What is 3D Embossing Composite flooring ?

3D Embossing Composite flooring is a new type of environmentally friendly wood-plastic composite product. The wood phenol produced during the production of high-density fiberboard is added to recycled plastic and passed through pelletizing equipment to make wood-plastic composite material, and then the extrusion production group is made into wood Plastic floor.

The surface is Hot press to 3D Embossing real wooden surface , it looks more natural .

Composite Flooring Advantage:

(1) Waterproof and moisture-proof. It fundamentally solves the problem that wood products are easy to rot and swell and deform after absorbing water in humid and watery environments, and can be used in environments where traditional wood products cannot be used.

(2) Anti-insect and anti-termite, effectively prevent pest harassment and prolong service life.

(3) It is colorful, with many colors to choose from. It not only has natural wood feel and wood texture, but also can customize the color you need according to your own personality

(4) It has strong plasticity, can realize individualized modeling very simply, and fully reflects individual style.

(5) High environmental protection, no pollution, no pollution, and recyclable. The product does not contain benzene, and the formaldehyde content is 0.2, which is lower than the EO standard. It is the European environmental protection standard. It can be recycled and greatly saves the amount of wood used. It is suitable for the national policy of sustainable development and benefits the society.

(6) High fire resistance. It can be effectively flame-retardant, with a fire-proof rating of B1, self-extinguishing in case of fire and does not produce any toxic gas.

(7) Good workability, can be ordered, planed, sawed, drilled, and the surface can be painted.

(8) The installation is simple, the construction is convenient, no complicated construction technology is needed, and the installation time and cost are saved.

(9) No cracking, no swelling, no deformation, no maintenance and maintenance, easy to clean, saving later repair and maintenance costs.

(10) Good sound-absorbing effect and good energy-saving performance, making indoor energy saving up to 30% or more.

Structure

Details Images

WPC Decking Specifications

| Material | 7% SURLYN, 30% HDPE, 54% Wood Powder, 9% Chemical Additives |

| Size | 140*23mm, 140*25mm, 70*11mm |

| Length | 2200mm, 2800mm, 2900mm or Customized |

| Color | Charcoal, Rosewood, Teak, Old Wood, Light Grey, Mahogany, Maple, Pale |

| Surface Treatment | Embossed, Wire-brushed |

| Applications | Garden, Lawn, Balcony, Corridor, Garage, Pool Surrounds, Beach Road, Scenic, etc. |

| Lifespan | Domestic: 15-20 years, Commercial: 10-15 years |

| Technical Parameter |

Flexural failure load: 3876N (≥2500N) Water absorption:1.2% (≤10%) Fire-retardant: B1 Grade |

| Certificate | CE, SGS, ISO |

| Packing | About 800sqm/20ft and about 1300sqm/40HQ |

Color Available

Coextrusion WPC Decking Surfaces

Package

Product Process

Applications

Project 1

Project 2

Project 3

Wpc Decking Accessories

Wpc Decking Accessories

L Edge

L Edge  Plastic clips

Plastic clips  Stainless steel clips

Stainless steel clips  Wpc keel

Wpc keel

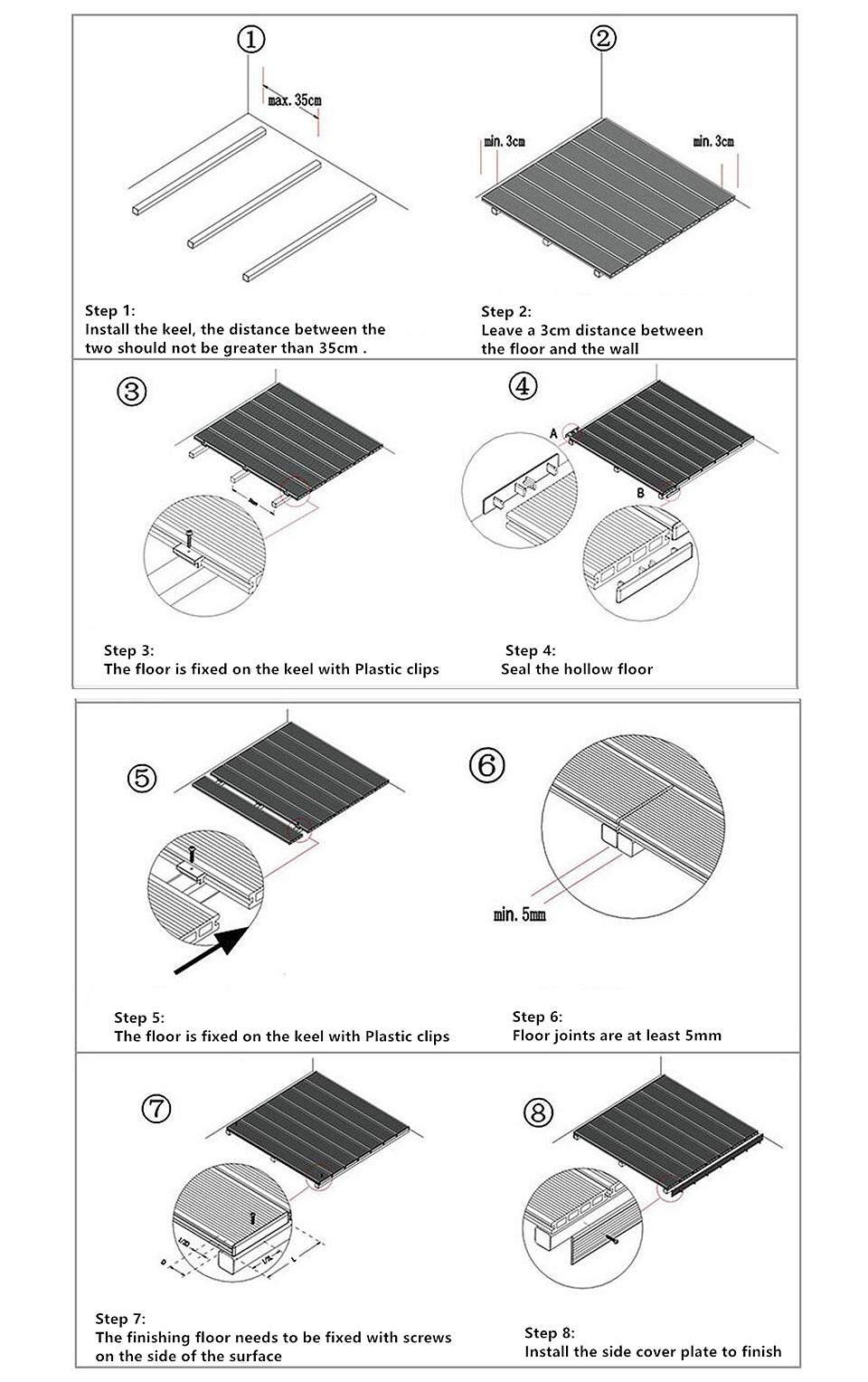

Wpc Decking Installation Steps

Wpc Decking Installation Steps

| Density | 1.35g/m3 (Standard: ASTM D792-13 Method B) |

| Tensile strength | 23.2 MPa (Standard: ASTM D638-14) |

| Flexural strength | 26.5Mp (Standard: ASTM D790-10) |

| Flexural Modulus | 32.5Mp (Standard: ASTM D790-10) |

| Impact strength | 68J/m (Standard: ASTM D4812-11) |

| Shore hardness | D68 (Standard: ASTM D2240-05) |

| Water absorption | 0.65%(Standard: ASTM D570-98) |

| Thermal expansion | 42.12 x10-6 (Standard: ASTM D696 – 08) |

| Slip resistant | R11 (Standard: DIN 51130:2014) |