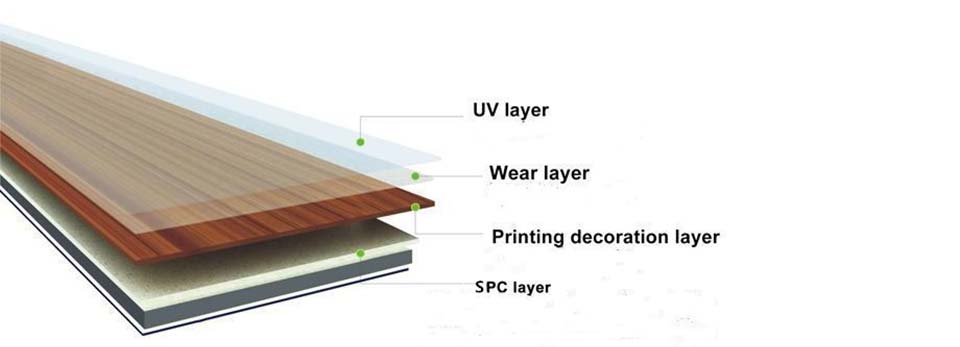

Struktur

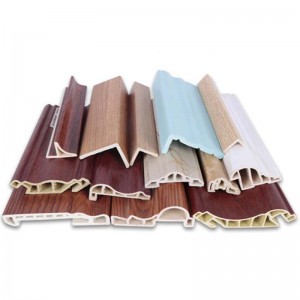

Spesifikasi

| Spesifikasi | |||

| Bahan Model | WPC | ||

| Jeneng Model | WPC SKIRTING, WPC REDUCER, WPC TMOLDING, WPC CONCAVE LINE lan SCOTIA, WPC L END CAPE, WPC FLUSH STAIR NOSE | ||

| Ukuran | T-MOLDING: 2400*38*7 MM REDUCER: 2400*43*10 MM END CAP: 2400*35*10 MM Babak seprapat: 2400 * 28 * 16 MM Irung tangga: 2400 * 54 * 18 MM FLUSH STAIR NOSE: 2400*72*25MM FLUSH STAIR NOSE: 2400*110*25MM | ||

| MOQ | 100PCS | ||

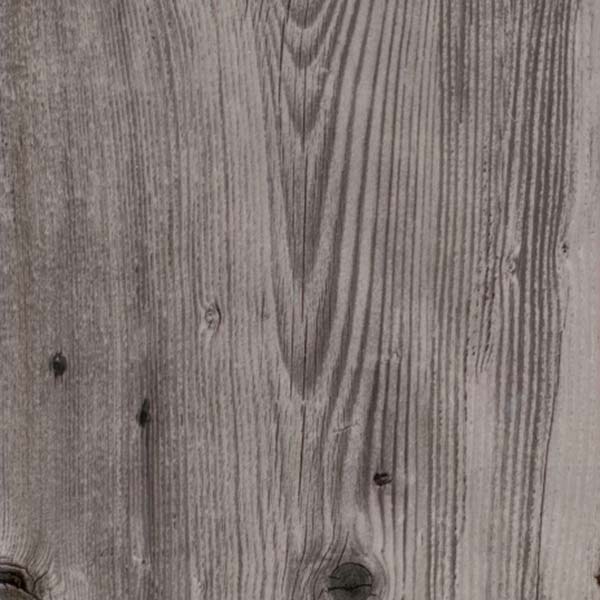

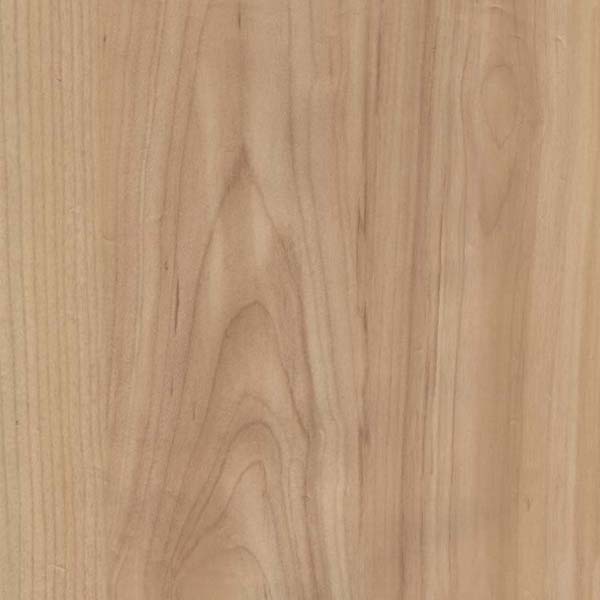

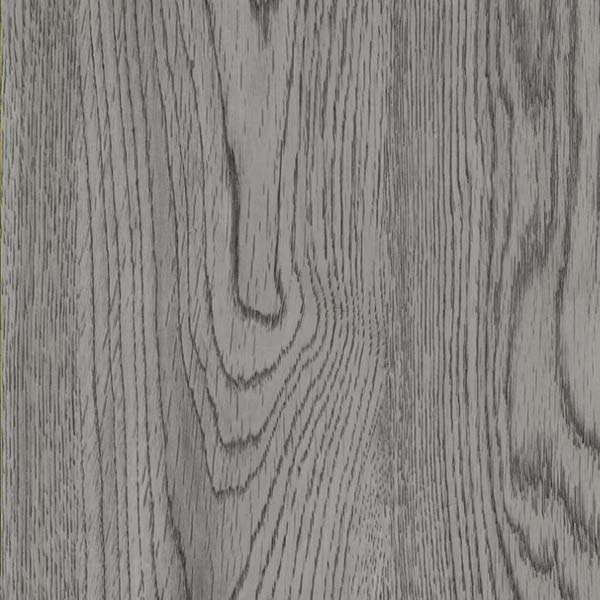

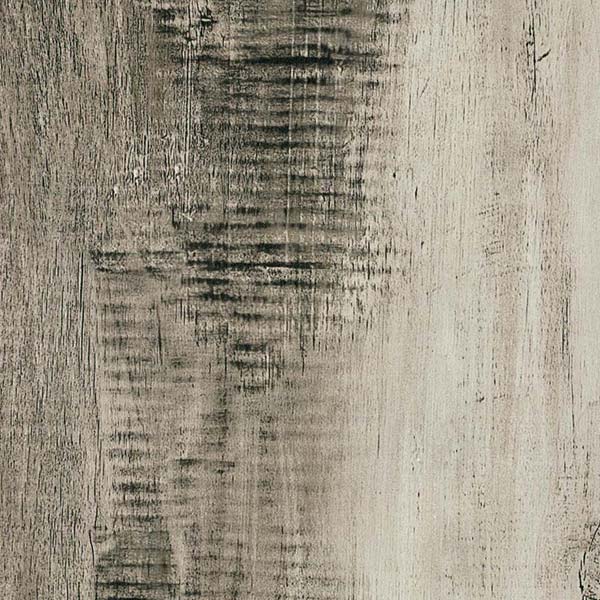

| warna | OAK, CHERRY, WALNUT, ABU, BEECH, PINE, Blackbutt, Gumm Bintik | ||

| Paket | Inner packing: tas plastik. | ||

| Kemasan njaba: palet ditutupi kayu lapis utawa karton lan banjur baja kanggo kekuatan | |||

| utawa selaras | |||

| Wektu Pangiriman | 20 dina | ||

| Sertifikat | CESGSISO9001 | ||

| Aplikasi | lantai laminate, lantai pvc, lantai vinyl spc, lantai kayu dll | ||

| Fitur | Waterproof, Fireproof, Soundproof, Wear Resistance | ||

Gambar Nyata Papan Tangga

Big Wpc Stair Molding

| Bahan | WPC |

| werna-werna | OAK, WALNUT, CHERRY, MAPLE, TEAK, AWE lan sapanunggalane. |

| Ketebalan produk | <=6 MM (0,24 in.)utawa> 6 MM (0.24 in.) |

| Ukuran Produk | 2200X300X24MM (86.6*11.81*0.94in.) |

| Ukuran Karton | 2220x155x95MM (87.4*6.1*3.74in.) |

| Packing Karton | 10 PCS / CTN;8200PCS / 20GP |

| Pallet Packing | 5280PCS / 20GP |

| Bobot/Katon | 50KGS (110.2lbs) |

| Panggonan Asal | Cina |

| Spesifikasi | Kita ukuran standar utawa ukuran Customized |

| profil | Profil standar utawa profil sing disesuaikan |

| MOQ | 150-200 PCS warna tunggal, 700-800 PCS multi-warna |

| Paket | pallets ditutupi karo plywood, karton lan film babagan |

| Pelabuhan | Shanghai |

| wektu pangiriman | <= 1000pcs 5-7 dina, 1000-5000pcs 10-15Dina |

| Fitur | Lumahing Water-Proof, Anti Gores, lsp |

| Produk relatif | Skirting, baseboard, Reducer, End molding, stair nosing, quarter round molding dll. |

| Aplikasi | lantai laminate, lantai pvc, lantai vinyl spc, lantai kayu dll |

Aplikasi saka Papan Tangga

Paket lan Loading

FLUSH-STAIR-wpc-NOSE

FLUSH-STAIR-wpc-NOSE  shaoe

shaoe  wpc-END-CAP

wpc-END-CAP  wpc-QUARTER-ROUND

wpc-QUARTER-ROUND  wpc-REDUCER

wpc-REDUCER  wpc-SCOTIA

wpc-SCOTIA  wpc-SKIRTING

wpc-SKIRTING  wpc-T-MOULDING

wpc-T-MOULDING wpc-OVERLAP-STAIR-NOSE

wpc-OVERLAP-STAIR-NOSE

Apa WPC FLUSH STAIR NOSE?

Apa WPC FLUSH STAIR NOSE?

Iki minangka salah sawijining jinis bahan anyar kanggo FLUSH STAIR NOSE.Struktur kasebut yaiku warna wpc + film kertas dekoratif. WPC, sing diarani Komposit Plastik Kayu, minangka bahan komposit sing digawe kanthi nambahake aditif kimia lan pengisi cilik ing plastik lan serat kayu lan diproses kanthi peralatan pencampur khusus.WPC nduweni perlindungan lingkungan sing dhuwur, bebas polusi, panggunaan sing bisa didaur ulang.Nemen nyuda panggunaan kayu, lan karakteristik anti banyu lan kelembapan-bukti bisa nggawe WPC digunakake ing lingkungan sing produk kayu tradisional ora bisa digunakake.

Babagan film kertas hiasan diprodhuksi dening liwat printing, supaya bisa rampung padha karo jogan .Saiki DEGE Brand bisa nyuplai oak, beech, walnut, ceri, jati, awu, werna birch kanggo stairnose.

WPC FLUSH STAIR NOSE VS MDF STAIR NOSE

WPC FLUSH STAIR NOSE VS MDF STAIR NOSE

1).100% anti banyu lan supaya bisa digunakake ing wilayah udan;

2).Ramah lingkungan, Formaldehida kurang, Ora ana ambune;

3) .Super resistance nyandhang: WPC FLUSH STAIR NOSE lumahing wis khusus transparent nyandhang lapisan karo teknologi dhuwur lan iku paling apik ing antarane kabeh aksesoris jogan.aksesoris wpc dadi luwih populer.

4).Awet, asam lan alkali tahan, antijamur, anti-statis;

5).Fireproof lan Flame-retardant: Kapadhetan flammability lan kumelun tekan standar B1 nasional lan iku karo resistance semangat super, nambah faktor safety urip manungsa;

6).Super anti-slip: WPC Stair nose Wear Layer nduweni resistensi slip khusus;

7).Swara-nresep lan anti-gangguan: Wpc Aksesoris wis swara apik nresep fungsi sing jubin liyane ora bisa dibandhingake lan panyerepan swara nganti 20 decibel.Dadi papan sing mbutuhake lingkungan sing sepi kayata bangsal rumah sakit, perpustakaan, ruang kuliah, teater milih.

8).Instalasi Cepet lan Gampang: Gampang banget lan cepet nginstal aksesoris wpc lan tanpa mortir semen lan yen lemah rata, bisa langsung dipasang lan bisa digunakake sawise 24 jam.

9).Iku luwih stabil tinimbang mdf FLUSH STAIR NOSE lan tingkat ekspansi kira-kira 0,2%.

| No | Ciri khas | Target Teknologi | Tetembungane | |||||

| 1 | Penampilan | Ora ana chipping, retak, tekstur visual, delaminasi, gelembung, embossing cethek, goresan, rereget, potongan miskin, lsp | EN649 | |||||

| 2 | Ukuran mm (23 ℃) | dawa | ± 0,20 mm | EN427 | ||||

| jembar | ± 0,10 mm | EN427 | ||||||

| kekandelan | +0,13 mm, -0,10 mm | EN428 | ||||||

| Range Ketebalan | ≤0,15 mm | EN428 | ||||||

| Ketebalan wearlay | ± 0,02 mm | EN429 | ||||||

| 3 | Ketebalan mm | ≤ 0,15 | EN427 | |||||

| 4 | Kroncong mm | ≤ 0,15 | EN427 | |||||

| 5 | Sudut Potong Microbevel | 8-15 derajat | ||||||

| Microbevel Cut ambane | 0,60 – 1,5 mm | |||||||

| 6 | Stabilitas dimensi sawise kena panas | ≤ 0,12% | EN434 | |||||

| 7 | Curling sawise paparan panas | WPC: ≤0.2(70℃/6Jam) | EN434 | |||||

| SPC: ≤0.2(80℃/6Hr) | ||||||||

| 8 | Tingkat gloss | nilai nominal ± 1,5 | Lightmeter | |||||

| 9 | Abrasion Taber - Minimal | 0,5 mm nyandhang lay | ≥5000 siklus Rata-rata | EN660 | ||||

| 10 | Uv | 8~12g/m2 | ||||||

| 11 | ≥9N | |||||||

| KINERJA SCRATCH UV | SCLEROMETER | |||||||

| 12 | Kinerja anti-noda | yodium | 3 | Diowahi ASTM 92 | ||||

| Minyak Coklat | 0 | |||||||

| Mustard | 0 | |||||||

| Shope Polandia | 2 | |||||||

| Biru Sharpie | 1 | |||||||

| 13 | Penentuan keluwesan | ora retak | EN435 | |||||

| 14 | Ketahanan Peel | dawa | ≥62.5N/5cm | EN431(62.5N/5cm,100mm/s) | ||||

| ambane | ≥62.5N/5cm | |||||||

| 15 | Sisa indentasi (rata-rata) mm | ≤0.15 | EN433 | |||||

| 16 | Fastness warna: | ≥7 | ISO 105-B2: 2002 | |||||

| 17 | Kekuwatan Ngunci | fsmax ≥2.5N/mm | ISO 24344 | |||||

-

Garis Dekoratif Aluminium Logam kanggo Panel Dinding ...

-

Spc Molding kanggo SPC lan WPC Flooring

-

EPE, EVE, IXPE Underlayment kanggo Laminasi, SPC...

-

Garis Dekoratif Wpc kanggo Kabeh Jenis Panel Dinding a...

-

Molding Mdf Kualitas apik kanggo Fl Kayu Laminasi ...

-

Aluminium Molding, Reducer, T-molidng kanggo Kabeh ...