Parameter

| Color | We have several hundreds of color for your choice. | ||

| Thickness | 7mm, 8mm, 10mm, 12mm are available. | ||

| Size | 1218*198,1218*168,1218*148,1218*128, 810*130,810*148,800*400,1200*400,600*100 | ||

| Surface treatment | More than 20 kinds of surface, such as Embossed, Crystal, EIR, Handscraped, Matt, Glossy, Piano etc. | ||

| Edge treatment | Square Edge ,Mold press U-groove , 3 strips U grovoe, V-Groove with painting, bevel painting, waxing, padding, press etc. are provided. | ||

| Special treatment | Press U-groove,Painted V-groove,Waxing, Logo painted on back ,Soundproof EVA/IXPE | ||

| Wear Resistance | AC1,AC2, AC3,AC4, AC5 standard EN13329 | ||

| Base materials | 770 kg /m³,800 kg /m³, 850 kg /m³ and 880 kgs /m³ | ||

| Click system | Unilin Double , Arc , Single , Drop ,Valinge | ||

| Installation Method | Floating | ||

| Formaldehyde Emission | E1<=1.5mg/L, or E0<=0.5mg/L | ||

How to Choose China wood laminate floor design for your house ?

China Wood Laminate Floor Color Types:

Choose which kind of floor looks good and resistant to dirt, and which kind of floor matches the furniture more harmoniously.It is a professional skill.

First of all, we must understand the classification of flooring colors. Generally, flooring colors are divided into three categories, light color, natural color and dark color.

1. Light-colored floor: including white Pine, light gray Oak and light yellow Ash and other visually lighter and lighter colors LAMINATE WOOD FLOORING. The light-colored floor features, the visual feature is soft, will not become a prominent place in the living room or the entire space, not eye-catching, comfortable.

2. natural wood color : refers to the intermediate color between light and dark colors, closer to the color of the wood itself. The original wood floor is visually darker than the light color, and has a relatively original ecological texture, good comfort, and a more versatile color.

3. Dark floor: brown , red,brown and black are relatively dark, such as walnut, red sandalwood and other wooden design.

The characteristics of dark floor: Relatively calm temperament, high requirements on the size of the living room space and lighting.

How to decide which China laminate floor color suitable to Home?

1. The floor color is determined by daylighting: general daylighting: try to choose light-colored or natural wood color laminate flooring.

Light-colored + high-gloss floors will brighten up the environment with poor lighting. As for why the lighting is poor, it is not recommended to use dark floors? Because the dark floor itself is darker in color, and poor lighting, it will aggravate the dark and heavy indoor feeling.

2. The floor color is determined by the area of the living room: light color or natural wood color is selected for the small area, and there is no limit to the choice of large living room, and the dark color is more atmospheric.

Note:

Why is it recommended that you choose light-colored floors for small apartments? Because the light color is close to the wall and ceiling colors, it can blur each interface and make the space more spacious.

Dark floors will compress the space, but are especially suitable for large units. In particular, dark floors with fine texture will make the overall collocation calm and atmospheric, and can suppress the aura. Many large-sized luxury homes prefer dark floors.

3. Determined by the floor height of the house: If the floor height is enough, you can boldly try the dark floor. The floor height is too low and the overall space is depressed. Choosing a light-colored floor will make the space more comfortable.

4. Determined by the decoration style: The general style will determine the choice of floor color. For example, Nordic style and Japanese style decoration can be matched with light or natural wood floors; American, modern or industrial styles can be matched with dark floors.

Which China laminate wood floor is more stain resistant

The floor color is different, the matching effect is also different, and the degree of stain resistance is also different. So if you are worried about cleaning troubles, choose the right color of the floor

1. In theory, dark floors will be more resistant to dirt. The dark floor is dark in color, so some dirt is less noticeable. However, dark floors are not resistant to dust, that is, dust and footprints are particularly obvious. If one foot is a mold, dust will be particularly obvious.

2. The light-colored floor is not resistant to dirt, and it is easy to see dirt such as hair, but it is resistant to dust. Light-colored floors make it easy to see dark trash or dirt, so they are not resistant to dirt, especially those with severe hair loss. Hair can basically be seen all over the floor. But the dust is not obvious.

Choose the appropriate China wood laminate floor colors according to the above-mentioned principles, and choose it after comprehensive consideration of lighting, area, floor height, stain resistance, style, etc.

Surface Available

Big Embossed Surface

Piano Surface

Handscraped Surface

Mirror Surface

EIR Surface

Small Embossed Surface

Real Wood Surface

Crystal Surface

Middle Embossed Surface

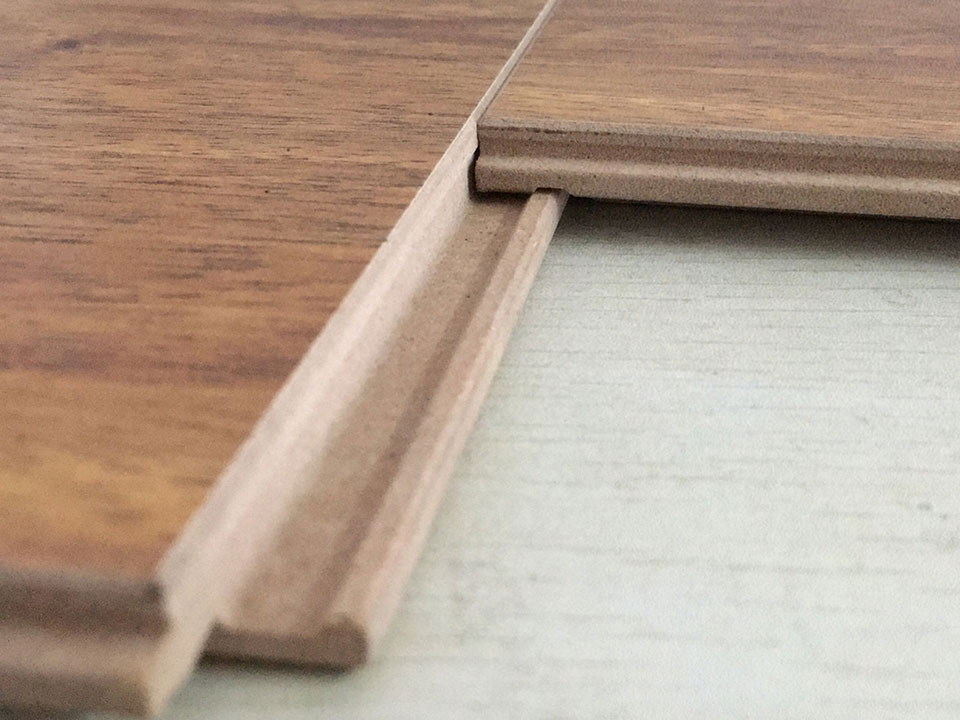

Click Systems Available

Joint Available

Back Colors Available

Special Treatments Available

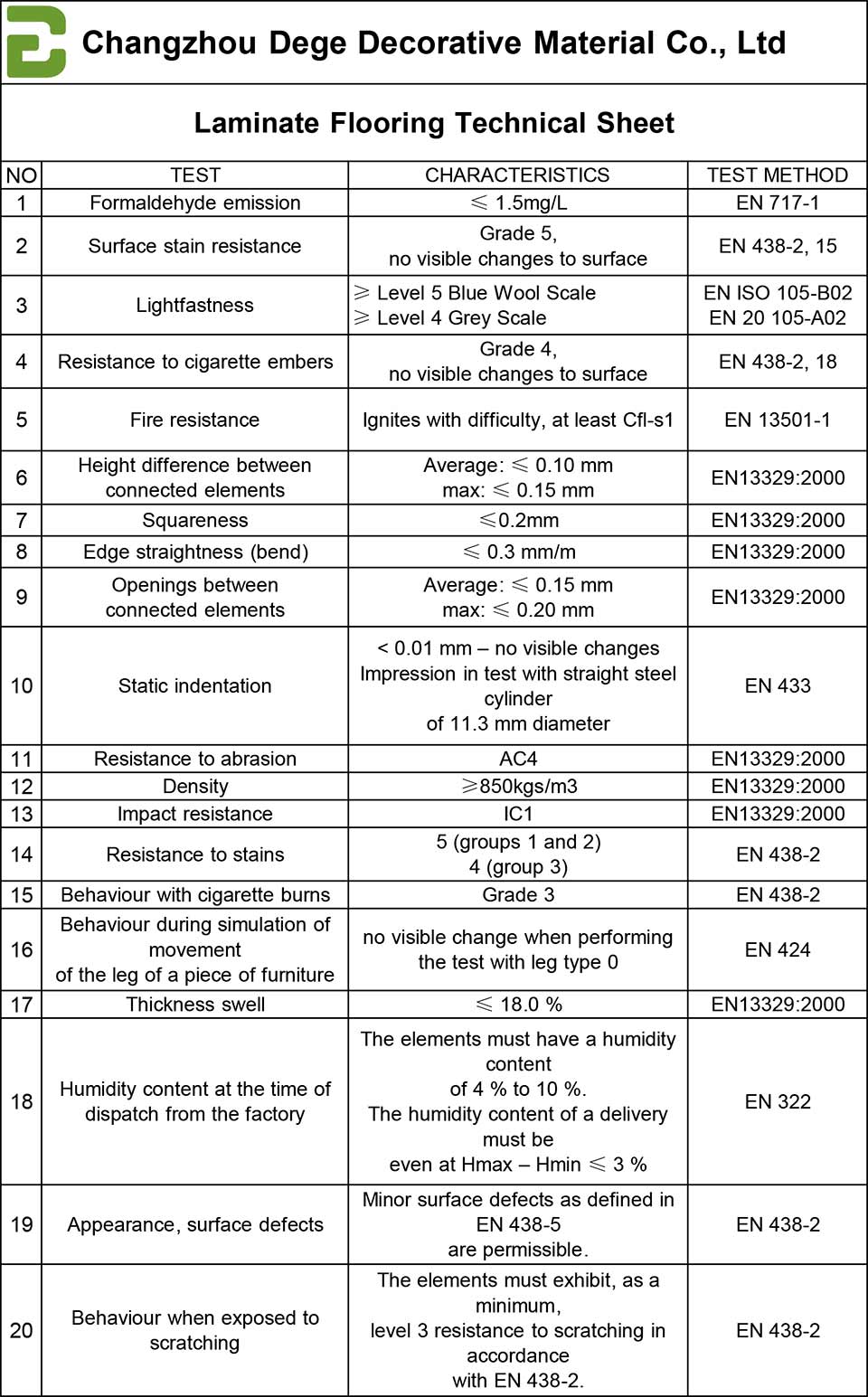

Quality Test

Inspection machine Test

High Glossy Test

Laminate Flooring Package Details

| Packing List | ||||||||

| Size | pcs/ctn | m2/ctn | ctns/pallet | plts/20'cont | ctns/20'cont | kg/ctn | m2/20'cont | kgs/20'cont |

| 1218*198*7mm | 10 | 2.41164 | 70 | 20 | 1400 | 15 | 3376.296 | 21400 |

| 1218*198*8mm | 10 | 2.41164 | 60 | 20 | 1200 | 17.5 | 2893.97 | 21600 |

| 1218*198*8mm | 8 | 1.929312 | 70 | 20 | 1400 | 14 | 2701 | 20000 |

| 1218*198*10mm | 9 | 2.170476 | 55 | 20 | 1100 | 17.9 | 2387.5236 | 20500 |

| 1218*198*10mm | 7 | 1.688148 | 70 | 20 | 1400 | 13.93 | 2363.4072 | 20500 |

| 1218*198*12mm | 8 | 1.929312 | 50 | 20 | 1000 | 20 | 1929.312 | 20600 |

| 1218*198*12mm | 6 | 1.446984 | 65 | 20 | 1300 | 15 | 1881 | 19900 |

| 1215*145*8mm | 12 | 2.1141 | 60 | 20 | 1200 | 15.5 | 2536 | 19000 |

| 1215*145*10mm | 10 | 1.76175 | 65 | 20 | 1300 | 14.5 | 2290.275 | 19500 |

| 1215*145*12mm | 10 | 1.76175 | 52 | 20 | 1040 | 17.5 | 1832 | 18600 |

| 810*130*8mm | 30 | 3.159 | 45 | 20 | 900 | 21 | 2843.1 | 19216 |

| 810*130*10mm | 24 | 2.5272 | 45 | 20 | 900 | 21 | 2274.48 | 19216 |

| 810*130*12mm | 20 | 2.106 | 45 | 20 | 900 | 21 | 1895.4 | 19216 |

| 810*150*8mm | 30 | 3.645 | 40 | 20 | 800 | 24.5 | 2916 | 19608 |

| 810*150*10mm | 24 | 2.916 | 40 | 20 | 800 | 24.5 | 2332.8 | 19608 |

| 810*150*12mm | 20 | 2.43 | 40 | 20 | 800 | 24.5 | 1944 | 19608 |

| 810*103*8mm | 45 | 3.75435 | 32 | 24 | 768 | 27.2 | 2883 | 21289.6 |

| 810*103*12mm | 30 | 2.5029 | 32 | 24 | 768 | 26 | 1922 | 20368 |

| 1220*200*8mm | 8 | 1.952 | 70 | 20 | 1400 | 14.5 | 2732 | 20700 |

| 1220*200*12mm | 6 | 1.464 | 65 | 20 | 1300 | 15 | 1903 | 19900 |

| 1220*170*12mm | 8 | 1.6592 | 60 | 20 | 1200 | 17 | 1991 | 20800 |

Warehouse

Laminate Flooring Container Loading -- Pallet

Warehouse

Laminate Flooring Container Loading -- Carton

1. Teach you how to install laminate flooring by yourself

1. Teach you how to install laminate flooring by yourself

Step 1: Prepare tools

Tools required:

1. Utility knife ; 2. Tape measure ; 3. Pencil ; 4. Hand saw; 5. Spacer ; 6. Hammer ; 7. Rocking rod

Material requirements:

1. Laminate floor 2. Nail 3. Underlayment

Step 2: Preparation before installation

1. Laminate flooring adapts to the environment

Please put the laminate flooring you have purchased in the room to be laid at least 2 days in advance, and give them enough time to adapt to the expansion or contraction of the room temperature and humidity. This prevents bending or other problems after installation.

2. Remove the skirting

Remove the existing skirting line from the wall using a pry bar. Put the part aside and reinstall it. Floating laminate (the kind used in this project) should be installed on a hard, smooth surface, such as vinyl. If the existing floor is damaged, remove it to expose the floor.

Step 3: Start the installation

Installation base materials

1. Installation base

Install the cushion to the floating laminate floor. Remove staples, nails and other debris from the floor. Do not overlap adjacent strips, use a utility knife to chop them as needed. The foam padding can attenuate the sound and help the floor feel more elastic and durable.

2. Planning the layout

To determine the direction of the plank, consider which wall is the longest and the straightest. Avoid narrow strips on the focal wall. The plank in the last row should be at least 2 inches wide. Draw a picture on the 1/4 inch gap of each wall.

Note: If the width of the last row is less than 2 inches, add this width to the width of the whole board and divide it by 2, and cut the first and last rows of boards to this width.

3. Cutting work

Depending on your layout, you may need to tear or cut the first row of boards longitudinally. If using an electric saw, cut the finished side down; if using a hand saw, cut the finished side up. When cutting boards, use clamps to fix the boards.

4. Reserve space

Laminate flooring kits require space to be wedged between the wall and the planks to leave a 1/4 inch expansion joint. Once the base plate is installed, it will not be visible.

5. Shop the first row

Install the tongue side of the plank facing the wall (some manufacturers recommend that you cut off the tongue of the plank facing the wall). Connect one plank to another by connecting tongues and grooves. You may be able to connect the boards tightly by hand, or you may need to use the tie rods and hammers in the installation kit to pull them together, or use tapping blocks to screw the joints together. Cut the last board in the row to length (if it is at least 12 inches long, keep these small pieces).

6. Install other lines

When installing other rows, stagger the seams in adjacent rows by at least 12 inches, as seen on wooden or brick walls. Usually, you can start a new line with scrap from the cut plank to end the previous line.

7. Install the last line

In the last row, you need to slide the plank into place at an angle, and then gently pry it into place with a pry bar. Make sure to leave a 1/4 inch expansion joint between the last row and the wall.

8. Cut the door frame

Don’t try to cut the plank to fit the door frame. Instead, use a side saw to cut the door frame to about 1/16 inch higher than the floor height, so that the board room can slide under the frame. Place a cushioned floor on the floor and close to the shell. Place the door frame saw on the top, and then cut the shell to the desired height.

9. Reinstall other materials

Reinstall the decorative strip. After the plank is in place, use a hammer and nails to reinstall the flooring skirting trim. Then, install the shoe mold on the expansion joint and use the transition strip to connect the laminate to the adjacent surface, such as tile or carpet. Don’t nail it to the floor, but nail it to the decorations and walls.

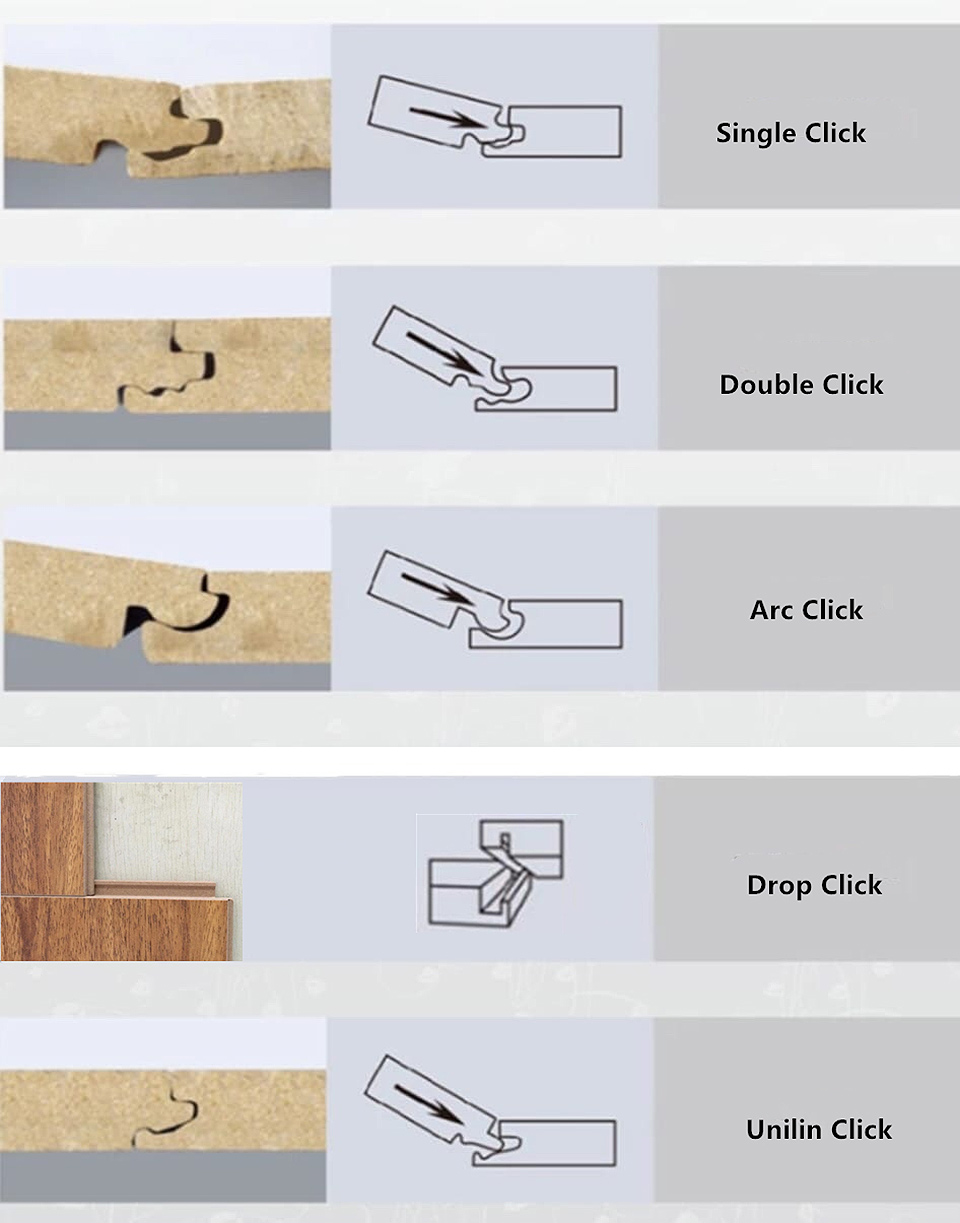

2. Laminate flooring click system

2. Laminate flooring click system

It include different click system, just click shape is different , but same install way.

It name , Single click , Double click ,Arc click , Drop click, Unilin click , Valinge click.

3. Newest Laminate flooring lock system

3. Newest Laminate flooring lock system

12mm Drop click laminate flooring best advantage is Fast Install, Save more 50% install laminate wooden flooring times.