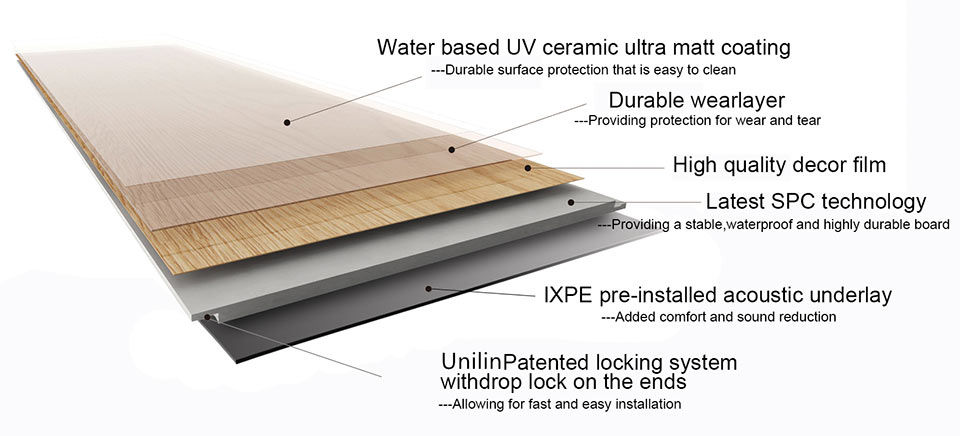

Struktur

Spesifikasi

| SPCSpesifikasi Flooring | |

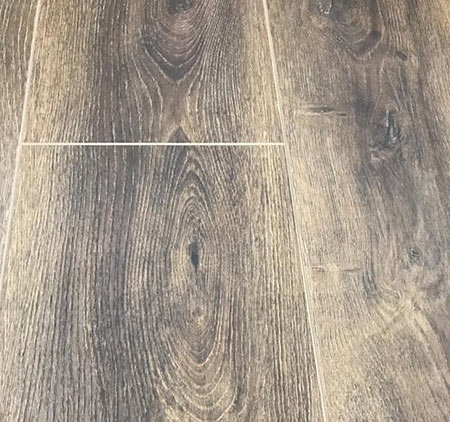

| Gandum Kayu | Oak |

| Kode Warna | DE1173L |

| kekandelan | 3.8mm, 4mm, 4.2mm, 5mm, 5.5mm, 6mm |

| Nganggo Lapisan | Ketebalan 0.2mm, 0.3mm, 0.5mm |

| Ukuran | 910 * 148mm, 1220 * 178mm, 1500 * 228mm, 1800 * 228mm, lsp. |

| lumahing | Kristal, Cahya / Jero Embossed, Kayu Nyata, Handscraped |

| Materi Inti | 100% bahan virgin |

| Klik System | Unilin Klik, Drop Lock (I4F) |

| Perawatan khusus | V-Groove, Kedap Suara EVA/IXPE |

| Cara Instalasi | Ngambang |

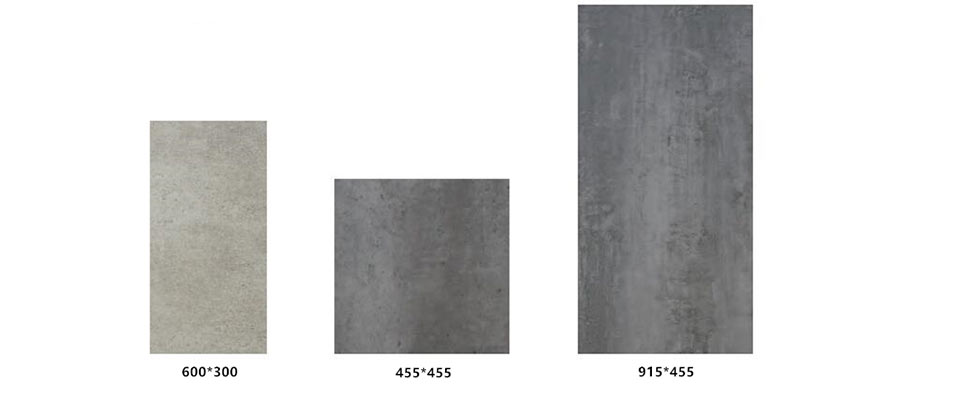

Ukuran

A. Papan Lantai Spc

B. Spc Lantai Genteng

SPC Flooring Backing

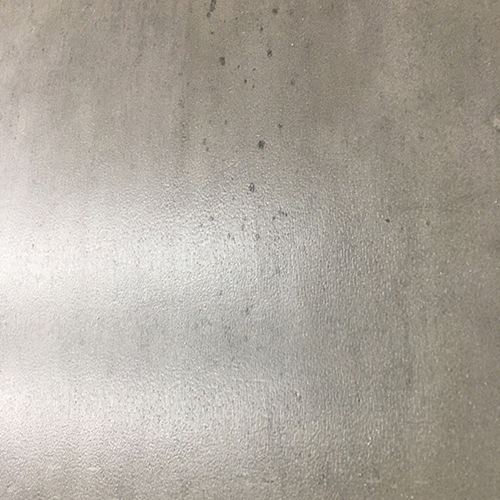

Backing IXPE

Plain EVA Backing

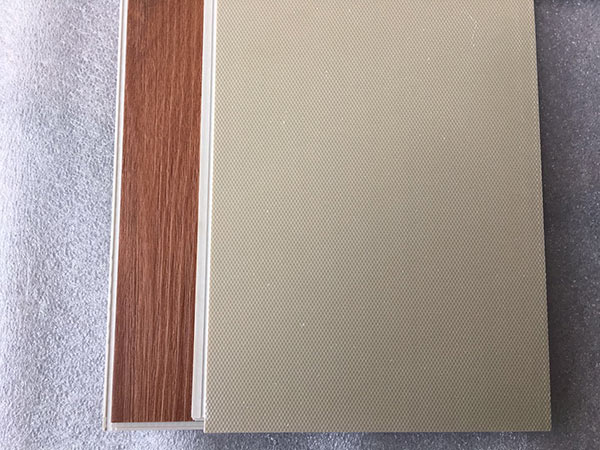

Jinis Rampung

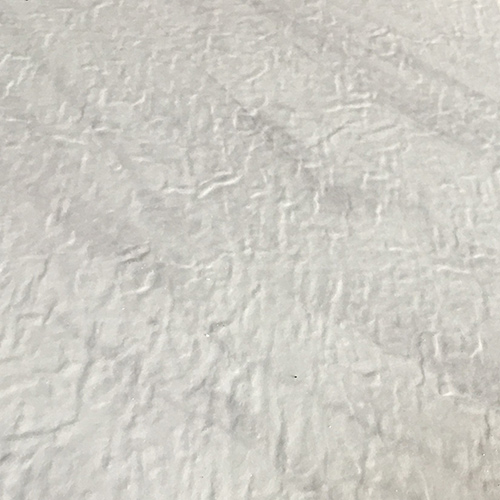

Lumahing Karpet

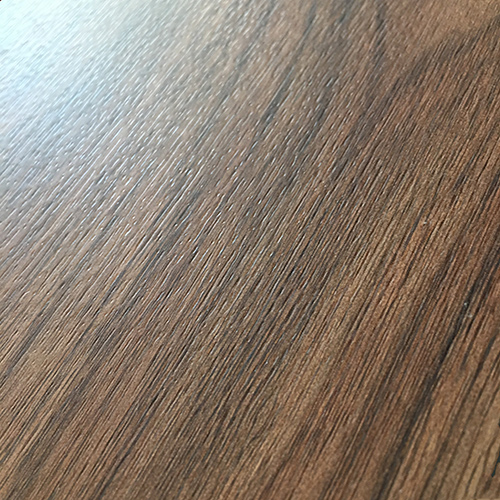

lumahing kristal

Lumahing Embossed jero

Lantai Spc Handscraped

Lumahing Kulit

Cahya Embossed

lumahing marmer

Kayu Nyata

Jinis Ujung Beveled

Micro V-Groove Beveled

V Groove Painted

Apa Bedane Antarane Lantai Spc 100% Virgin lan Lantai Spc Daur Ulang?

Spc Flooring Waterproof Quality Test

Unilin Klik

Unilin Klik 1

Unilin Klik 2

SPC Floor Packing List

| SPC Floor Packing List | |||||||||

| Ukuran | sqm/pc | kg/m2 | pcs/ctn | sqm / ctn | ctn / palet | pallet / 20ft | sqm / 20 ft | ctns / 20ft | Bobot kargo / 20ft |

| 910 × 148 * 3,8 mm | 0.13468 | 7.8 | 16 | 2.15488 | 63ctn / 12pallet, 70ctn / 12pallet | 24 | 3439.190 | 1596 | 27300 |

| 910 × 148 * 4mm | 0.13468 | 8.2 | 15 | 2.02020 | 63ctn / 6pallet, 70ctn / 18pallet | 24 | 3309.088 | 1638 | 27600 |

| 910*148*5mm | 0.13468 | 10.2 | 12 | 1.61616 | 70 | 24 | 2715.149 | 1680 | 28000 |

| 910*148*6mm | 0.13468 | 12.2 | 10 | 1.34680 | 70 | 24 | 2262.624 | 1680 | 28000 |

| 1220*148*4mm | 0.18056 | 8.2 | 12 | 2.16672 | 72ctn / 10pallet, 78ctn / 10pallet | 20 | 3250.080 | 1500 | 27100 |

| 1220*148*5mm | 0.18056 | 10.2 | 10 | 1.80560 | 72 | 20 | 2600.064 | 1440 | 27000 |

| 1220*148*6mm | 0.18056 | 12.2 | 8 | 1.44448 | 78 | 20 | 2253.390 | 1560 | 27900 |

| 1220*178*4mm | 0.21716 | 8.2 | 10 | 2.17160 | 75 | 20 | 3257.400 | 1500 | 27200 |

| 1220*178*5mm | 0.21716 | 10.2 | 8 | 1.73728 | 75 | 20 | 2605.920 | 1500 | 27000 |

| 1220*178*6mm | 0.21716 | 12.2 | 7 | 1.52012 | 70ctn/10pallet, 75ctn/10pallet | 20 | 2204.174 | 1450 | 27300 |

| 600 * 135 * 4mm | 0,0810 | 8.2 | 26 | 2.10600 | 72ctn / 10pallet, 84ctn / 10pallet | 20 | 3285.36 | 1560 | 27400 |

| 600 * 300 * 4mm | 0.1800 | 8.2 | 12 | 2.16000 | 72ctn / 6pallet, 78ctn / 14pallet | 20 | 3291.84 | 1524 | 27400 |

| 1500*225*5mm+2mm IXPE | 0.3375 | 10.6 | 5 | 1.68750 | 64 | 21 | 2268 | 1344 | 24500 |

| 1800 * 225 * 5mm + 1.5mm IXPE | 0,4050 | 10.5 | 5 | 2.025 | 64 | 18 | 2332.8 | 1152 | 24900 |

| Cathetan: Jumlah saben wadhah bisa diatur miturut bobot winates wadhah kanggo port sing beda. | |||||||||

Kaluwihan

Uji Anti Gores Lantai SPC

SPC Floor Test tahan geni

SPC Floor Waterproof Test

Aplikasi

Proyek Lantai Blackbutt Spc ing Australia - 1

Proyek Lantai Gum Spc ing Australia - 2

Proses Proteksi Lantai SPC

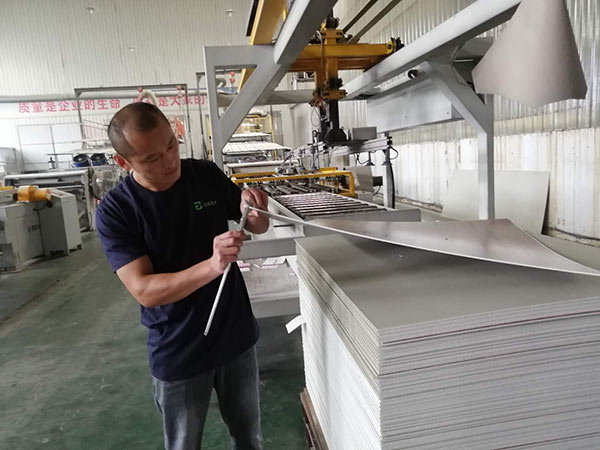

1 Bengkel

4 Dinas Kesehatan Kab

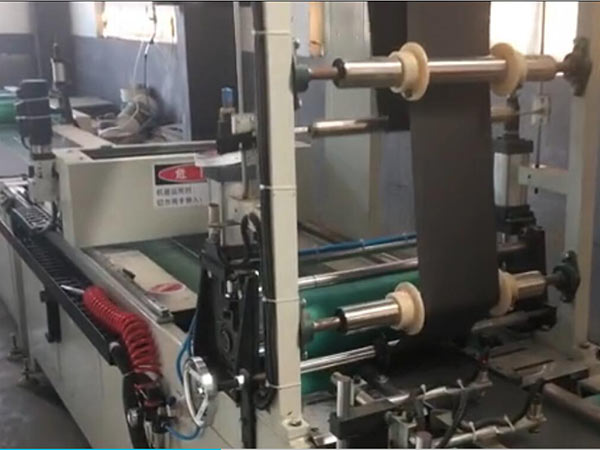

7 SPC Klik Mesin Macking

10 Gudang

2 SPC Coextrusion Machine

5 Tes Mutu SPC

8 Mesin Penambah Busa

11 Loading

3 Mesin UV

6 SPC Cutting Machine / kuwat>

9 Lab

A. Drop Click Spc Flooring Instalasi

A. Drop Click Spc Flooring Instalasi

B. Instalasi Lantai Unilin Klik Spc

B. Instalasi Lantai Unilin Klik Spc

METODE INSTALASI LANTAI SPC

METODE INSTALASI LANTAI SPC

1. Pisanan, nemtokake cara sampeyan pengin jogan mlaku.Biasane kanggo produk plank, jogan nganggo dawa ruangan.Bisa uga ana pangecualian amarga kabeh iku pilihan.

2. Kanggo ngindhari jembaré plank sing sempit utawa dawa papan sing cendhak ing cedhak tembok / lawang, penting kanggo nindakake pra-perencanaan.Nggunakake jembaré kamar, ngetung jumlah papan lengkap sing cocog karo wilayah kasebut lan pira papan sing isih kudu ditutupi papan sebagean.Dibagi spasi sing isih ana kanthi rong kanggo ngetung jembaré papan parsial.Apa padha ing sadawane dawa.

3. Elinga yen baris pisanan saka planks ora perlu dipotong ing jembaré, iku bakal perlu kanggo Cut mati ilat unsupported supaya resik, pinggiran ngalangi menyang tembok.

4. 8mm kesenjangan expansion kudu katahan saka tembok sak instalasi.Iki bakal ngidini spasi kesenjangan ekspansi alam lan kontraksi papan.

5. Papan kudu dipasang saka tengen ngiwa.Saka pojok tengen ndhuwur kamar, sijine plank pisanan ing panggonan supaya loro sirah lan alur jahitan sisih kapapar.

6. Instal plank kapindho ing baris pisanan dening angling basa sisih cendhak menyang alur sisih dawa saka plank pisanan.

7. Kanggo miwiti baris kapindho, Cut a plank sing paling 152,4mm luwih cendhek saka plank pisanan kanthi masang basa sisih dawa menyang alur saka plank ing baris pisanan.

8. Instal plank kapindho ing baris kapindho kanthi masang basa sisih cendhak menyang alur sisih dawa plank pisanan diinstal sadurunge.

9. Nyelarasake plank supaya tip ilat sisih cendhak dipanggonke mung liwat lip alur saka plank ing baris pisanan.

10. Nggunakake pasukan alus lan ing amba 20-30 derajat, push ilat sisih cendhak menyang alur saka plank adjourning dening ngusapake sadawane jahitan sisih dawa.Sampeyan bisa uga kudu ngangkat plank ing sisih tengen rada kanggo ngidini kanggo "ngusapake" tumindak.

11. Papan sing isih ana bisa dipasang ing kamar kanthi nggunakake teknik sing padha.Priksa manawa kesenjangan ekspansi sing dibutuhake dijaga ing kabeh bagean vertikal sing tetep (kayata tembok, lawang, lemari, lsp).

12. Ing planks bisa Cut gampang karo piso sarana, mung Skor ndhuwur plank lan sworo seru plank ing loro.

| Ciri khas | Spesifikasi Tes lan Hasil |

| Ukuran (ing inci) | 6×36;6×48;7×48;8×48;9×48;12×24;12×48;12×36;18×36 |

| kekandelan | 3.8mm, 4.0mm, 4.5mm, 5.0mm, 5.5mm, 6.0mm |

| Lampiran / Backing | 1.5mm utawa 2.0mm IXPE lan EVA |

| Squareness | ASTM F2055 - Pass - 0,010 ing. maks |

| Ukuran lan Toleransi | ASTM F2055 - Pass - +0.016 ing saben sikil linear |

| kekandelan | ASTM F386 - Pass - Nominal +0.005 in. |

| Fleksibilitas | ASTM F137 - Pass - ≤1.0 in., ora retak utawa pecah |

| Stabilitas dimensi | ASTM F2199 - Pass - ≤ 0,024 in saben sikil linear |

| Anane / Ora Ana Metal Heavy | EN 71-3 C — Meet Spec.(Timbal, Antimon, Arsenik, Barium, Kadmium, Kromium, Merkuri lan Selenium). |

| Ketahanan Generasi Kumelun | EN ISO 9239-1 (Fluks Kritis) Asil 9.1 |

| Resistance Generasi Kumelun, Mode Non-Flaming | EN ISO |

| Kebakaran | ASTM E648- Kelas 1 Rating |

| Sisa Indentasi | ASTM F1914 - Lulus - Rata-rata kurang saka 8% |

| Watesan beban statis | ASTM-F-970 Pass 1000psi |

| Requirements kanggo Wear Group pr | EN 660-1 Kekandelan Mundhut 0.30 |

| Tahan Slip | ASTM D2047 – Lulus – > 0,6 Basah, 0,6 Kering |

| Resistance kanggo cahya | ASTM F1515 - Lulus - ∧E ≤ 8 |

| Resistance kanggo Panas | ASTM F1514 - Lulus - ∧E ≤ 8 |

| Perilaku Listrik (ESD) | EN 1815: 1997 2,0 kV nalika diuji ing 23 C+1 C |

| Underfloor Pemanasan | Cocog kanggo nginstal pemanasan ing ngisor lantai. |

| Curling Sawise Exposure kanggo Panas | EN 434 < 2mm lulus |

| Konten Vinyl Daur Ulang | Kira-kira 40% |

| Daur ulang | Bisa didaur ulang |

| Garansi produk | Komersial 10 Taun & Perumahan 15 Taun |

| Floorscore Certified | Sertifikat Diwenehake Yen Panyuwunan |