Video

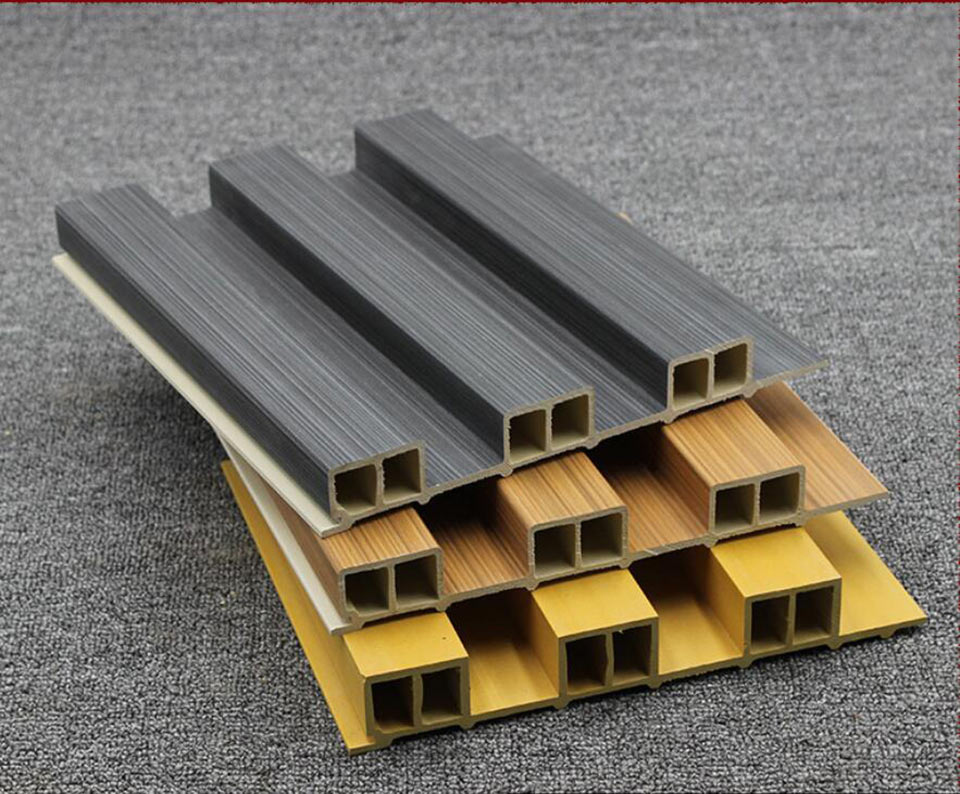

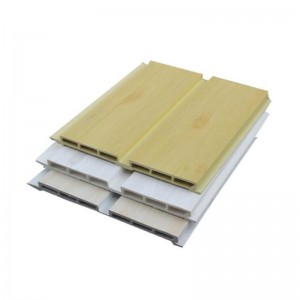

Sab hauv Phab Ntsa Vaj Huam Sib Luag yog ib hom Nws yog cov khoom siv kho kom zoo nkauj phab ntsa, cov khoom tseem ceeb yog cov khoom siv ntoo-yas (wpc), cov khoom siv tshiab rau ib puag ncig.ntoo xim, cov qauv ntaub, cov xim pob zeb muaj rau xaiv, thiab nws muaj qhov zoo ntawm cov dej tsis zoo, cov kab mob, ntsiag to, yooj yim nruab, thiab lwm yam. Siv dav hauv kev txhim kho tsev thiab chaw lag luam.

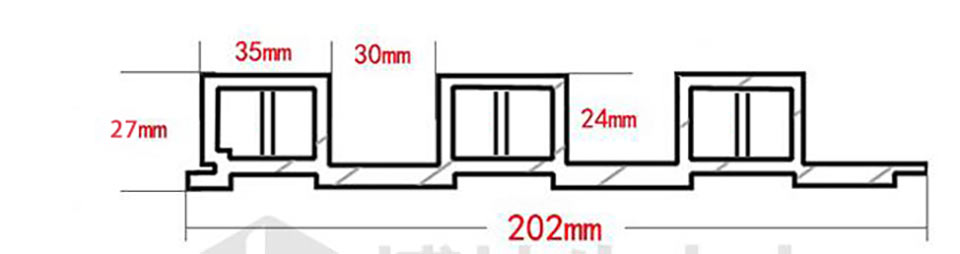

Sab hauv vaj huam sib luag Parameter

| Cov khoom npe | Sab hauv phab ntsa vaj huam sib luag, |

| Qauv | PVC Phab ntsa Cladding |

| Loj | 2900 * 202 * 27 hli |

| Nto | Pvc Zaj duab xis Laminated |

| Khoom siv | WPC: Ntoo Pvc Composite.Kev sib xyaw ntawm cov hmoov ntoo thiab poly ethylene nrog rau qhov sib ntxiv ntawm qee yam additives |

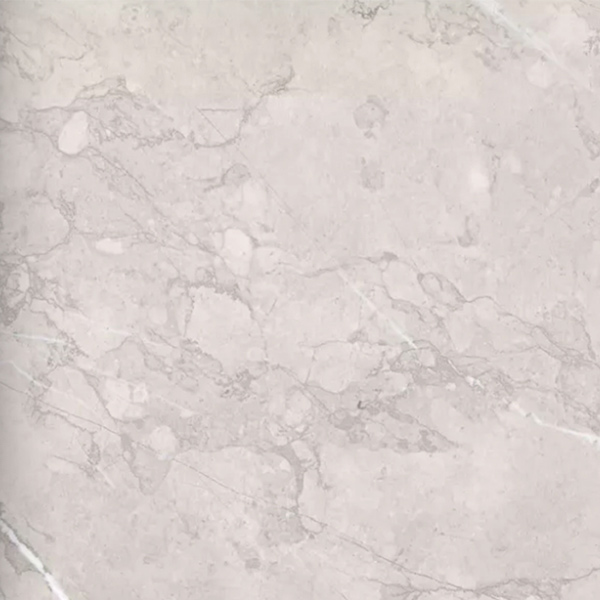

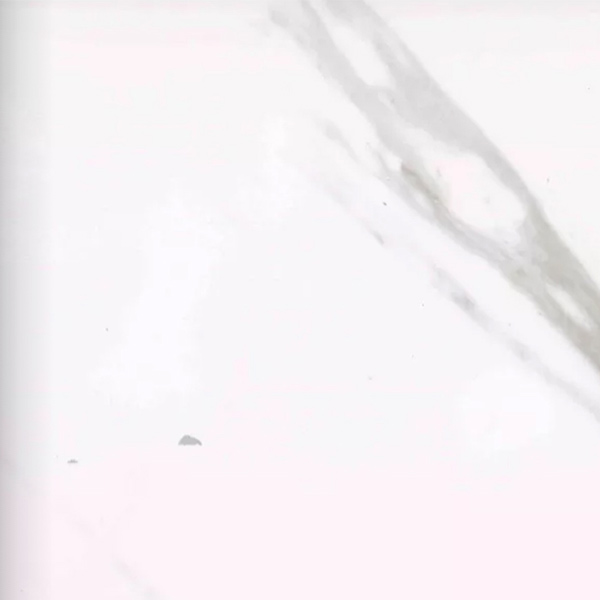

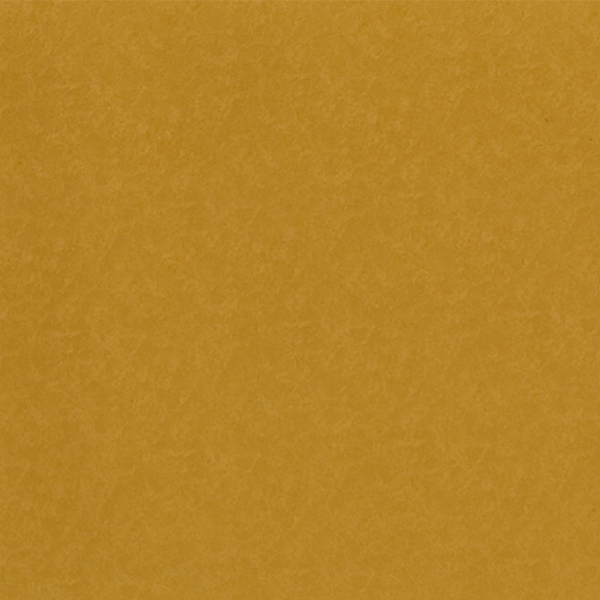

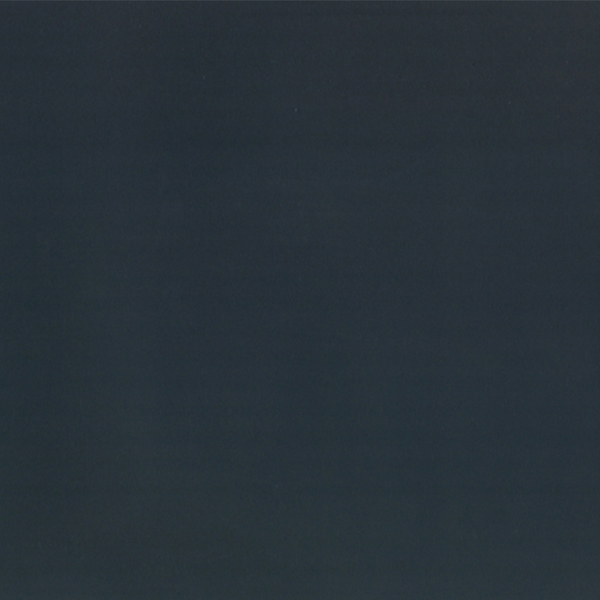

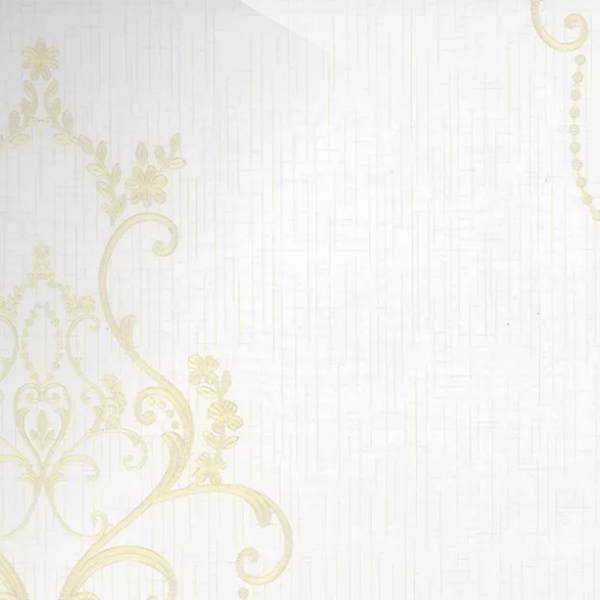

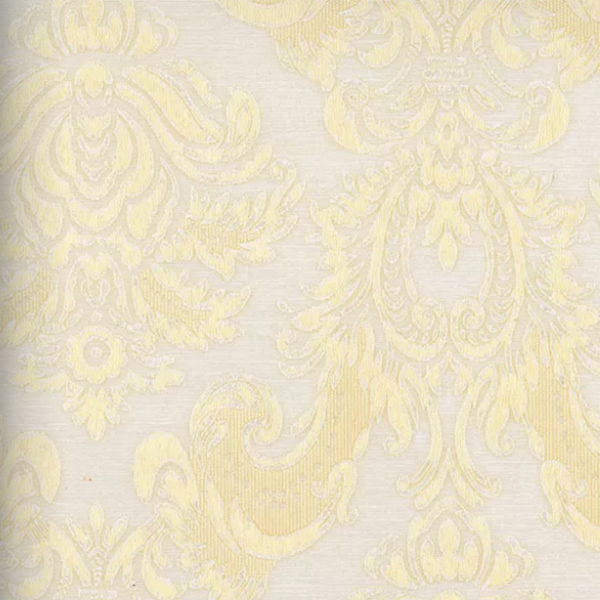

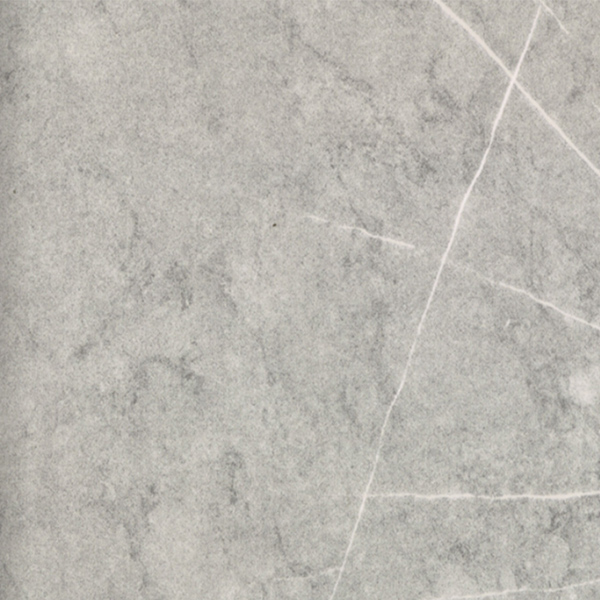

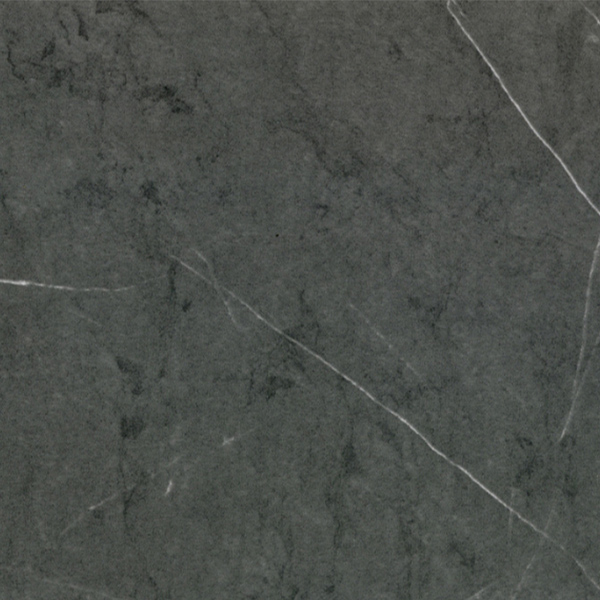

| Xim | Oak, Kub, Mahogany, Teak, Cedar, Liab, Classic Grey, Dub Walnut |

| Yam tsawg kawg nkaus | Tag nrho 20ft Thawv, 500 meters ib Xim |

| Pob | Standard canton |

| Kev nqus dej | Tsawg dua 1% |

| nplaim-retardant theem | Qib B |

| Lub sij hawm them nyiaj | 30% T / T ua ntej, tshuav 70% them ua ntej xa khoom |

| Lub sijhawm xa khoom | Hauv 30 hnub |

| Lus ceeb toom | Cov xim thiab qhov loj tuaj yeem hloov tau raws li koj qhov kev thov |

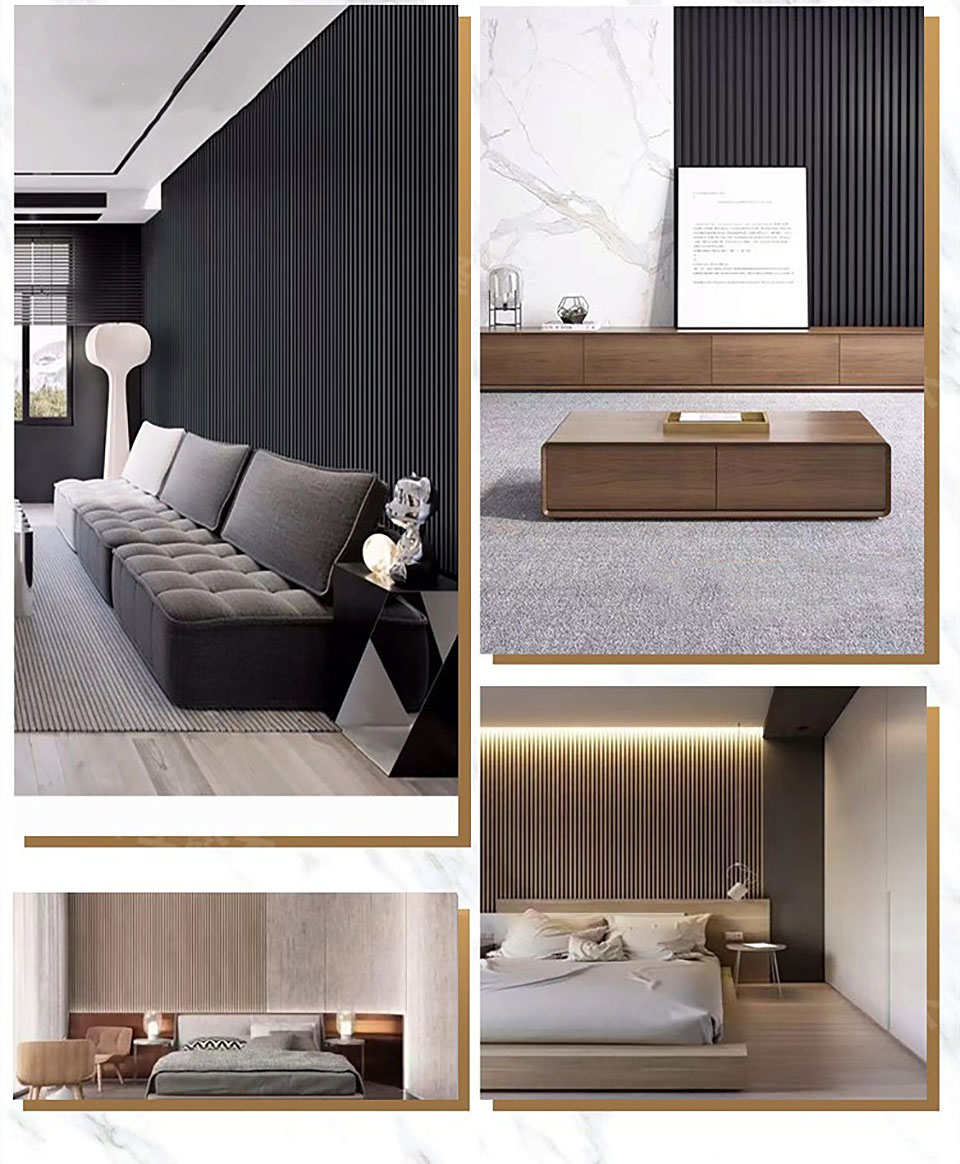

| Daim ntawv thov

Qhov zoo

| Tsev so, tsev lag luam, tsev kho mob, tsev kawm ntawv, chav ua noj hauv tsev, chav dej, kho kom zoo nkauj sab hauv thiab lwm yam |

| 1) Dimensional stability, ntev lub neej, ntuj xav | |

| 2) Resistance rau rot thiab tawg | |

| 3) ruaj khov tshaj qhov kub ntau, huab cua-resistant | |

| 4) Moisture resistant, tsis tshua muaj nplaim taws | |

| 5) High cuam tshuam resistant | |

| 6) Cov ntsia hlau zoo thiab ntsia hlau tuav | |

| 7) Ib puag ncig tus phooj ywg, recyclable | |

| 8) Ntau yam ntawm tiav thiab tsos | |

| 9) Yooj yim tsim thiab yooj yim fabricated | |

| 10) Tsis muaj tshuaj lom lossis tshuaj tua kab mob |

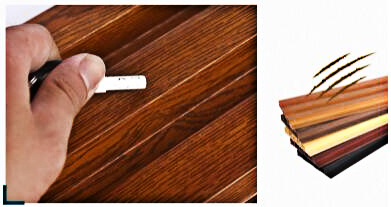

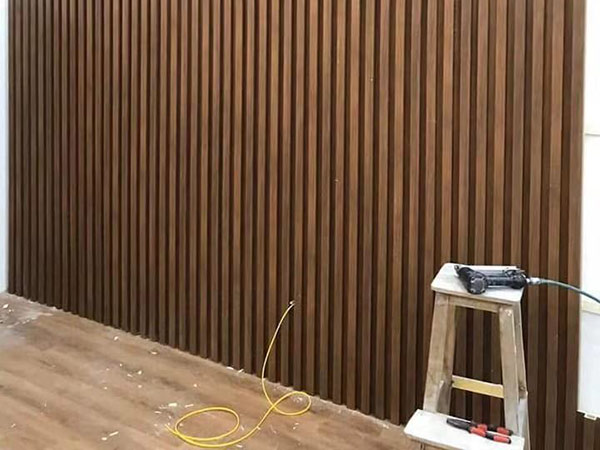

Sab hauv Phab Ntsa Vaj Huam Sib Luag Teeb Duab

Qhov zoo ntawm phab ntsa vaj huam sib luag

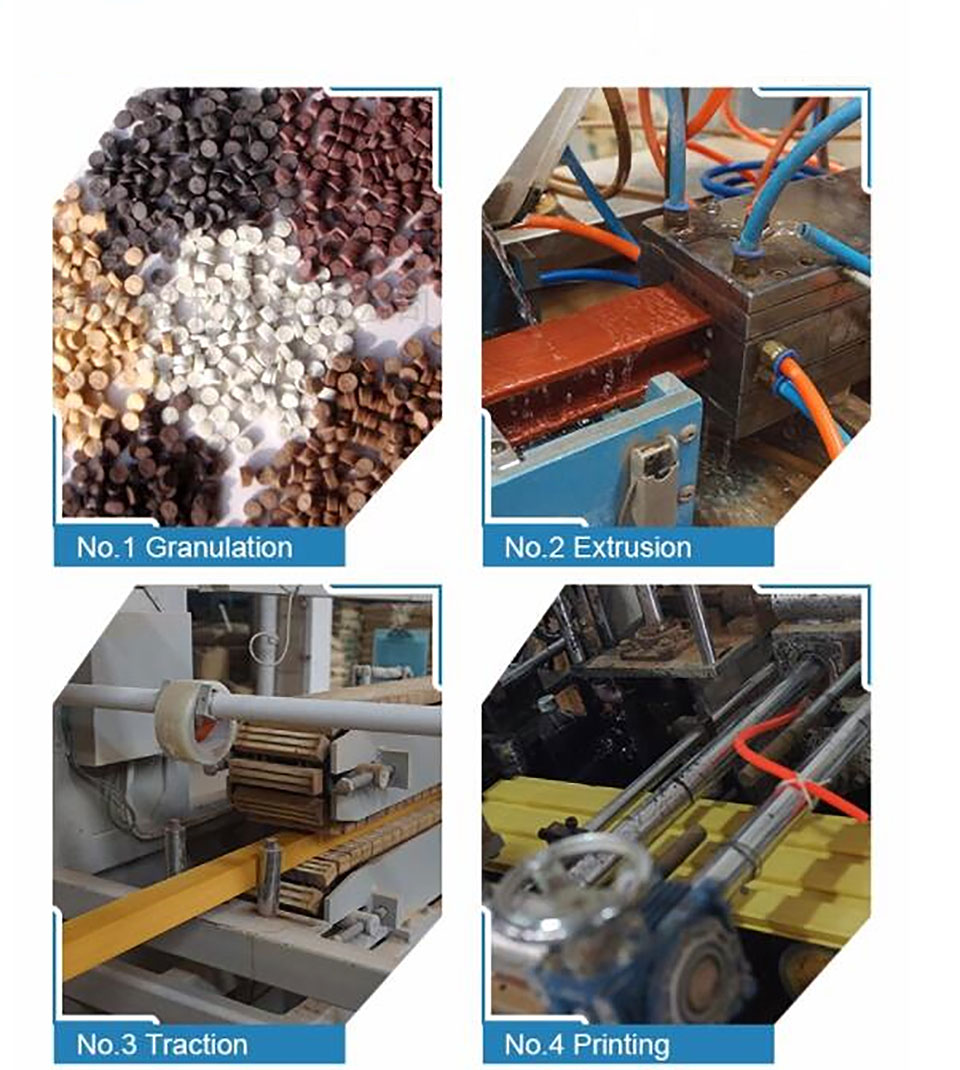

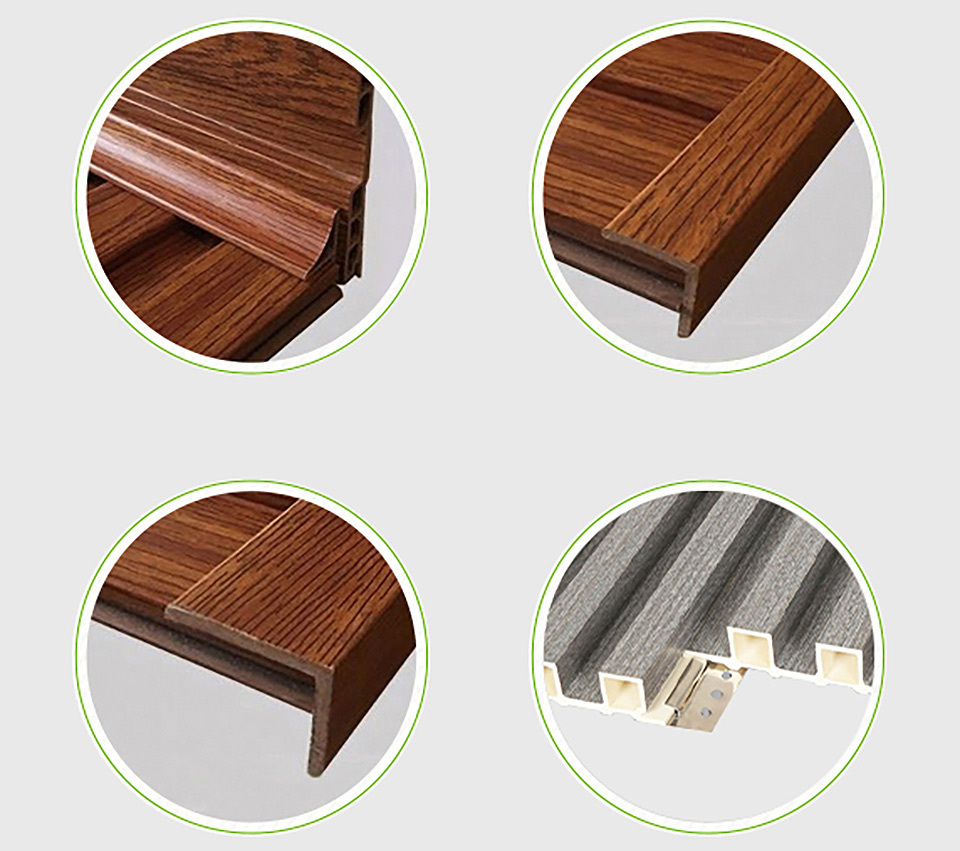

Wpc Phab Ntsa Vaj Huam Sib Luag Txheej Txheem

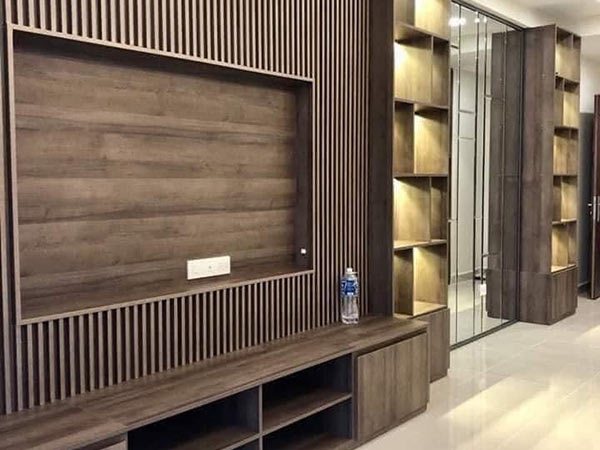

Daim ntawv thov

Qhov project 1

Qhov project 2

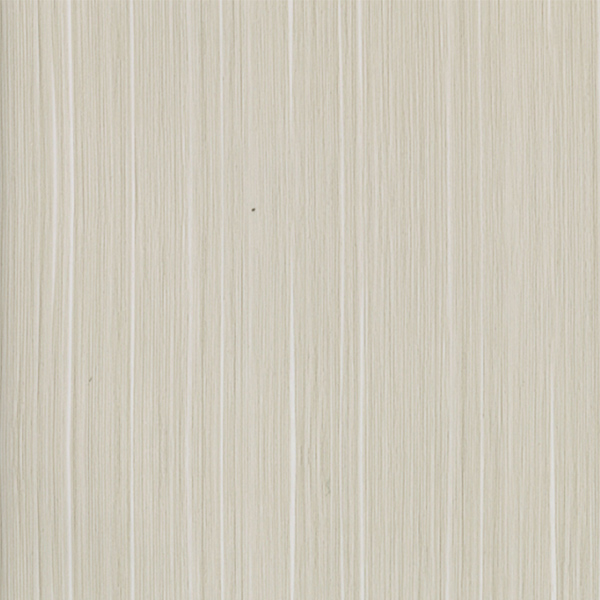

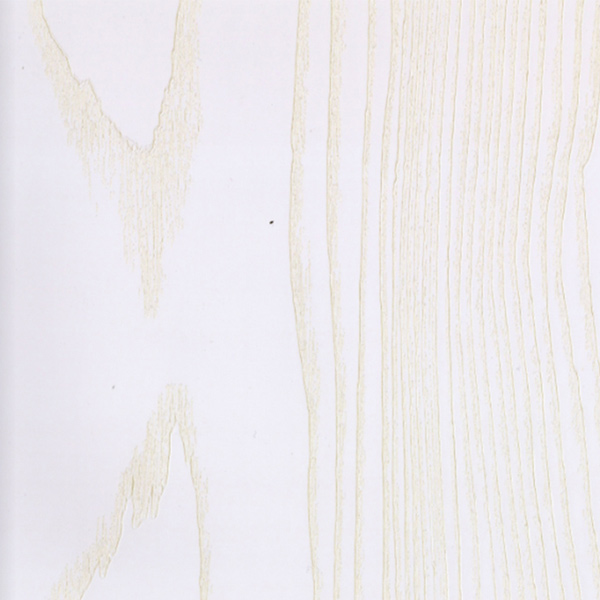

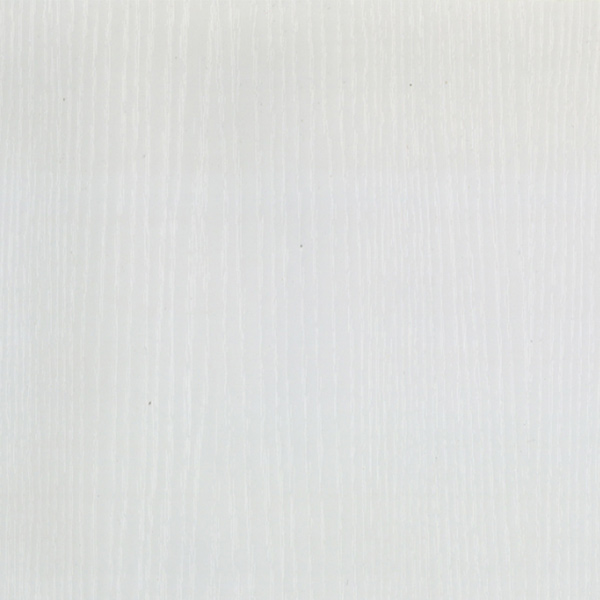

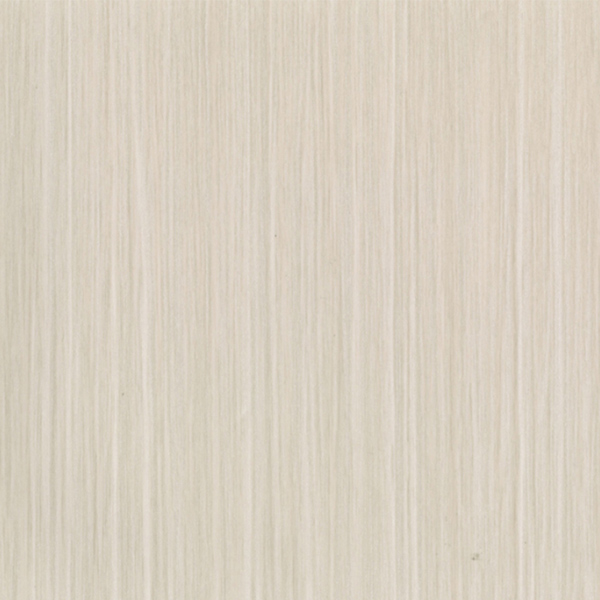

Cov Xim Xim

Cov Xim Xim

Kev teeb tsa

Kev teeb tsa

1.Interior Wpc cladding Vaj Huam Sib Luag Installation Video tutorial 1:

Siv lub tshuab ntsia hlau ntsia hlau ncaj qha los kho tus ntsia hlau ntawm ntug ntawm phab ntsa vaj huam sib luag xauv los txhim kho phab ntsa

2.Interior Wpc Louvre Installation Video tutorial 2:

Thaum cov phab ntsa tsis sib xws, siv styrofoam rau sab nraum qab ntawm Wpc Louvre board, thiab ncaj qha siv cov ntsia hlau ntsia hlau los kho cov ntsia hlau ntawm ntug ntawm phab ntsa vaj huam sib luag txhawm rau txhim kho phab ntsa.

3.Indoor Wpc Phab Ntsa Cladding Install Video tutorial 3:

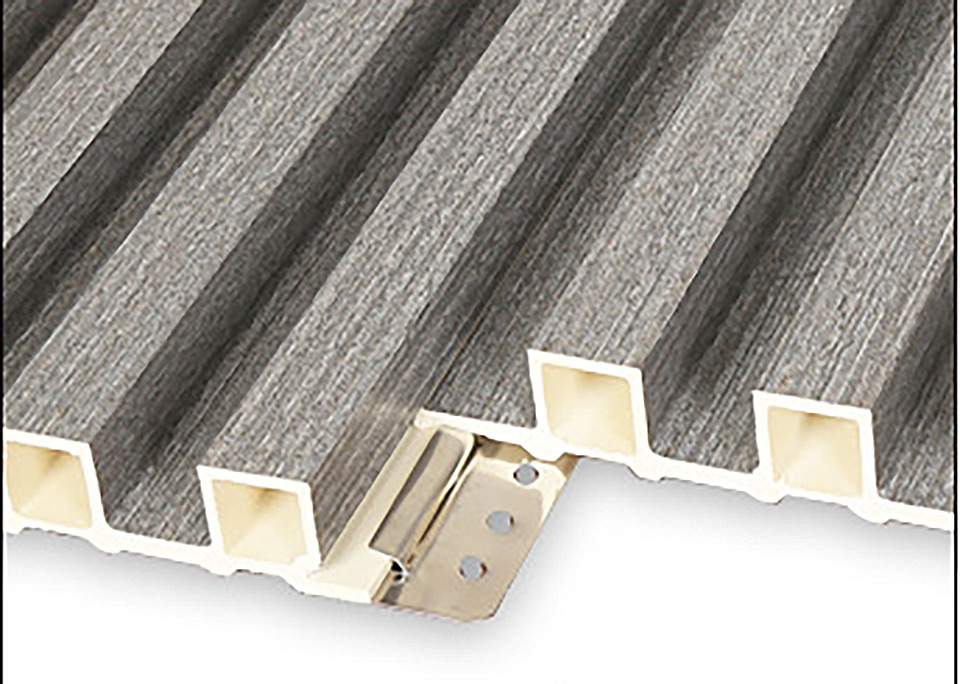

Txhim kho phab ntsa Cladding xauv ncaj qha los ntawm cov hlau clips, yog tias qhov flatness ntawm phab ntsa ua tau raws li qhov yuav tsum tau ua

Accessories rau Wpc Phab ntsa

Accessories rau Wpc Phab ntsa

1.Concave kab

2.L ntug

3. Hlau Clips

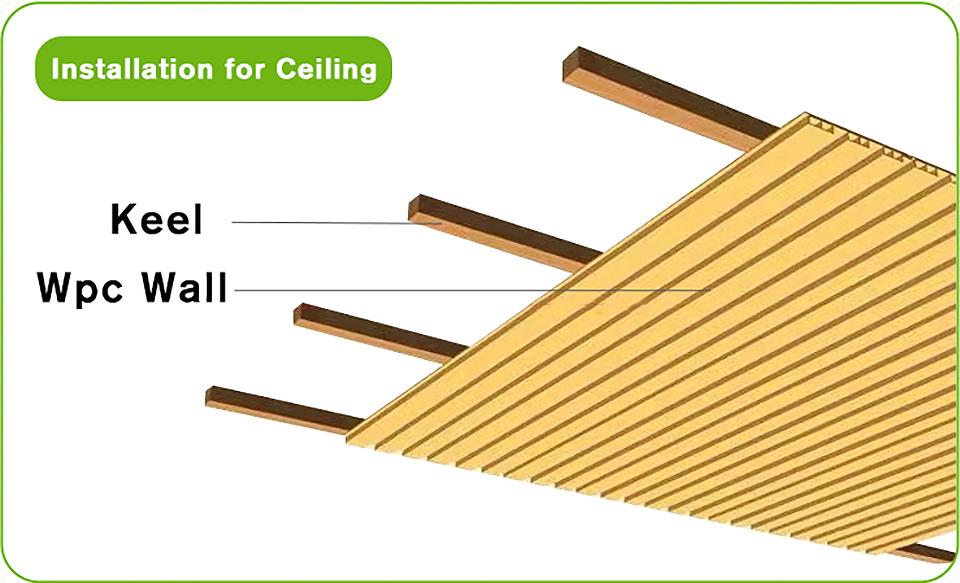

Wpc Phab Ntsa Installation rau phab ntsa thiab qab nthab

Wpc Phab Ntsa Installation rau phab ntsa thiab qab nthab

Thawj kauj ruam yog kom paub meej tias cov phab ntsa puas tiaj tus.Yog tias phab ntsa tiaj tus, koj tuaj yeem nruab sab hauv tsev wpc phab ntsa ncaj qha rau ntawm phab ntsa.Yog tias phab ntsa tsis sib npaug, koj yuav tsum tau nruab cov ntoo keels ntawm phab ntsa ua ib qho kev txhawb nqa ua ntej, thiab qhov kev ncua deb ntawm txhua keel yuav tsum yog 25 cm sib nrug.

Hauv cov kauj ruam thib ob, txij li lub vaj huam sib luag sab hauv tsev wpc yog nias lub xauv, nws tsuas yog tsim nyog los txhim kho lub vaj huam sib luag rau phab ntsa los yog keel los ntawm cov hlau clips.

Qhov thib peb kauj ruam, thaum thawj phab ntsa vaj huam sib luag yog tsau nyob rau hauv lub thib ob kauj ruam, tom qab lub thib ob phab ntsa yog muab tso rau hauv thawj phab ntsa vaj huam sib luag xauv, rov ua lub thib ob kauj ruam los txhim kho phab ntsa vaj huam sib luag ntawm phab ntsa los yog keel.

Kauj ruam plaub, rov ua kauj ruam thib peb

| No | Yam ntxwv | Lub Hom Phiaj Technology | Lus ceeb toom | |||||

| 1 | Qhov tshwm sim | Tsis muaj chipping, cracking, pom kev ntxhib los mos, delamination, npuas, ntiav embossing, khawb, av, tsis zoo txiav, thiab lwm yam | TIAB SA 649 | |||||

| 2 | Loj mm (23 ℃) | Ntev | ± 0.20 hli | TS EN 427 | ||||

| Dav | ± 0.10 hli | TS EN 427 | ||||||

| Thickness | 0.13 hli, -0.10mm | TS EN 428 | ||||||

| Thickness Ntau | ≤0.15 hli | TS EN 428 | ||||||

| Hnav Thickness | ± 0.02 hli | TS EN 429 | ||||||

| 3 | Squareness mm | ≤ 0.15 | TS EN 427 | |||||

| 4 | Khob mm | ≤ 0.15 | TS EN 427 | |||||

| 5 | Microbevel txiav lub kaum sab xis | 8-15 degrees | ||||||

| Microbevel Txiav Qhov tob | 0.60-1.5 hli | |||||||

| 6 | Dimension stability tom qab raug tshav kub | ≤ 0.12% | TS EN 434 | |||||

| 7 | Curling tom qab raug tshav kub | WPC: ≤0.2 (70 ℃ / 6 teev) | TS EN 434 | |||||

| SPC: ≤0.2 (80 ℃ / 6 teev) | ||||||||

| 8 | Gloss theem | Tus nqi nominal ± 1.5 | Lub teeb ntsuas | |||||

| 9 | Taber Abrasion - Yam tsawg kawg nkaus | 0.5mm hnav lay | ≥5000 cycles Nruab Nrab | TS EN 660 | ||||

| 10 | Uv | 8 ~ 12g / m2 | ||||||

| 11 | ≥ 9 N | |||||||

| SCRATCH PERFORMANCE UV | SCLEROMETER | |||||||

| 12 | Anti-stain kev ua haujlwm | Iodine | 3 | Hloov kho ASTM 92 | ||||

| Roj Hmab | 0 | |||||||

| Mustard | 0 | |||||||

| Muag Polish | 2 | |||||||

| Blue Sharpie | 1 | |||||||

| 13 | Kev txiav txim siab yooj | tsis tawg | TS EN 435 | |||||

| 14 | Peel Resistance | Ntev | ≥62.5N / 5cm | EN431 (62.5N / 5cm, 100 hli / s) | ||||

| dav | ≥62.5N / 5cm | |||||||

| 15 | Residual indentation (nruab nrab) mm | ≤ 0.15 | TS EN 433 | |||||

| 16 | Xim ceev: | ≥7 | ISO 105-B2: 2002 | |||||

| 17 | Xauv Lub Zog | fsmax ≥2.5N / hli | ISO 24344 | |||||

-

Sab hauv thiab sab nrauv Wpc Pvc Qab nthab cuav

-

Nthuav SPC Phab Ntsa Panels Ntaub tsim

-

Yas Wpc Ntoo Tube rau Chaw Ua Haujlwm thiab Tsev So Phab Ntsa

-

100% Waterproof Wainscoting Vaj Huam Sib Luag 204.15mm

-

Txiv kab ntxwv, dawb, rov qab, xiav thiab ntsuab SPC phab ntsa ...

-

Chav Dej Phab Ntsa Cladding 199.13mm