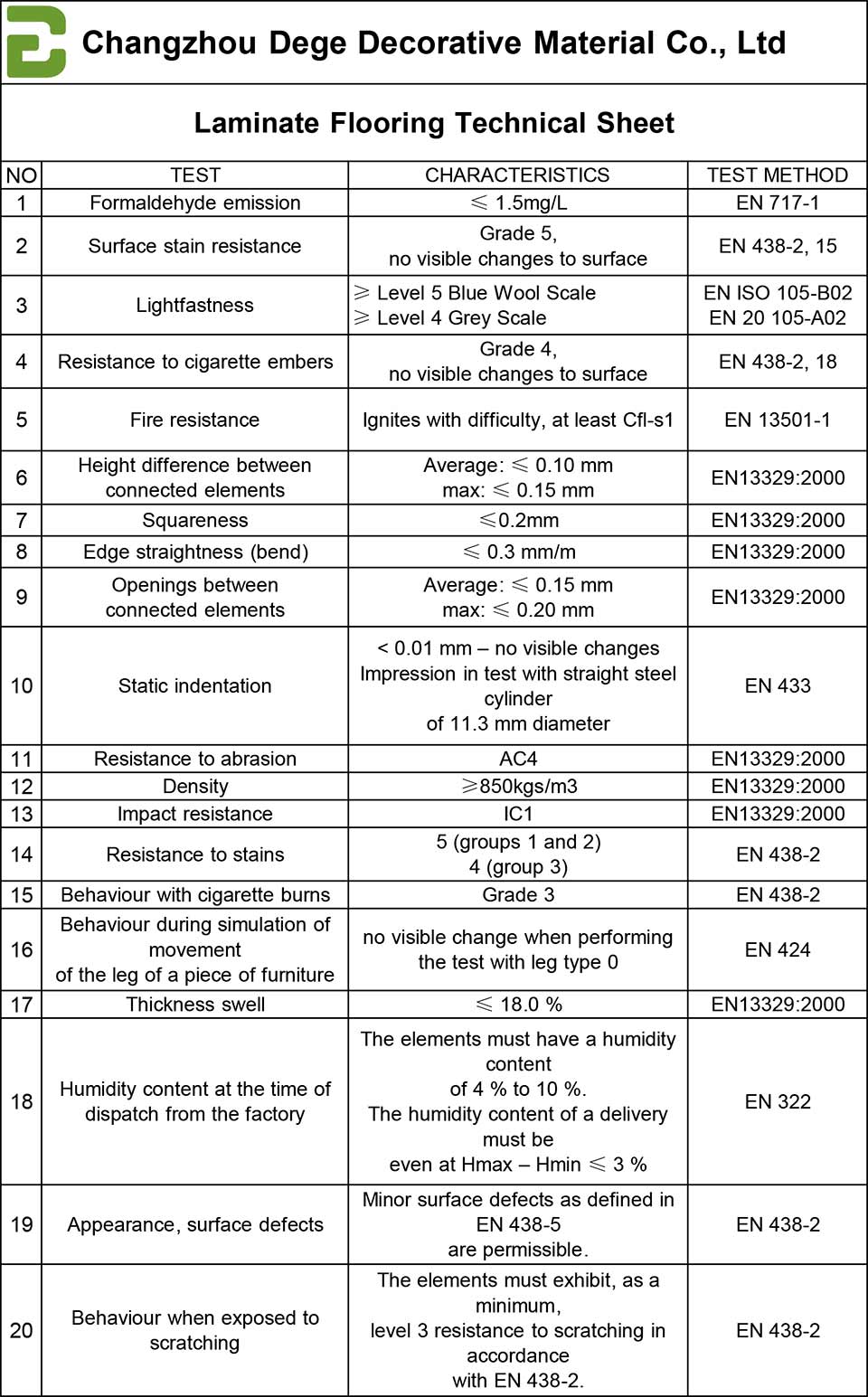

Tijaabada Tayada

Tijaabada mashiinka baaritaanka

Imtixaan dhalaalaya oo sarreeya

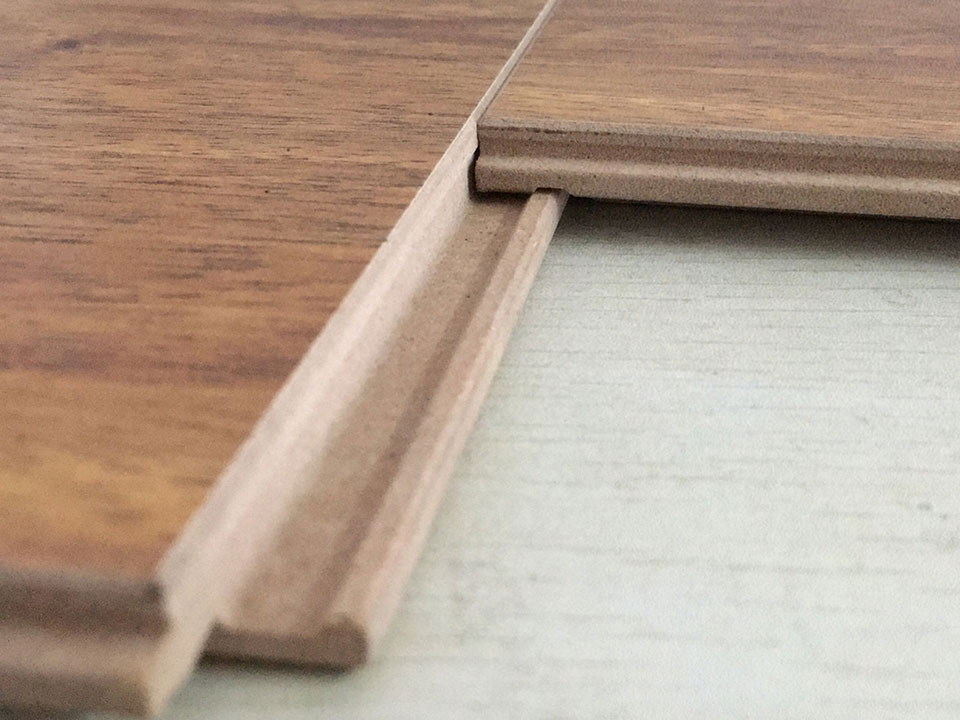

Faahfaahinta Xidhmada Dabaqa Laminateerka

| Liiska Xidhmada | ||||||||

| Cabbirka | pcs/ctn | m2/ctn | ctns/pallet | plts/20'cons | ctns/20'cont | kg/ctn | m2/20'aad | kgs/20'aad |

| 1218*198*7mm | 10 | 2.41164 | 70 | 20 | 1400 | 15 | 3376.296 | 21400 |

| 1218*198*8mm | 10 | 2.41164 | 60 | 20 | 1200 | 17.5 | 2893.97 | 21600 |

| 1218*198*8mm | 8 | 1.929312 | 70 | 20 | 1400 | 14 | 2701 | 20000 |

| 1218*198*10mm | 9 | 2.170476 | 55 | 20 | 1100 | 17.9 | 2387.5236 | 20500 |

| 1218*198*10mm | 7 | 1.688148 | 70 | 20 | 1400 | 13.93 | 2363.4072 | 20500 |

| 1218*198*12mm | 8 | 1.929312 | 50 | 20 | 1000 | 20 | 1929.312 | 20600 |

| 1218*198*12mm | 6 | 1.446984 | 65 | 20 | 1300 | 15 | 1881kii | 19900kii |

| 1215*145*8mm | 12 | 2.1141 | 60 | 20 | 1200 | 15.5 | 2536 | 19000 |

| 1215*145*10mm | 10 | 1.76175 | 65 | 20 | 1300 | 14.5 | 2290.275 | 19500kii |

| 1215*145*12mm | 10 | 1.76175 | 52 | 20 | 1040 | 17.5 | 1832kii | 18600kii |

| 810*130*8mm | 30 | 3.159 | 45 | 20 | 900 | 21 | 2843.1 | 19216kii |

| 810*130*10mm | 24 | 2.5272 | 45 | 20 | 900 | 21 | 2274.48 | 19216kii |

| 810*130*12mm | 20 | 2.106 | 45 | 20 | 900 | 21 | 1895.4 | 19216kii |

| 810*150*8mm | 30 | 3.645 | 40 | 20 | 800 | 24.5 | 2916 | 19608dii |

| 810*150*10mm | 24 | 2.916 | 40 | 20 | 800 | 24.5 | 2332.8 | 19608dii |

| 810*150*12mm | 20 | 2.43 | 40 | 20 | 800 | 24.5 | 1944kii | 19608dii |

| 810*103*8mm | 45 | 3.75435 | 32 | 24 | 768 | 27.2 | 2883 | 21289.6 |

| 810*103*12mm | 30 | 2.5029 | 32 | 24 | 768 | 26 | 1922kii | 20368 |

| 1220*200*8mm | 8 | 1.952 | 70 | 20 | 1400 | 14.5 | 2732 | 20700 |

| 1220*200*12mm | 6 | 1.464 | 65 | 20 | 1300 | 15 | 1903dii | 19900kii |

| 1220*170*12mm | 8 | 1.6592 | 60 | 20 | 1200 | 17 | 1991kii | 20800 |

Bakhaar

Kordhinta weelka sagxadda sagxadda leh -- Sagxadda

Bakhaar

Kordhinta weelka sagxadda sagxadda leh -- Kartoon

1. Ku bar sidaad keligaa u rakibi lahayd sagxadaha laamiga ah

1. Ku bar sidaad keligaa u rakibi lahayd sagxadaha laamiga ah

Tallaabada 1: Diyaarso qalabka

Qalabka loo baahan yahay:

1. Mindi utility;2. Cabbirka cajalad;3. Qalin ;4. Gacmo-gacmeed;5. Spacer;6. Dube;7. Usha ruxaysa

Shuruudaha walxaha:

1. Sagxadda sagxadda leh 2. Ciddi 3. Dusha hoose

Tallaabada 2: Diyaarinta ka hor inta aan la rakibin

1. Sagxadaha laminateerku waxay la qabsadaan deegaanka

Fadlan geli sagxadda sagxadda leh ee aad soo iibsatay qolka si loo dhigo ugu yaraan 2 maalmood ka hor, oo sii wakhti ku filan oo ay kula qabsadaan balaadhinta ama foosha heerkulka qolka iyo huurka.Tani waxay ka hortagtaa foorarsiga ama dhibaatooyinka kale ka dib rakibidda.

2. Ka saar marada

Ka saar xariiqda gooniska ee jira gidaarka adigoo isticmaalaya bir-jare.Qaybta dhinac dhig oo dib u rakib.Laminate sabeynaya (nooca loo isticmaalo mashruucan) waa in lagu rakibaa meel adag oo siman, sida vinyl.Haddii dabaqa jira uu dhaawacmo, ka saar si aad dhulka u muujiso.

Tallaabada 3: Bilow rakibidda

Qalabka saldhigga ah ee rakibidda

1. Saldhigga rakibidda

Ku rakib barkinta sagxada sagxadda sabbaynaysa.Sagxadda ka saar saxarada, cidiyaha iyo qashinka kale.Ha isku dhejin xariijimaha ku xiga, isticmaal mindida tamarta si aad u jarjartid hadba sida loogu baahdo.Xumbo suufka ayaa hoos u dhigi kara codka oo ka caawin kara sagxadda inuu dareemo dabacsanaan iyo waara.

2. Qorshaynta qaabka

Si loo go'aamiyo jihada looxa, tixgeli gidaarka ugu dheer iyo kan ugu toosan.Ka fogow xariijimaha cidhiidhiga ah ee gidaarka xudunta u ah.Looxa safka u dambeeya waa inuu ahaadaa ugu yaraan 2 inji.Ku sawir sawir farqiga 1/4 inch ee darbi kasta.

Fiiro gaar ah: Haddii ballaca safka u dambeeya uu ka yar yahay 2 inches, ballacan ku dar ballaca looxa oo dhan oo u kala qaybi 2, oo jarjar safafka hore iyo kan dambe ee looxyada ballacan.

3. Goynta shaqada

Iyadoo ku xiran qaabkaaga, waxaa laga yaabaa inaad u baahato inaad jeexdid ama jarto safka koowaad ee looxyada si dheer.Haddii aad isticmaalayso miinshaar koronto, hoos u jar dhinaca dhammaatay;haddii aad isticmaalayso miinshaar gacmeed, kor u jar dhinaca dhammaatay.Markaad goyso looxa, isticmaal xargaha si aad u hagaajisid looxa.

4. Meel kayd ah

Xirmooyinka sagxadaha sagxadda leh waxay u baahan yihiin meel bannaan oo la isku jeexo gidaarka iyo looxyada dhexdooda si looga tago 1/4 inch is-ballaarinta.Marka saxanka saldhigga la rakibo, lama arki doono.

5. Dukaan safka hore

Ku rakib dhinaca carrabka ee looxa u jeedda gidaarka (wax-soo-saareyaasha qaarkood waxay ku talinayaan in aad gooysid carrabka looxa u jeedda gidaarka).Ku xidh loox mid kale adoo isku xidhaya afafka iyo godadka.Waxa laga yaabaa in aad gacanta ugu xidhi karto looxyada si adag, ama waxa laga yaabaa inaad u baahato inaad isticmaashid ulo-xidhaha iyo dubbayaasha ku jira xirmada rakibaadda si aad isu soo jiiddo, ama aad isticmaasho baloogyada si aad isugu maroojiso kala-goysyada.Iska yaree looxa ugu dambeeya ee isku xigta ilaa dhererka (haddii ay dhererkeedu yahay ugu yaraan 12 inji, xaji qaybahan yaryar).

6. Ku rakib khadadka kale

Marka aad ku rakibayso safaf kale, ku rog tolmada safafka ku xiga ugu yaraan 12 inji, sida lagu arkay gidaarada alwaax ama leben.Caadi ahaan, waxaad bilaabi kartaa xariiq cusub oo leh qashinka la gooyey si aad u soo afjarto xariiqii hore.

7. Ku rakib xariiqda ugu dambeysa

Safka ugu dambeeya, waxaad u baahan tahay inaad ku dhejiso looxa meel xagal ah, ka dibna si tartiib ah ugu dheji meel ku dheji birta.Hubi inaad ka tagto 1/4 inch is-ballaarinta inta u dhaxaysa safka u dambeeya iyo gidaarka.

8. jar albaabka albaabka

Ha isku dayin inaad gooyso looxa si aad ugu habboonaato albaabka.Taa baddalkeeda, isticmaal miinshaar dhinac ah si aad u gooysid albaabka ilaa 1/16 inch ka sarreeya dhererka dabaqa, si qolka looxa uu u hoos simbiriirixo jirridda.Sagxadda barkinta dhig dhulka una dhow qolofka.Saar miinshaarka albaabka sare, ka dibna u goo qolofkaaga dhererka la rabo.

9. Dib u rakib walxo kale

Dib-u-soo-geli xariijinta qurxinta.Ka dib marka looxa meesha yaal, isticmaal dubbe iyo cidiyaha si aad dib ugu rakibto goonka sagxadda.Kadibna, ku dheji caaryada kabaha ee isku-dhafka ballaarinta oo isticmaal xariijimaha kala-guurka si aad ugu xirto lakabka dusha ku xiga, sida foornada ama rooga.Ha ku mudin dhulka, laakiin ku dheji qurxinta iyo darbiyada.

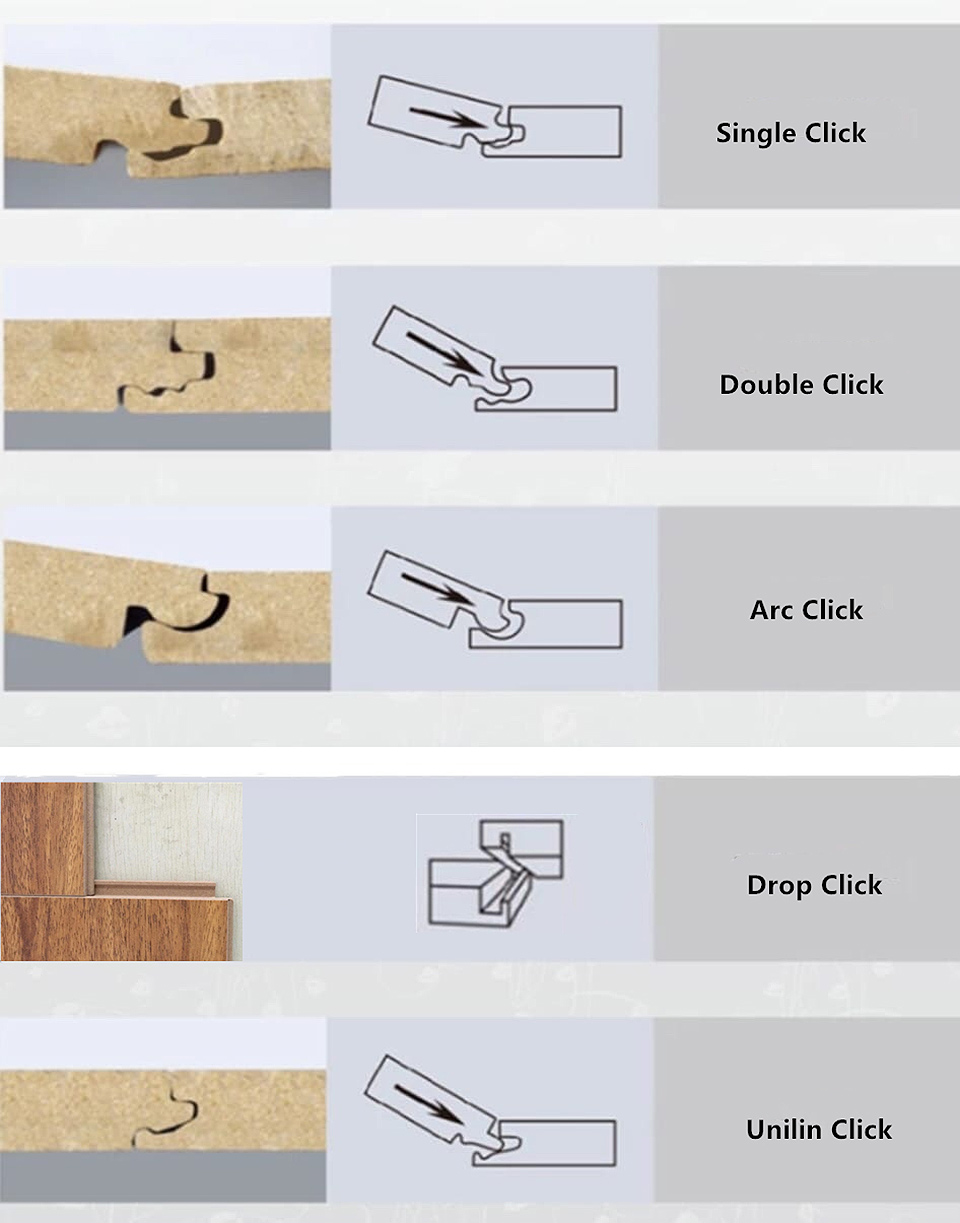

2. Nidaamka gujinta sagxadda sagxadda

2. Nidaamka gujinta sagxadda sagxadda

Waxaa ka mid ah nidaamka gujis kala duwan, kaliya guji qaabka waa ka duwan yahay , laakiin hab isku mid ah loo rakibo.

Waxaa lagu magacaabaa, hal gujis, laba jeer guji, Arc click, Drop click, Unilin guji, Valinge guji.

3. Nidaamka quful sagxadda sagxadda Laminate ee ugu cusub

3. Nidaamka quful sagxadda sagxadda Laminate ee ugu cusub

12mm Drop guji sagxadaha sagxadda dhulka hoostiisa ah faa'iidada ugu fiican waa Rakiba Degdega, Badbaadiya 50% wax ka badan oo ku dheji waqtiyada sagxadda alwaaxyada.