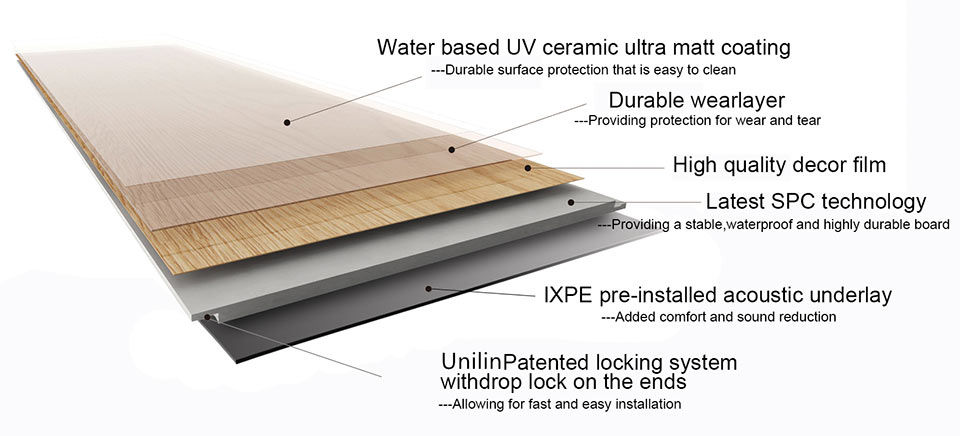

Qaab dhismeedka

Faahfaahinta Sawirada

Tilmaamid

| SPCTilmaamida Dabaqaha | |

| Koodhka Midabka | 87024 |

| Dhumucda | 3.8mm, 4mm, 4.2mm, 5mm, 5.5mm, 6mm |

| Lakabka xidho | 0.2mm, 0.3mm, 0.5mm |

| Cabbirka | 600mm*300mm |

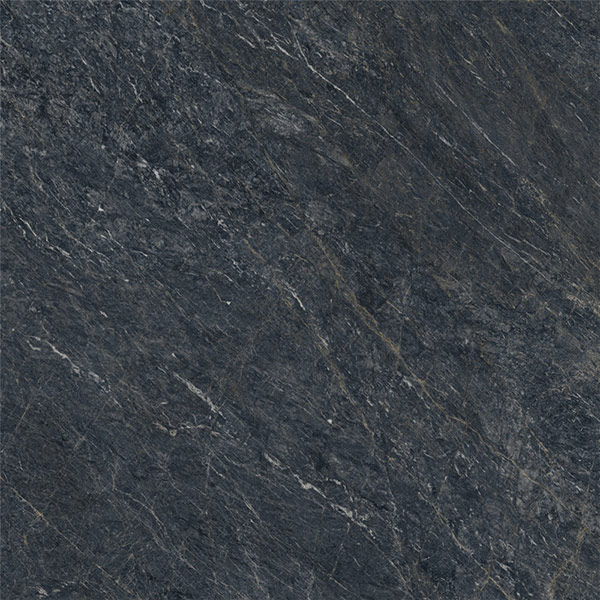

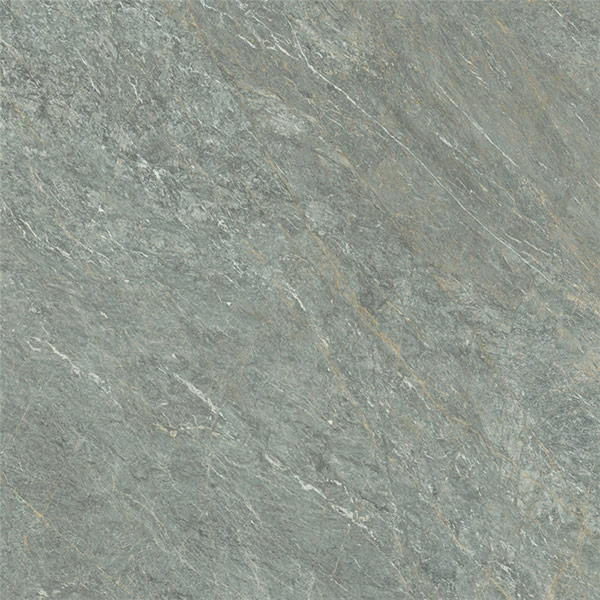

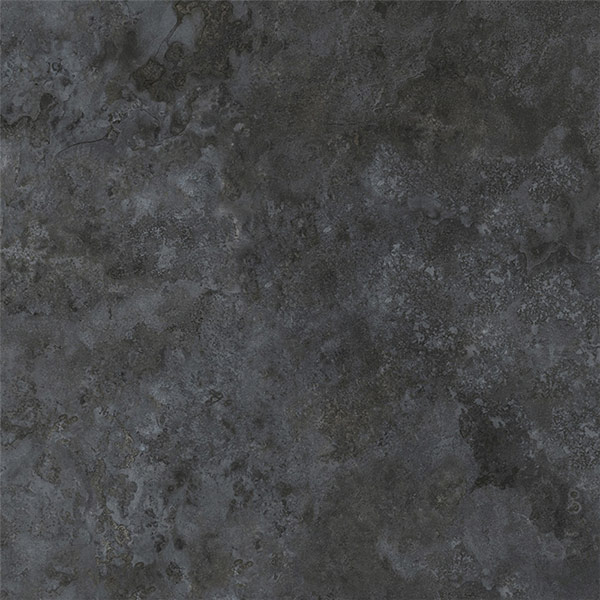

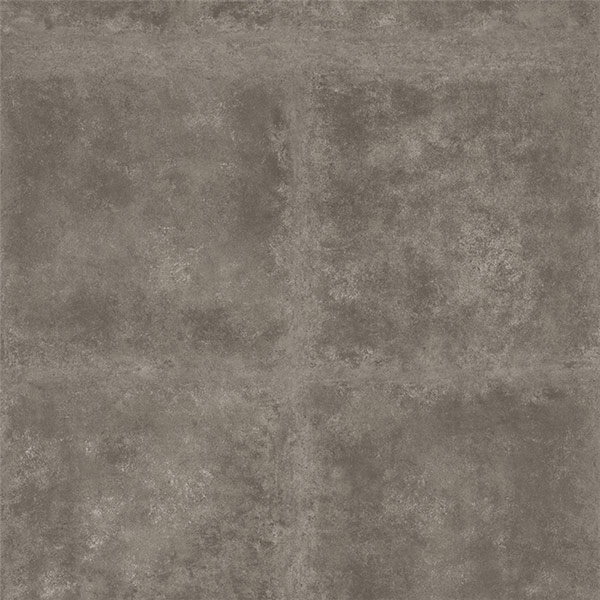

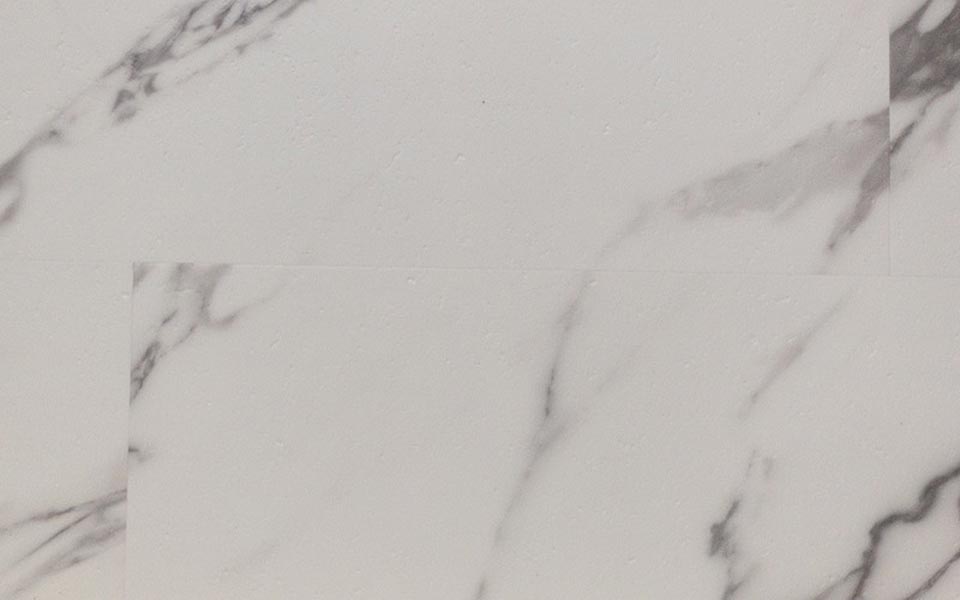

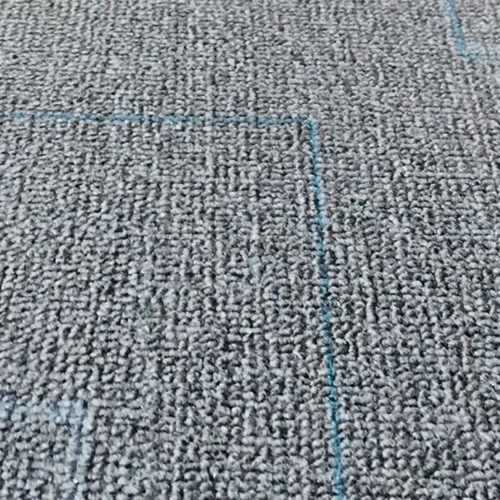

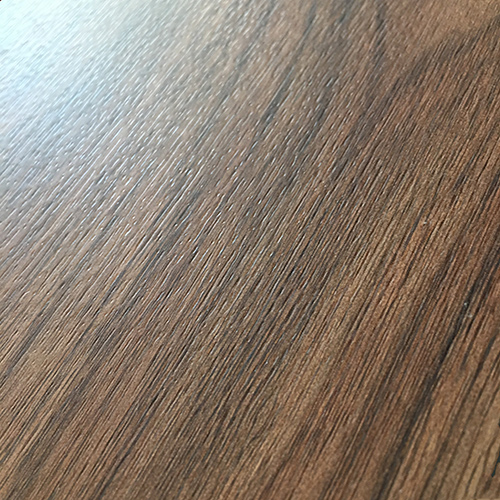

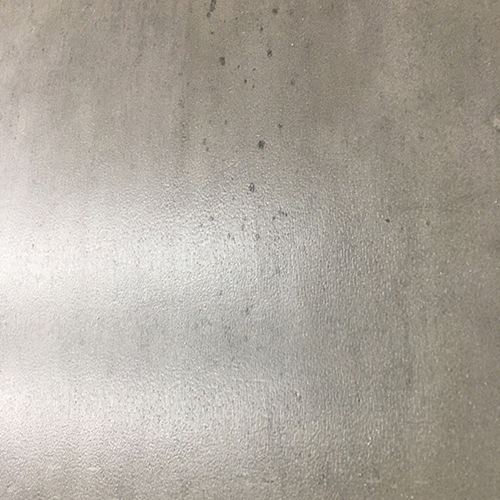

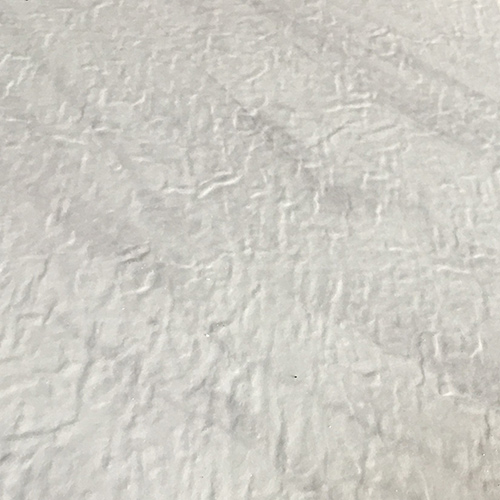

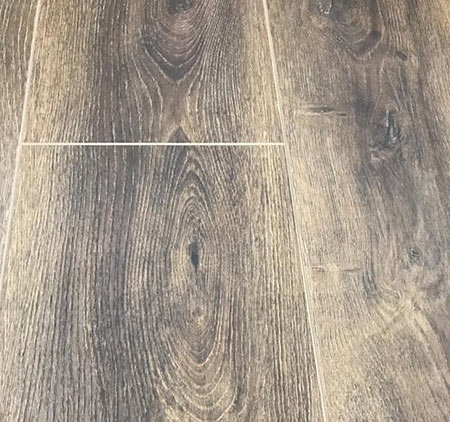

| Dusha sare | Marble, Harag, Dhagax |

| Qalabka Muhiimka ah | 100% walxo bikrad ah |

| Guji System | Unilin Guji, Quful Quful (I4F) |

| Daawaynta gaarka ah | V-Groove, Dhawaqaha EVA/IXPE |

| Habka Rakibaadda | sabayn |

Sidee loo nadiifiyaa oo loo dayactiraa Spc Vinyl?

SPC VINYL sagxadda sagxadda ayaa aad iyo aad ugu caan ah macaamiisha sababtoo ah waxqabadkeeda wanaagsan, waxaanan arki karnaa raadadka sagxadaha SPC marar badan oo kala duwan.Doorashada sagxada VINIL waxay ka tarjumaysaa dabeecadda qofka, laakiin ma taqaanaa sida loo ilaaliyo sagxadaha PVC?Maanta, waxaan kula wadaagi doonaa dayactirka iyo dayactirka sagxadaha PVC.

Mid: Ujeedada nadiifinta iyo dayactirka sagxada vinyl spc

1. Hagaajinta muuqaalka

Waqti ku habboon ka saar wasakhda ka dhalata isticmaalka maalinlaha ah, si dabaqa laastikada ah uu si buuxda u muujiyo muuqaalkiisa aan caadiga ahayn iyo dhaldhalaalka dabiiciga ah.

2. Ilaali sagxada

Dhulka laastikada ah waxaa laga ilaaliyaa kiimikooyinka shilalka ah, dabada sigaarka, calaamadaha kabaha, saliidda iyo biyaha, iwm. dabaqa vinyl.

3. Daryeelka ku habboon

Sababtoo ah qaabka dusha sare ee cidhiidhiga ah iyo daaweynta gaarka ah ee sagxadda laastikada, fiiro gaar ah u leh nadiifinta iyo dayactirka maalinlaha ah waxay ka dhigi kartaa sagxadda mid sahlan in la daryeelo oo uu sii dheereeyo noloshiisa adeegga.

Labo: Hababka maaraynta wasakhda gaarka ah ee sagxada pc

Sida aynu wada ognahay, sagxadda SPC PVC waxay leedahay faa'iidooyinka bakteeriyada bakteeriyada, barti sare, xidhashada u adkaysta iyo kuwa aan silbasho lahayn, biyuhu iyo qoyaan-cadayn, iyo dhismo habboon.Nadiifinta sayniska iyo macquulka ah iyo dayactirka kaliya ma ilaalin karto dabaqa dhalaalaya oo nadiif ah, laakiin sidoo kale waxay kordhisaa nolosha adeegga dabaqa.

1. Haddii ay jiraan boodh, walxo ama walxaha uurjiifka ah oo ku yaal dusha sare ee sagxada, fadlan nadiifi sagxada wakhtiga si aad uga ilaaliso qashinkaas inay waxyeelo u geystaan dusha sare ee sagxada oo ay keenaan dhibaato aan loo baahnayn.

2. Haddii qayb ka mid ah sagxadda dhulka ay si xun u wasakhayso, waxaad isticmaali kartaa reagent dhexdhexaad ah si aad u nadiifisid, ka dibna ku xoq dusha sagxada maro qoyan.Ha isticmaalin buraash siligga ah ama burush kale oo fiiqan si aad dhulka u xoqdo si aad uga fogaato waxyeelo soo gaadho dusha sare.

3. Marka aad si lama filaan ah dhulka ugu daadiso rinjiga, dareeraha ama daawooyinka, waa inaad si degdeg ah uga saartaa aalkolo.Haddii aad isticmaasho aashito ama dareerayaal xoog leh, waxa laga yaabaa inay balaadhiso aagga midabaysan ama waxay keeni kartaa midab.

4. Markaad isticmaasho calal qoyaan badan si aad u nadiifiso, fiiro gaar ah u yeelo dhibcaha biyaha ee ka soo galaya hadhuudhka jiifka ah ama qaybta isku xidhka, taasoo keenaysa in qaybta isku xidha ay furto.

5. Ha isticmaalin xaaqin qoyan marka aad nadiifinayso sagxadda dhukayga si aad uga ilaaliso bulaacada in ay ku xidho dusha dhuka, taas oo keenaysa in lakabka dhuxuku kor u kaco.Waxaad isticmaali kartaa xaaqin yar oo qoyan si aad u nadiifiso boodhka dusha sare ee dhulka, oo aad diirada saarto nadiifinta meelaha aadka u wasakhaysan.

6. Haddii wasakhowga saliidu dhacdo, waxaad ku nadiifin kartaa wakiil dhexdhexaad ah si aad u ilaaliso nadiifinta dusha sare ee sagxadda.

Inkasta oo dabaqa SPC VINIL uu leeyahay heer go'an oo iska caabbinta dabka ah, waxa kale oo laga yaabaa in la gubo.Sidaa darteed, markaad isticmaalayso sagxada PVC ee SPC, fadlan iska ilaali inaad si toos ah u dhigto qaar ka mid ah alaabta kulaylka ku shaqaynaysa oogada sagxada PVC si aad isaga ilaaliso waxyeelo soo gaadho sagxada.

Saddex: Goobaha daryeelka dabaqa ee pvc

1. Ka fogow waxyaalaha wasakhaysan: Inkasta oo sagxada SPC VINYL ay fududahay in la nadiifiyo, waa in laga fogaado in wasakhda la soo geliyo qolka si looga fogaado xaalad aan la nadiifin karin oo wasakhaysan oo waxyeello u geysanaysa dhulka.

2. Ka fogow xagashada walxaha fiiqan iyo waxyaalaha adag: Iska ilaali inaad qolka soo geliso walxaha fiiqan, gaar ahaan marka ay jiraan waxyaabo fiiqan oo bir ah xagga hoose, ha u jiidin dhulka si aad uga ilaaliso in sagxaddu dhaawacdo;

3. Iska ilaali in biyaha la geliyo: ka fogow xaddi badan oo biyo ah oo ku sii jira dusha sare ee sagxada muddo dheer.Haddii sagxaddu muddo dheer qoyso, waxa laga yaabaa inay soo gasho dhulka hoostiisa oo ay keento in sagxaddu dhalaasho oo ay lumiso ku dheggan.Waxa kale oo laga yaabaa inay keento wasakhowga sagxadda lakabka qoyaanka dhuka ee ka ilaaliya dusha sare Wasakhowga waxaa laga yaabaa inay gudaha u gasho dhulka oo ay keento midabka sagxadda;

4. Iska ilaali gubasho iyo gubasho: Inkasta oo Dabaqa u adkaysiga ee Maroodiga Dahabka ah uu yahay dabaq dab-demiska ah (Class B1), macnaheedu maaha in sagxaddu aanay gubi doonin rashka.Sidaa darteed, marka ay dadku isticmaalaan SPC PVC dabaqa, ha isticmaalin gubanaya dabada sigaarka, gariiradaha kaneecada, Biraha nool iyo walxaha heerkulka sare leh ayaa si toos ah loogu dhejiyaa dhulka si looga hortago waxyeellada dhulka;

5. Ka fogow iftiinka xooggan: Iska ilaali iftiin toos ah, iska ilaali shucaaca ultraviolet, kana ilaali midabka midabka iyo qallafsanaanta sagxadda.

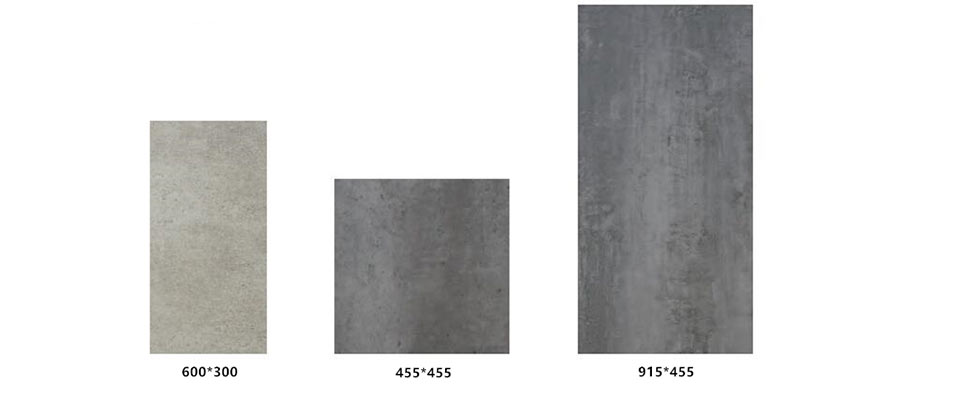

Cabbirka

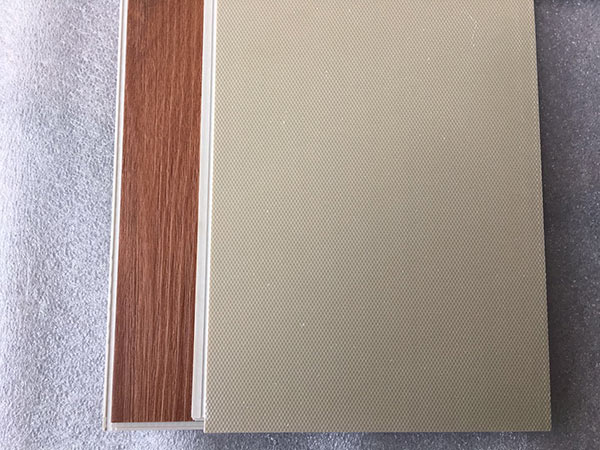

A. Spc loox

B. Spc Dusha sare

Kaalmada Dabaqa ee SPC

Taageerada IXPE

Taageerada cad ee Eva

Dhamaystir Noocyada

Dusha rooga

Dusha Crystal

Dusha Qoto dheer

Dabaqa Spc Gacma-quruxsan

Dusha maqaarka

Iftiin Leh

Dusha marmar

Qoryaha dhabta ah

Noocyada Beveled Edge

Micro V-Groove Beveled

V Groove rinji

Waa maxay Farqiga udhaxeeya 100% Dabaqa Virgin Spc iyo Sagxada Spc dib loo warshadeeyay?

Tijaabada Tayada Biyaha Aan Lahayn ee Spc

Unilin Riix

Unilin Guji 1

Unilin Guji 2

Liiska Xidhmada Dabaqa ee SPC

| Liiska Xidhmada Dabaqa ee SPC | |||||||||

| Cabbirka | sqm/pc | kgs/sqm | pcs/ctn | sqm/ctn | ctn/pallet | palette/20ft | sqm/20ft | ctns/20ft | Miisaanka Xamuulka/20ft |

| 910×148*3.8mm | 0.13468 | 7.8 | 16 | 2.15488 | 63ctn/12pallet, 70ctn/12pallet | 24 | 3439.190 | 1596 | 27300 |

| 910×148*4mm | 0.13468 | 8.2 | 15 | 2.02020 | 63ctn/6pallet, 70ctn/18pallet | 24 | 3309.088 | 1638 | 27600 |

| 910*148*5mm | 0.13468 | 10.2 | 12 | 1.61616 | 70 | 24 | 2715.149 | 1680kii | 28000 |

| 910*148*6mm | 0.13468 | 12.2 | 10 | 1.34680 | 70 | 24 | 2262.624 | 1680kii | 28000 |

| 1220*148*4mm | 0.18056 | 8.2 | 12 | 2.16672 | 72ctn/10pallet, 78ctn/10pallet | 20 | 3250.080 | 1500 | 27100 |

| 1220*148*5mm | 0.18056 | 10.2 | 10 | 1.80560 | 72 | 20 | 2600.064 | 1440kii | 27000 |

| 1220*148*6mm | 0.18056 | 12.2 | 8 | 1.44448 | 78 | 20 | 2253.390 | 1560 | 27900 |

| 1220*178*4mm | 0.21716 | 8.2 | 10 | 2.17160 | 75 | 20 | 3257.400 | 1500 | 27200 |

| 1220*178*5mm | 0.21716 | 10.2 | 8 | 1.73728 | 75 | 20 | 2605.920 | 1500 | 27000 |

| 1220*178*6mm | 0.21716 | 12.2 | 7 | 1.52012 | 70ctn/10pallet, 75ctn/10pallet | 20 | 2204.174 | 1450 | 27300 |

| 600*135*4mm | 0.0810 | 8.2 | 26 | 2.10600 | 72ctn/10pallet, 84ctn/10pallet | 20 | 3285.36 | 1560 | 27400 |

| 600*300*4mm | 0.1800 | 8.2 | 12 | 2.16000 | 72ctn/6pallet, 78ctn/14pallet | 20 | 3291.84 | 1524 | 27400 |

| 1500 * 225 * 5mm + 2mm IXPE | 0.3375 | 10.6 | 5 | 1.68750 | 64 | 21 | 2268 | 1344 | 24500 |

| 1800 * 225 * 5mm + 1.5mm IXPE | 0.4050 | 10.5 | 5 | 2.025 | 64 | 18 | 2332.8 | 1152 | 24900 |

| Fikrado: Tirada weelkiiba waxaa lagu hagaajin karaa iyadoo loo eegayo miisaanka xaddidan ee weelka ee dekeda kala duwan. | |||||||||

Faa'iidada

Tijaabada ka hortagga xoqitaanka sagxada SPC

Baaritaanka Dabaqa Dabka ee SPC

Imtixaanka Dabaqa ee SPC ee biyuhu

Codsiyada

Mashruuca Dabaqa Blackbutt Spc ee Australia - 1

Mashruuci Sagxada Xajka Spc ee Australia - 2

Habka Ilaalinta Dabaqa ee SPC

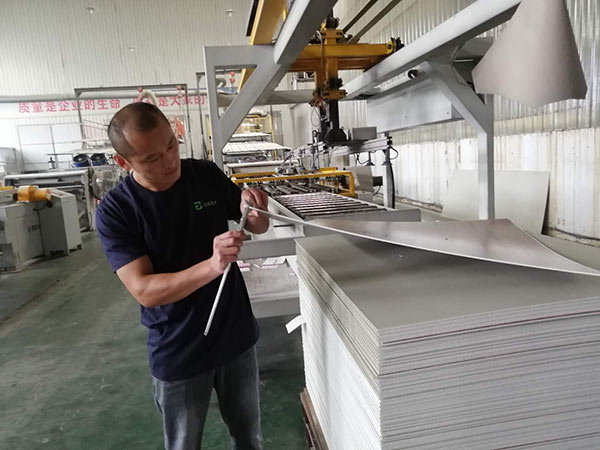

1 Workshop

4 Guddiga Caafimaadka ee SPC

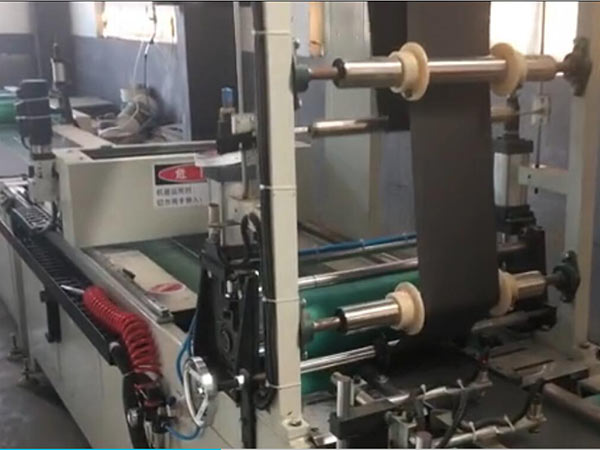

7 SPC Riix Macking Machine

10 Bakhaar

2 SPC Coextrusion Machine

5 Imtixaanka Tayada SPC

8 Mashiinka Xumbo Ku Darida

11 Soodejinaya

3 Mashiinka UV

6 Mashiinka Goynta SPC/strong>

9 Shaybaadhka

A. Riix Rakibaadda Dabaqadda Spc

A. Riix Rakibaadda Dabaqadda Spc

B. Unilin Guji Rakibaadda Dabaqa Spc

B. Unilin Guji Rakibaadda Dabaqa Spc

Habka rakibida sagxada SPC

Habka rakibida sagxada SPC

1. Marka hore, go'aami sida aad rabto in sagxaddu u socoto.Caadi ahaan alaabta looxa, sagxaddu waxay socotaa dhererka qolka.Waxaa laga yaabaa inay jiraan waxyaabo ka reeban maadaama ay dhammaan tahay arrin la doorbidayo.

2. Si aad uga fogaato ballaadhka looxa dhuuban ama dhererka looxyada gaagaaban ee darbiyada/albaabada agtooda, waxaa muhiim ah in la sameeyo qorshe hore.Adiga oo isticmaalaya ballaca qolka, xisaabi inta loox oo buuxa oo ku habboon aagga iyo inta boos ee ka hadhay ee u baahan doona in lagu daboolo looxyo qayb ah.Meesha soo hartay laba u kala qaybi si aad u xisaabiso ballaca looxyada qayb ahaan.Isla sidaas oo kale u samee dhererka.

3. Ogsoonow in safka hore ee looxa uusan u baahnayn in la gooyo ballac ahaan, waxay noqon doontaa lagama maarmaan in la gooyo carrabka aan la daboolin si ay nadiif ah oo adag u noqoto derbiga.

4. 8mm farqiga ballaarinta waa in laga ilaaliyaa derbiga inta lagu jiro rakibidda.Tani waxay u ogolaan doontaa meel bannaan oo bannaan balaadhinta dabiiciga ah iyo foosha ee looxyada.

5. Looxyada waa in lagu rakibaa midig ilaa bidix.Laga soo bilaabo cidhifka midig ee sare ee qolka, dhig looxa ugu horreeya ee meesha si ay labada madaxa iyo tolmada dhinacyadu u muuqdaan.

6. Ku rakib looxa labaad ee safka kowaad adigoo xagal u siinaya carrabka dhinaca gaaban ee jeexdin dhinaca dheer ee looxa kowaad.

7. Si aad u bilawdo safka labaad, gooy loox ka gaaban looxa ugu yaraan 152.4mm ka yar adiga oo afka dhinaca dheer gelinaya godka safka hore ee looxa.

8. Ku rakib looxa labaad ee safka labaad adigoo gelinaya carrabka dhinaca gaaban ee hore loo rakibay looxa dhinaca dheer ee hore.

9. Isku toosi looxa si cidhifka carrabka dhinaca gaaban uu u dul istaago bishinta jeexdin ee looxa safka kowaad.

10. Adigoo isticmaalaya xoog dabacsan oo xagal 20-30 darajo ah, ku riix carrabka dhinaca gaaban ee godadka looxa ku dheggan adiga oo ku sixiya dhinaca tolka dheer.Waxa laga yaabaa in aad u baahato in aad u yar kor u qaaddo looxa dhinaca midigta si aad u oggolaato ficilka "simbiriirixidda".

11. Looxyada soo haray waxaa lagu dhejin karaa qolka iyadoo la adeegsanayo farsamo isku mid ah.Hubi in meelaha banaan ee balaadhinta loo baahan yahay lagu ilaaliyo dhammaan qaybaha toosan (sida gidaarada, albaabada, armaajooyinka iwm).

12. Looxa waxaa si fudud loogu goyn karaa mindi adeeg, kaliya dhali dusha sare ee looxa oo labo u kala qaad.

Naqshadaynta sagxadaha sagxada Spc

Naqshadaynta sagxadaha sagxada Spc

| Sifada | Tilmaamaha Imtixaanka iyo Natiijada |

| Cabbirrada (ininch) | 6×36;6×48;7×48;8×48;9×48;12×24;12×48;12×36;18×36 |

| Dhumucda | 3.8mm, 4.0mm, 4.5mm, 5.0mm, 5.5mm, 6.0mm |

| Lifaaqa / Taageerada | 1.5mm ama 2.0mm IXPE iyo EVA |

| Squareness | ASTM F2055 - Gudub - 0.010 in. ugu badnaan |

| Baaxadda iyo Dulqaadka | ASTM F2055 - Gudub - +0.016 cag toosan |

| Dhumucda | ASTM F386 - Gudub - Magac ahaan +0.005 in. |

| Dabacsanaan | ASTM F137 - Gudub - ≤1.0 in., ma dillaaco ama dillaac |

| Deganaanshaha cabbirka | ASTM F2199 - Gudub - ≤ 0.024 in. cag toosan |

| Joogitaanka Birta Culus / Maqnaanshaha | TS EN 71-3 C - Waxay buuxisay shuruudaha(Lead, Antimony, Arsenic, Barium, Cadmium, Chromium, Mercury iyo Selenium). |

| Iska caabinta Jiilka qiiqa | TS EN ISO 9239-1 (Flux Halis ah) Natiijooyinka 9.1 |

| Iska caabinta Jiilka qiiqa, Qaabka aan ololayn | EN ISO |

| Daboolida | ASTM E648- Heerka 1 Qiimaynta |

| Gelitaan Hadhaaga ah | ASTM F1914 - Gudub - Celcelis ahaan in ka yar 8% |

| Xadka Load Joogta ah | ASTM-F-970 wuxuu dhaafaa 1000psi |

| Shuruudaha Wear Group pr | EN 660-1 Dhumucda dhumucda 0.30 |

| Iska caabin simbiriirixan | ASTM D2047 - Gudub -> 0.6 qoyan, 0.6 qallalan |

| Iska caabinta Iftiinka | ASTM F1515 - Gudub - ∧E ≤ 8 |

| Iska caabinta kulaylka | ASTM F1514 - Gudub - ∧E ≤ 8 |

| Dhaqanka Korontada (ESD) | TS EN 1815: 1997 2,0 kV markii lagu tijaabiyay 23 C+1 C |

| Kuleylinta Dabaqa hoose | Ku habboon rakibida kuleyliyaha sagxadda hoostiisa |

| Ku-laabashada Ka dib Kulaylka Soo-gaadhista | EN 434 <2mm kaarka |

| Waxyaabaha Vinyl-ka dib loo warshadeeyay | Ku dhawaad 40% |

| Dib u warshadaynta | dib ayaa loo warshadayn karaa |

| Damaanadda Alaabta | 10-Sano Ganacsi & Deganaanshaha 15-Sano |

| Floorscore shahaado | Shahaadada la bixiyo Marka la codsado |