Nhazi

Nkọwapụta

| Nkọwapụta | |||

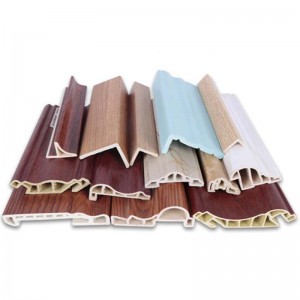

| Ihe Nlereanya | WPC | ||

| Aha Nlereanya | WPC SKIRTING, WPC REDUCER, WPC TMOLDING, WPC CONCAVE LINE na SCOTIA, WPC L END CAPE, WPC FLUSH stair imi | ||

| Nha | T-MOLDING:2400*38*7MM Mbelata:2400*43*10MM Nkwụsị ngwụcha: 2400*35*10MM Gburugburu nkeji iri na ise:2400*28*16MM Imi steepụ:2400*54*18MM Imi steepụ steepụ: 2400*72*25MM Imi steepụ steepụ: 2400*110*25MM | ||

| MOQ | 100 PCS | ||

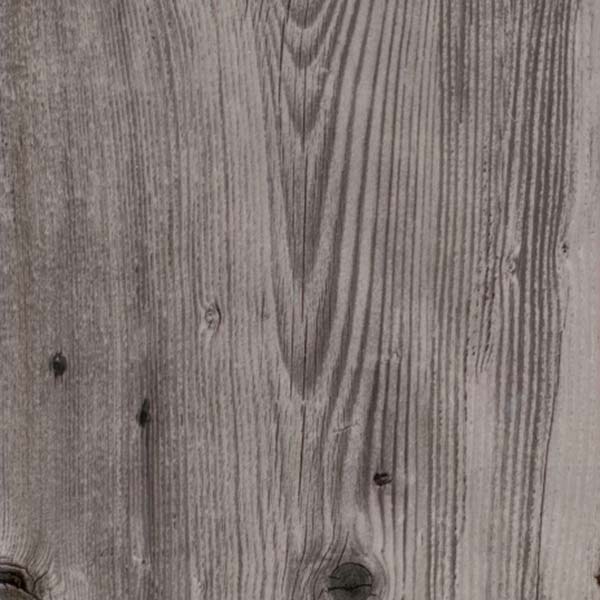

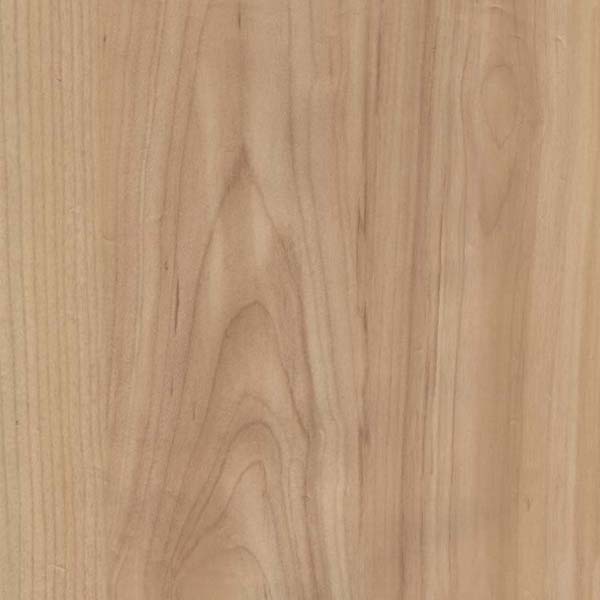

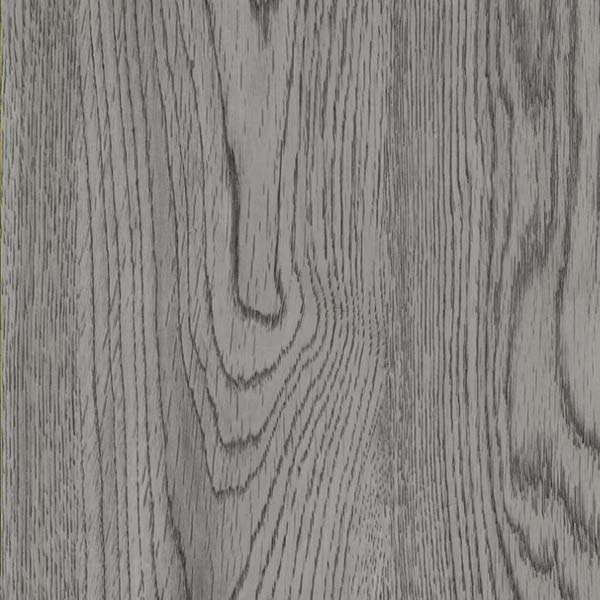

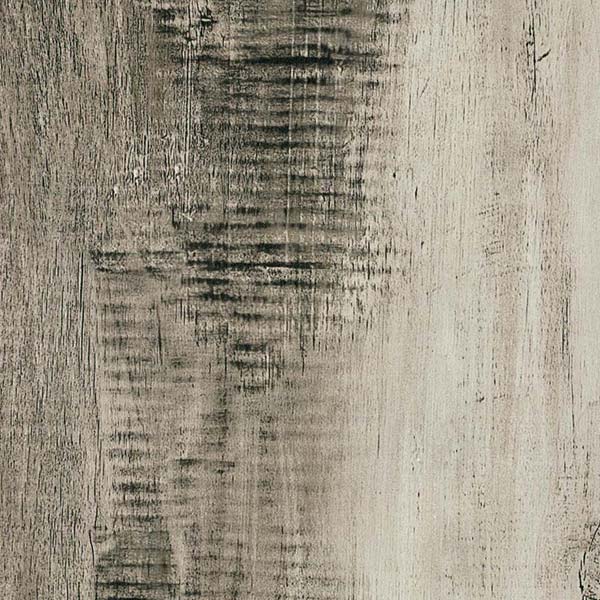

| Agba | Oak, cherry, ukpa, uyi, beech, PINE, Blackbutt, Spotted Gumm | ||

| ngwugwu | Nkwakọ ngwaahịa dị n'ime: akpa rọba. | ||

| Nkwakọ ngwaahịa dị n'èzí: a na-eji plywood ma ọ bụ katọn kpuchie pallets wee jiri ígwè mee ike | |||

| ma ọ bụ ahaziri | |||

| Oge Mbuga ozi | Ụbọchị 20 | ||

| Asambodo | CESGSISO9001 | ||

| Ngwa | laminate flooring, pvc flooring, spc vinyl flooring, osisi ala wdg | ||

| Njirimara | Igwe anaghị egbochi mmiri, ọkụ anaghị egbochi ụda, ihe mgbochi iyi | ||

Foto dị adị nke bọọdụ steepụ

Nnukwu Wpc Stair Molding

| Akụrụngwa | WPC |

| Agba | Oak, ukpa, cherry, MAAPLE, TEak, ash na ndị ọzọ. |

| Ọkpụrụkpụ ngwaahịa | <= 6MM (0.24in.)ma ọ bụ> 6MM (0.24in.) |

| Nha Roduct | 2200X300X24MM (86.6*11.81*0.94in.) |

| Nha katọn | 2220x155x95MM (87.4*6.1*3.74in.) |

| Nkwakọ ngwaahịa katọn | 10PCS/CTN;8200PCS/20GP |

| Nkwakọ ngwaahịa pallet | 5280PCS/20GP |

| Ibu/Caton | 50KGS (110.2 lbs) |

| Ebe Mmalite | China |

| Nkọwapụta | Ogo ọkọlọtọ anyị ma ọ bụ nha ahaziri ahazi |

| Profaịlụ | Profaịlụ ọkọlọtọ anyị ma ọ bụ profaịlụ ahaziri ahazi |

| MOQ | 150-200 PCS otu agba, 700-800 PCS multi-agba |

| ngwugwu | A na-ekpuchi pallets na plywood, katọn na ihe nkiri gbatịa |

| Port | Shanghai |

| Oge Mbuga ozi | <=1000pcs 5-7 ụbọchị,1000-5000pcs 10-15days |

| Njirimara | Ngosipụta mmiri dị n'elu, mgbochi mkpocha, wdg |

| Ngwaahịa ndị ikwu | Skirting, baseboard, Reducer, Ọgwụgwụ ịkpụzi, steepụ nosing, nkeji iri na ise gburugburu ịkpụzi wdg. |

| Ngwa | laminate flooring, pvc flooring, spc vinyl flooring, osisi ala wdg |

Ngwa nke bọọdụ steepụ

Ngwugwu na Nbudata

FLUSH-staIR-wpc-Imi

FLUSH-staIR-wpc-Imi  shaee

shaee  wpc- END-CAP

wpc- END-CAP  wpc-QUARTER-gburugburu

wpc-QUARTER-gburugburu  wpc-REDUCER

wpc-REDUCER  wpc-SCOTIA

wpc-SCOTIA  wpc-SKIRTING

wpc-SKIRTING  wpc-T-MULDING

wpc-T-MULDING wpc-N'AKWỤKWỌ-staIR-Imi

wpc-N'AKWỤKWỌ-staIR-Imi

Kedu ihe bụ WPC FLUSH stair imi?

Kedu ihe bụ WPC FLUSH stair imi?

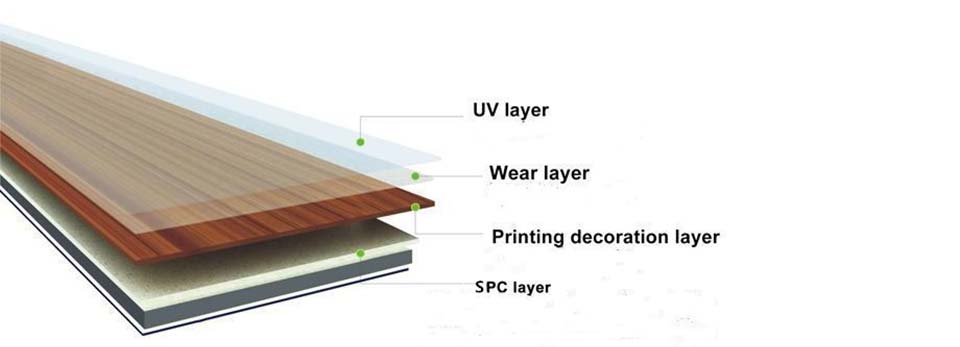

Ọ bụ otu ụdị ọhụrụ ihe eji eme FLUSH stair imi.Ihe owuwu ahụ bụ wpc agba + ihe nkiri akwụkwọ eji achọ mma.WPC, nke a na-akpọ Osisi Plastic Composite, bụ ụdị ihe eji eme ihe na-eme ka ọ bụrụ ihe na-eme ka ọ bụrụ ihe na-emepụta ihe na-emepụta ihe na-emepụta ihe na-emepụta ihe na-emepụta ihe na-emepụta ihe na-emepụta ihe na-emepụta ihe na-emepụta ihe na-emepụta ihe na-emepụta ihe na-emepụta ihe na-emepụta ihe na-emepụta ihe na-emepụta ihe na-emepụta ihe na-emepụta ihe na-emepụta ihe na-emepụta ihe na-emepụta ihe na-emepụta ihe na-emepụta ihe na-emepụta ihe na-emepụta ihe na-emepụta ihe na-emepụta ihe na-emepụta ihe na-emepụta ihe na-emepụta ihe na-emepụta ihe na-emepụta ihe na-emepụta ihe na-emepụta ihe na-emepụta ihe na-emepụta ihe na-emepụta ihe na-emepụta ihe na-emepụta ihe na-edozi ahụ site na ngwá ọrụ ngwakọta pụrụ iche.WPC nwere nnukwu nchekwa gburugburu ebe obibi, enweghị mmetọ, ojiji enwere ike ịmegharị ya.Nke ukwuu na-ebelata ojiji nke osisi, na njirimara nke waterproof na mmiri-àmà nwere ike ime ka WPC eji na gburugburu ebe obibi nke omenala osisi ngwaahịa na-enweghị ike iji.

Banyere ihe nkiri akwụkwọ eji achọ mma na-emepụta site na ibipụta ya, ya mere enwere ike ime ya na ala ala gị. Ugbu a DEGE Brand nwere ike ịnye osisi oak, beech, ukpa, cherry, teak, ash, agba birch maka steepụ.

WPC FLUSH steepụ imi VS MDF steepụ imi

WPC FLUSH steepụ imi VS MDF steepụ imi

1).100% enweghị mmiri na ya mere enwere ike iji ya na mpaghara mmiri;

2).gburugburu-enyi na enyi, formaldehyde obere, enweghị isi;

3) .Super iyi eguzogide: WPC FLUSH steepụ imi elu nwere pụrụ iche transperent eyi oyi akwa na elu technology na ọ bụ ihe kasị mma n'etiti niile nke flooring ngwa.Ngwa wpc na-aghọwanye ewu ewu.

4).Na-adịgide adịgide, acid na alkali na-eguzogide ọgwụ, antifungal, mgbochi static;

5).Ọkụ na-egbochi ọkụ na ọkụ: Ọkụ ọkụ ya na njupụta anwụrụ ọkụ ruru ọkọlọtọ B1 nke mba yana ọ na-enwe nnukwu ọkụ ọkụ, na-abawanye ihe nchekwa nke ndụ mmadụ;

6).Super mgbochi-slip: WPC steepụ imi Wear Layer nwere nguzogide ntupu pụrụ iche;

7).Mbelata ụda na mgbochi mkpọtụ: Ngwa Wpc nwere ọrụ nnabata ụda dị mma nke na enweghị ike ijikọ ala ndị ọzọ yana nnabata ụda ya ruru decibel 20.Ya mere, ebe ndị chọrọ ebe dị jụụ dị ka ngalaba ụlọ ọgwụ, ụlọ akwụkwọ ọbá akwụkwọ, ụlọ okwu nkuzi, ụlọ ihe nkiri na-ahọrọ ya.

8).Ntinye ngwa ngwa na ngwa ngwa: Ọ dị mfe na ngwa ngwa iji wụnye ngwa wpc na enweghị ngwa ngwa ciment ma ọ bụrụ na ala dị larịị, enwere ike itinye ya ozugbo ma nwee ike iji ya mgbe awa 24 gachara.

9).Ọ kwụsiri ike karịa mdf FLUSH STAIR ISI na ọnụego mgbasawanye ya bụ ihe dịka 0.2%.

| No | Njirimara | Ebumnuche teknụzụ | Okwu | |||||

| 1 | Ọdịdị | Enweghị chipping, cracking, visual texture, delamination, afụ, na-emighị emi embossing, ọkọ, unyi, adịghị mma ịkpụ, wdg | EN649 | |||||

| 2 | Size mm (23 ℃) | Ogologo | ± 0.20mm | EN427 | ||||

| Obosara | ± 0.10mm | EN427 | ||||||

| Ọkpụrụkpụ | + 0.13mm, -0.10mm | EN428 | ||||||

| Oke oke | ≤0.15 mm | EN428 | ||||||

| wearlay Ọkpụrụkpụ | ± 0.02 mm | EN429 | ||||||

| 3 | Okirikiri mm | ≤ 0.15 | EN427 | |||||

| 4 | Crook mm | ≤ 0.15 | EN427 | |||||

| 5 | Microbevel Cut Angle | 8-15 degrees | ||||||

| Microbevel Cut Omimi | 0.60-1.5 mm | |||||||

| 6 | Nkwụsi ike akụkụ mgbe ikpughe ọkụ | ≤0.12% | EN434 | |||||

| 7 | Curling mgbe ikpughe na okpomọkụ | WPC: ≤0.2 (70 ℃ / 6Hr) | EN434 | |||||

| SPC: ≤0.2 (80 ℃ / 6Hr) | ||||||||

| 8 | Ọkwa gloss | ọnụ ala ± 1.5 | Igwe ọkụ ọkụ | |||||

| 9 | Taber abrasion - kacha nta | 0.5mm okpu okpu | ≥5000 okirikiri nkezi | EN660 | ||||

| 10 | Uv | 8 ~ 12g/m2 | ||||||

| 11 | ≥9N | |||||||

| Arụmọrụ Scratch UV | SCLEROMETER | |||||||

| 12 | Arụmọrụ mgbochi ntụpọ | Iodine | 3 | Emegharịrị ASTM 92 | ||||

| Mmanụ Brown | 0 | |||||||

| Mọstad | 0 | |||||||

| Ụlọ ahịa Polish | 2 | |||||||

| Blue Sharpie | 1 | |||||||

| 13 | Mkpebi nke mgbanwe | enweghị mgbape | EN435 | |||||

| 14 | Peel Nguzogide | Ogologo | ≥62.5N/5cm | EN431 (62.5N / 5cm, 100mm / s) | ||||

| obosara | ≥62.5N/5cm | |||||||

| 15 | Ntinye ihe fọdụrụ (nkezi) mm | ≤0.15 | EN433 | |||||

| 16 | Ngwa ngwa agba: | ≥7 | ISO105-B2: 2002 | |||||

| 17 | Ike mkpọchi | fsmax ≥2 .5N/mm | ISO 24344 | |||||