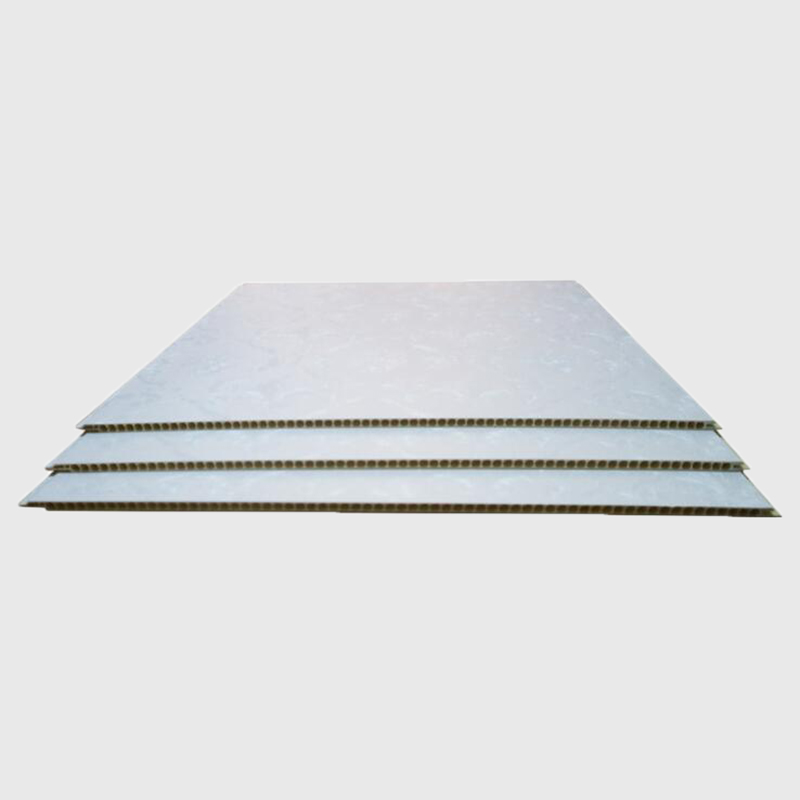

Interior Wpc Wall Panel and SPC Wall Panel Effect picture for Background Wall

What is Bathroom Panels advantage?

1. The production process of Bathroom Panels has the same machinability as logs. It can be nailed, sawed, cut, and can be drilled.

Only need to use nails or bolts to fix the Panels, the surface texture is very smooth, no need to spray paint. In addition, compared to logs, wall panels have more physical advantages and good stability. In daily use in China, there will be no cracks, warped edges, and diagonal lines. According to the needs of consumers, colorants can be put into PANEL products with different colors after processing, but they need regular maintenance.

2. Due to its own characteristics, PVC WALL PANEL is particularly water-resistant and good in fire resistance. At the same time, PVC WALL is environmentally friendly and corrosion-resistant and does not require excessive maintenance.

3. The appearance and texture of Pvc Bathroom panels are very similar to solid wood, but compared to WPC wallboard materials, they have higher hardness and can last longer. In addition, the wall panel is light in weight, convenient for construction personnel to transport and install, and has a certain degree of wear resistance, making WALL PANEL suitable for walls in many spaces.

4. Pvc Panel has many patterns and rich colors, giving consumers more choices. The wall panel installation is very convenient. After the overall wall decoration, the decoration taste can be improved instantly. It is widely used in indoor walls, such as entertainment venues, hotels, conference centers, offices, etc.

5. In the production process of Bathroom PVC panel, flame-retardant materials are added to make the product excellent in fire resistance. It will be extinguished in case of fire and improve safety. At the same time, it is very convenient to take care of and clean. Just use a rag to wipe off the stains, making consumers more worry-free.

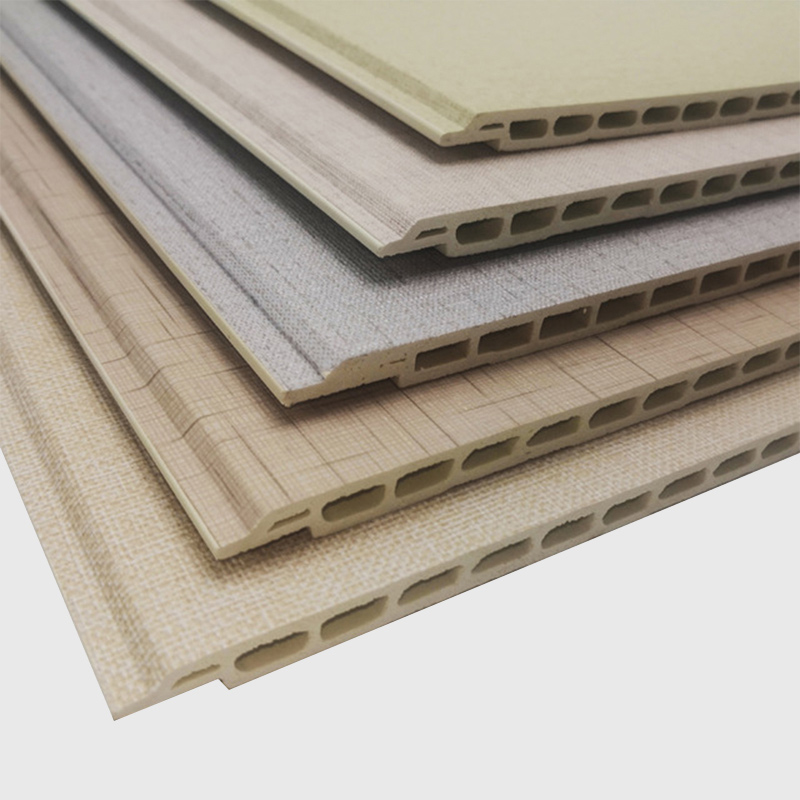

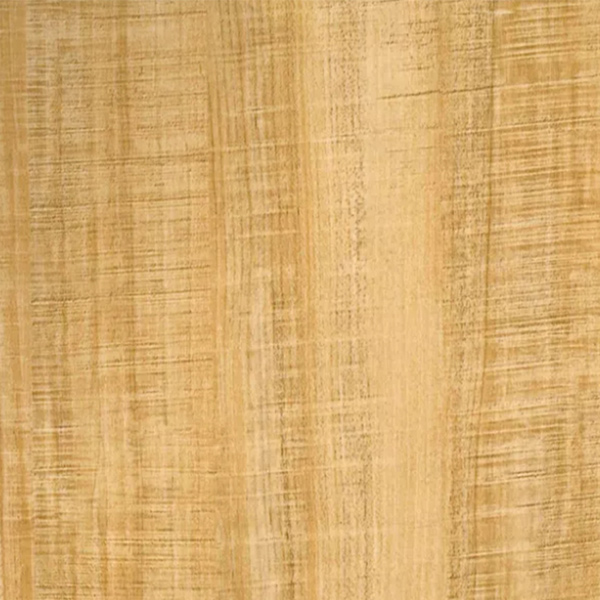

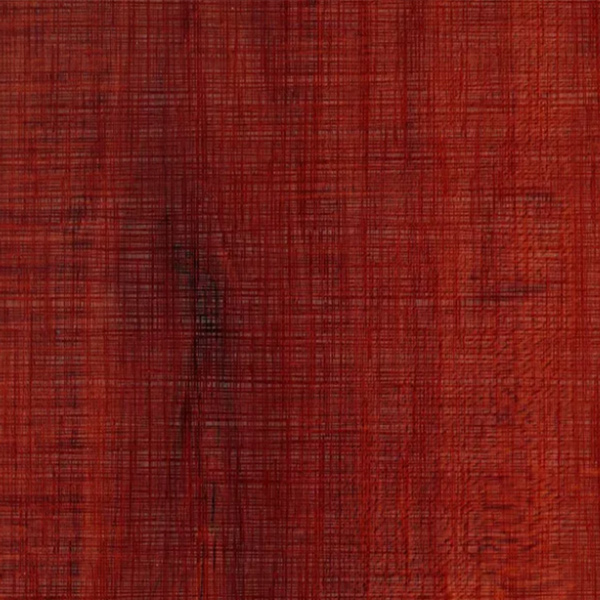

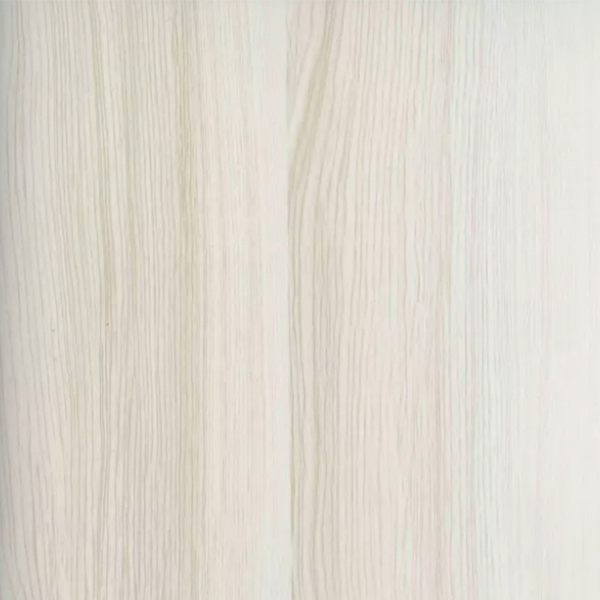

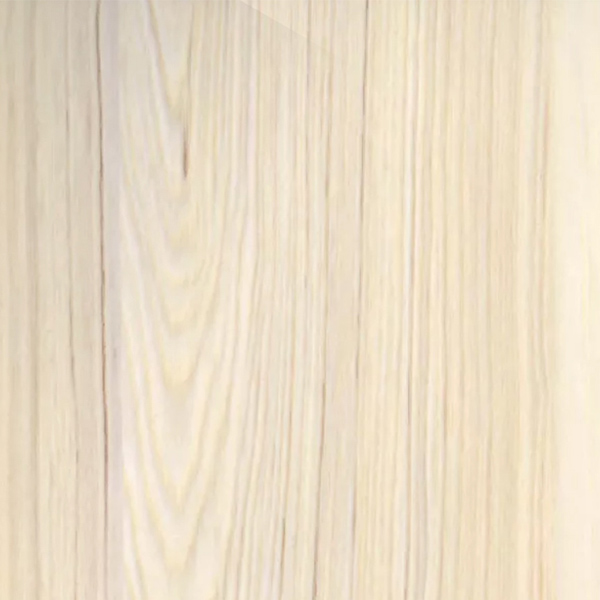

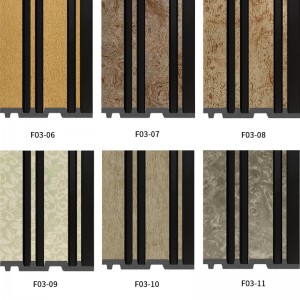

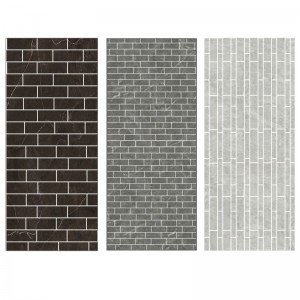

Multiple Colors

Size

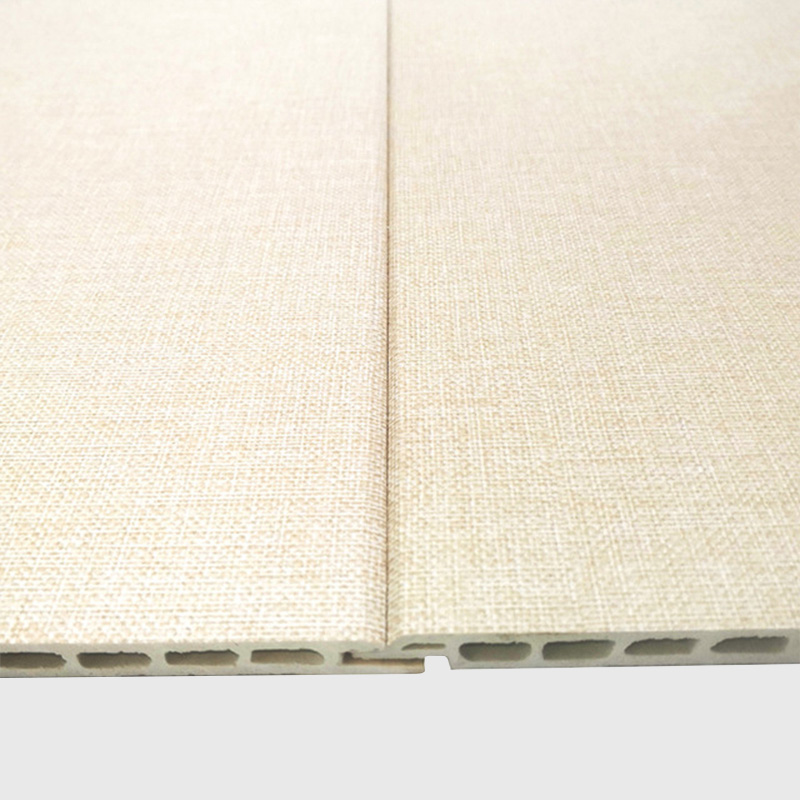

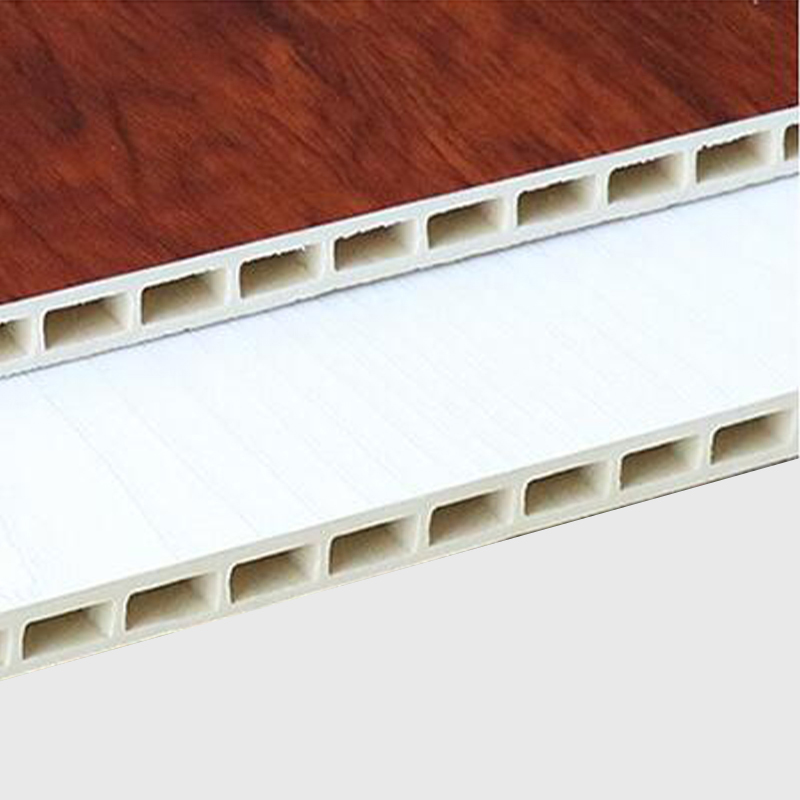

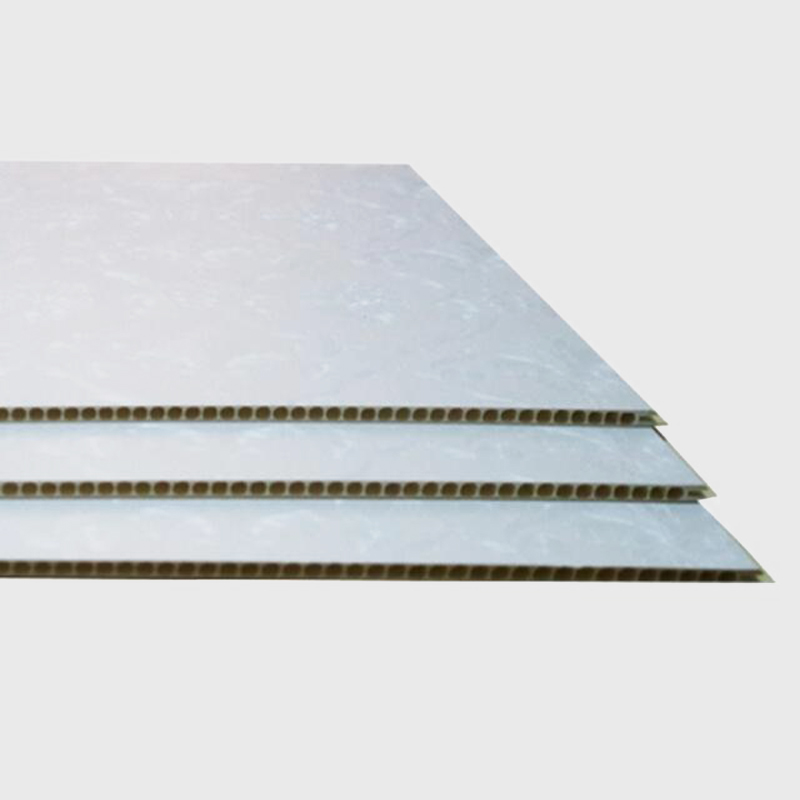

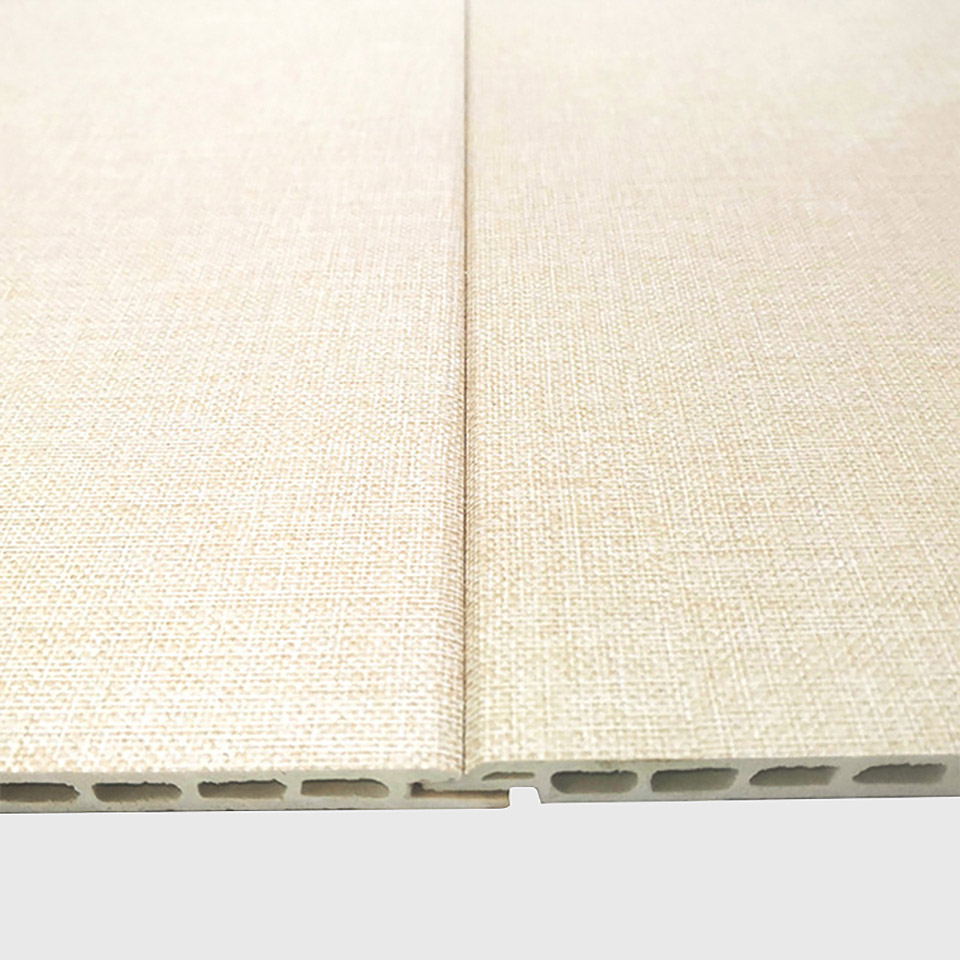

Detail Image

Joint Tyle

Specification

| Product name | Indoor wpc spc wall panel for home |

| Brand | DEGE |

| Hs code | 3925900000 |

| Model | Wall Paper color design |

| Size | 600*9mm |

| Lenghth | 2.8 Meter or or Customized |

| Surface | Pvc Film Laminated |

| Material | SPC: Stone Pvc Composite.PVC resin powder, light calcium powder and other auxiliary materials |

| Color | Oak,Gold, Mahogany, Teak, Cedar, Red , Classic grey, Black walnut |

| Minimum order | Full 20ft Container , 500 meters per Color |

| Package | Standard canton |

| Water absorption | Less than 1% |

| Flame- retardant level | Level B |

| Payment term | 30%T/T in advance,remainder 70% paid before shipment |

| Delivery period | Within 30 days |

| Remark | The color and the size can be changed according to customer request |

| Application

Advantage

|

Hotels, commercial buildings, hospital, schools, home kitchen, bathroom, interior decoration and so on |

| 1) Dimensional stability, longevity, natural feel | |

| 2) Resistance to rot and crack | |

| 3) Stable over a wide temperature range, weather-resistant | |

| 4) Moisture resistant, low flame spread | |

| 5) High impact resistant | |

| 6) Outstanding screw and nail retention | |

| 7) Environmentally friendly, recyclable | |

| 8) Broad range of finished and appearance | |

| 9) Easily produced and easily fabricated | |

| 10) Contains no toxic chemicals or preservatives |

Advantage

Finished Goods Image

Applications

Project

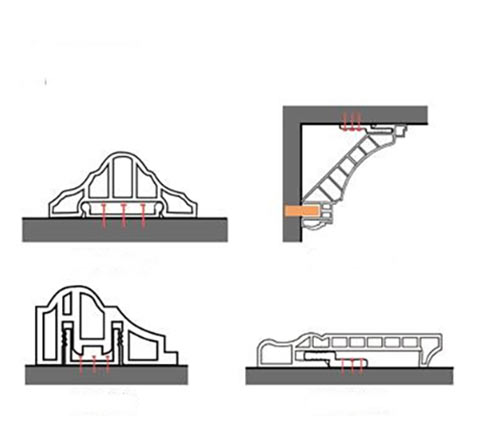

Wall Panel Installation

Wall Panel Installation

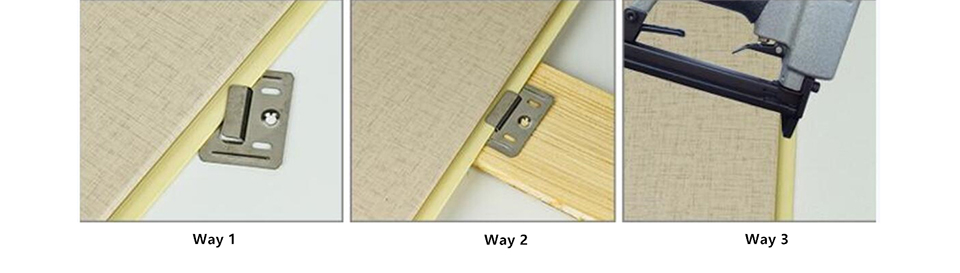

Way 1: Nail the wall panel directly to the wall through the metal cllip

Way 2: Install the keel on the wall first, and directly nail the wall panel to the keel through the metal clip

Way 3: Nail the wall panel to the wall directly with an air nail gun

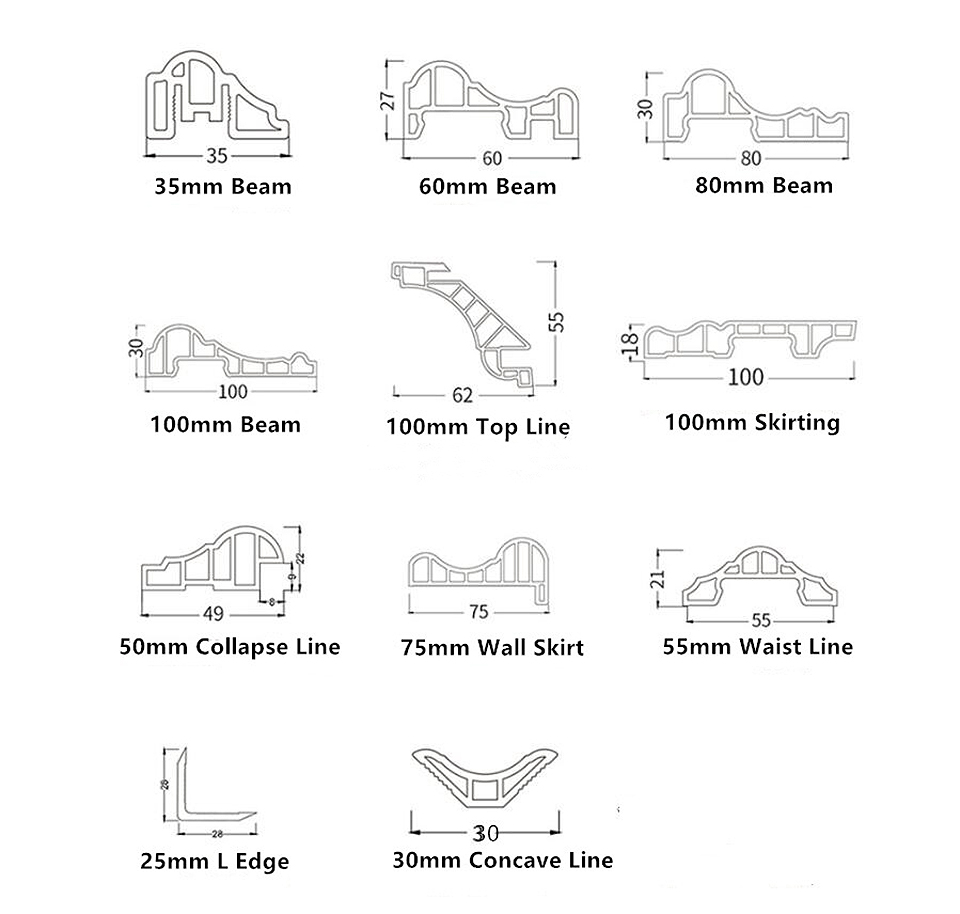

Wall Panel Accessories Design and Installation

Wall Panel Accessories Design and Installation

Installation tips:

Fix the Pvc Buckle on the wall first, then snap the accessories into the pvc Buckle

| Characteristic | Test Specification and Result |

| Squareness | ASTM F2055 – Passes – 0.020 in. max |

| Size and Tolerance | ASTM F2055 – Passes – +0.015 in per linear foot |

| Thickness | ASTM F386 – Passes – Nominal +0.006 in. |

| Flexibility | ASTM F137 – Passes – ≤1.1 in., no cracks or breaks |

| Dimensional Stability | ASTM F2199 – Passes – ≤ 0.025 in. per linear foot |

| Heavy Metal Presence / Absence | EN 71-3 C — Meets Spec. (Lead, Antimony, Arsenic, Barium, Cadmium, Chromium, Mercury and Selenium). |

| Smoke Generation Resistance | EN ISO 9239-1 (Critical Flux) Results 9.2 |

| Smoke Generation Resistance, Non-Flaming Mode | EN ISO |

| Flammability | ASTM E648- Class 1 Rating |

| Residual Indentation | ASTM F1914 – Passes – Average less than 8% |

| Static Load Limit | ASTM-F-970 Passes 1000psi |

| Requirements for Wear Group pr | EN 660-1 Thickness Loss 0.30<I<0.60 prEN 660-2 Volume Los 7.6<F <15.0 |

| Slip Resistance | ASTM D2047 – Passes – > 0.6 Wet, 0.6 Dry |

| Resistance to Light | ASTM F1515 – Passes – ∧E ≤ 9 |

| Resistance to Heat | ASTM F1514 – Passes – ∧E ≤ 9 |

| Electrical Behavior (ESD) | EN 1815: 1997 2,0 kV when tested at 23 C+1 C |

| Underfloor Heating | Suitable for installing over under floor heating. |

| Curling After Exposure to Heat | EN 434 < 1.8mm pass |

| Recycled Vinyl Content | Approximately 40% |

| Recyclability | Can be recycled |

| Product Warranty | 10-Year Commercial & 15-Year Residential |

| Floorscore Certified | Certificate Provided Upon Request |