Wooden terraces are the dream of many homeowners, but they have their pitfalls: wood turns grey, cracks, splinteres and weathers. None of this applies to “WPC terraces” made of a wood-plastic mixture. Laying is easy, but the preparatory work should not be underestimated.

They are often called barefoot boards because they are very comfortable to walk on with bare feet and because they certainly do not splinter: The WPC terrace boards. Their secret is the material. Instead of valuable, often tropical solid wood, the finest wood chips are bound with a plastic and shaped. In modern German, the material is called “Wood-Plastic-Composite” or “WPC” for short.

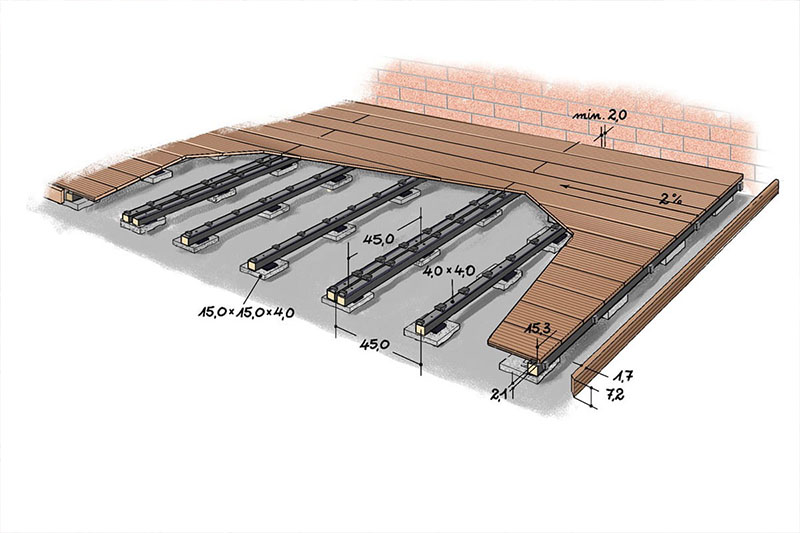

All manufacturers of these decking boards always offer a complete system of boards and substructure. This makes creating a new terrace relatively easy. You only have to pay meticulous attention to the right slope away from the house during the preparatory work.

First of all: The system is mature and works well. It works less well if you do not remove the old terrace covering for reasons of time or effort. Then you cannot create an evenly level subsurface and you have to level out every unevenness in the old covering.

On this occasion, it makes sense to adapt the terrace to the floor level of the adjoining living room. Since the WPC material is significantly more elastic than solid wood, the substructure lies on a relatively close-meshed grid of concrete slabs.

The associated concrete screws, which anchor the substructure in the panels without dowels, worked perfectly. Even if you should plan two full weekends of construction, in the end your dream of a terrace will come true.

Post time: Nov-09-2022