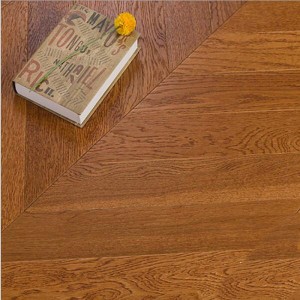

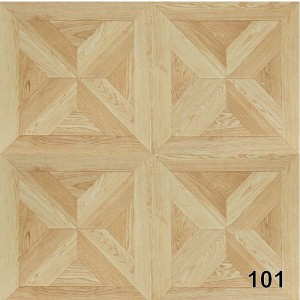

Tsarin

Cikakkun Hotuna

Ƙayyadaddun bayanai

| Farashin SPCƘayyadaddun Falo | |

| Kauri | 3.8mm, 4mm, 4.2mm, 5mm, 5.5mm, 6mm |

| Saka Layer | 0.2mm, 0.3mm, 0.5mm |

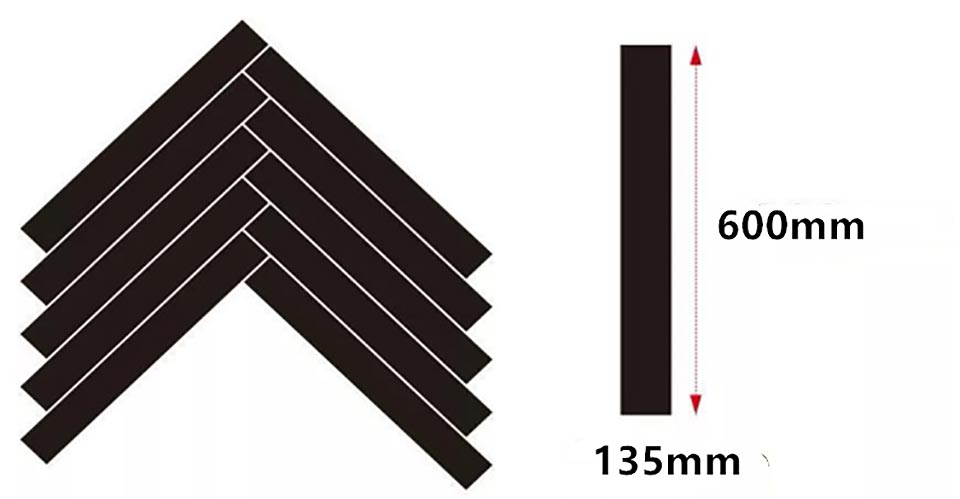

| Girman | 600*135mm |

| Surface | Crystal, Haske/Tsarin Ƙaƙwalwa, Itace ta Gaskiya, Hannu |

| Core Material | 100% budurwa kayan |

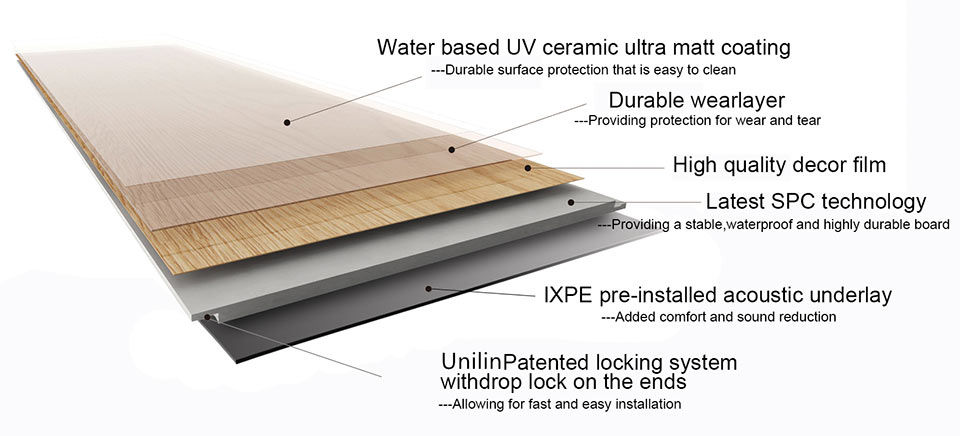

| Danna Tsarin | Unilin Danna, Kulle Kulle (I4F) |

| Magani na musamman | V-Groove, Mai hana Sauti EVA/IXPE |

| Hanyar shigarwa | Yawo |

Girman

Taimakon bene na SPC

Tallafin IXPE

Taimakon EVA a bayyane

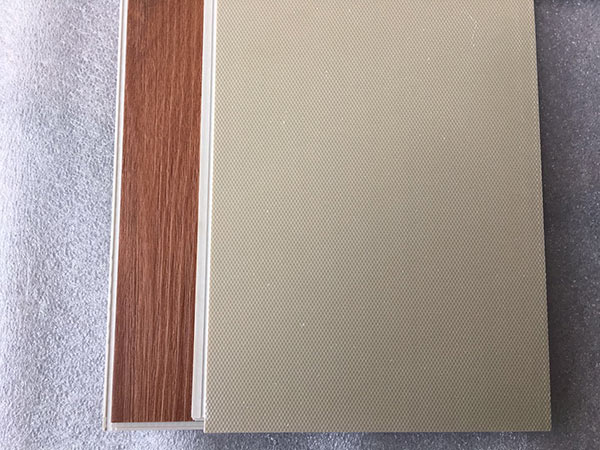

Nau'in Ƙarshe

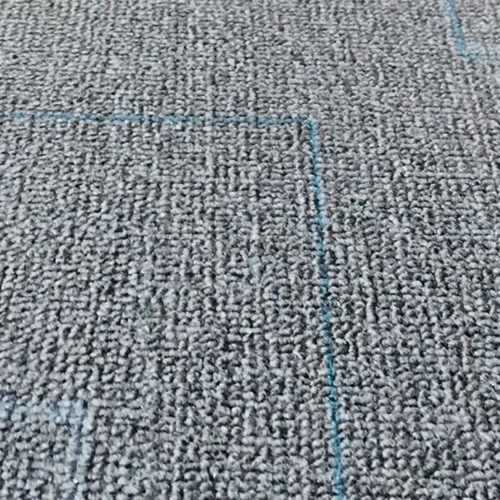

Kafet Surface

Crystal Surface

Zurfafa Embossed Surface

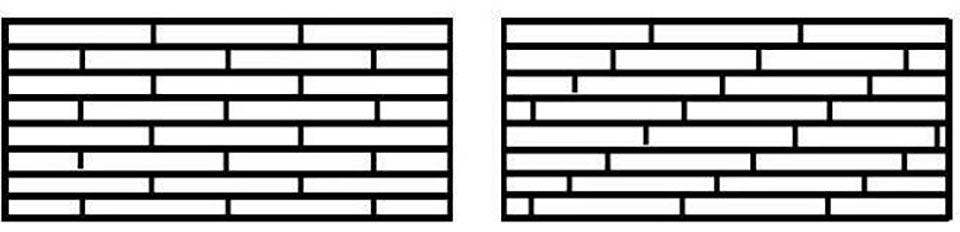

Wuraren shimfidar Hannun Spc

Surface Fata

Haske Embossed

Marmara Surface

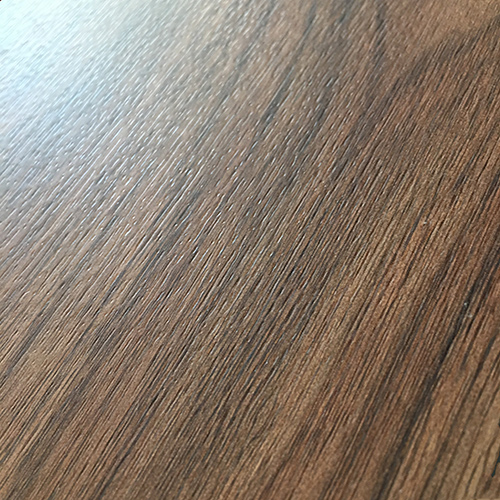

Itace Gaskiya

Menene Bambanci Tsakanin 100% Budurwa Spc Flooring da Sake Fa'idar Spc Flooring?

Gwajin Ingantacciyar Ruwa Mai Tsabtace Dani Spc

Haɗin gwiwa na shimfidar shimfidar Spc

Unilin Danna 1

Unilin Danna 2

Jerin Shiryawan bene na SPC

| Herringbone SPC Floor | |||||||||

| Girman | sqm/pc | kgs/sqm | pcs/ctn | sqm/ctn | ctn/pallet | pallet/20ft | sqm/20ft | ctns/20ft | Nauyin Kaya/20ft |

| 600*135*4mm | 0.0810 | 8.2 | 26 | 2.10600 | 72ctn/10 pallet, 84ctn/10 pallet | 20 | 3285.36 | 1560 | 27400 |

| 600*135*5mm | 0.0810 | 10.2 | 20 | 1.62000 | 72ctn/10 pallet, 84ctn/10 pallet | 20 | 2527.20 | 1560 | 25777 |

| 600*135*6mm | 0.0810 | 12.2 | 18 | 1.45800 | 72ctn/10 pallet, 84ctn/10 pallet | 20 | 2275.00 | 1560 | 27750 |

Amfani

Gwajin Gwajin Ƙaƙwalwar Ƙasa ta SPC

Gwajin hana Wuta na bene na SPC

Gwajin hana ruwa na bene na SPC

Aikace-aikace

Blackbutt Spc Project a Ostiraliya - 1

Spotted Gum Spc Flooring Project a Ostiraliya - 2

Tsarin Kariyar bene na SPC

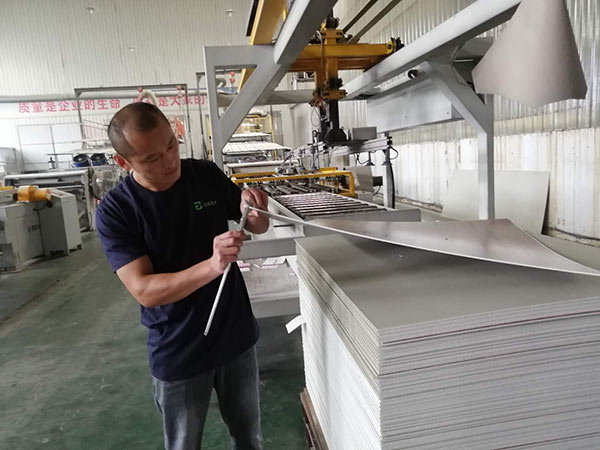

1 Taron bita

4 Hukumar Lafiya ta SPC

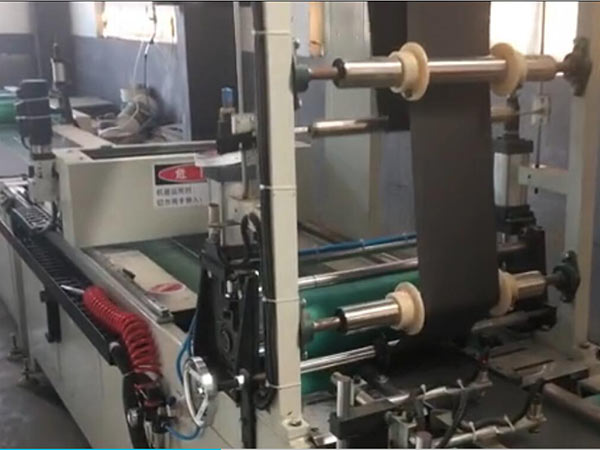

7 SPC Danna Macking Machine

10 Gidan ajiya

2 SPC Coextrusion Machine

5 Gwajin ingancin SPC

8 Injin Ƙara Kumfa

11 Lodawa

3 UV Machine

6 SPC Yankan Machine / karfi>

9 Laboratory

A. Drop Click Spc Flooring Installation

A. Drop Click Spc Flooring Installation

B. Unilin Click Spc Flooring Installation

B. Unilin Click Spc Flooring Installation

HANYAR SHIGA BANA SPC

HANYAR SHIGA BANA SPC

1. Da farko, ƙayyade yadda kuke son bene ya gudana.Yawanci don samfuran katako, shimfidar bene yana tafiyar da tsayin ɗakin.Ana iya samun keɓancewa tunda duk batun fifiko ne.

2. Don guje wa kunkuntar faɗin katako ko gajerun tsayin alluna kusa da bango/ƙofofi, yana da mahimmanci a yi wasu tsarawa.Yin amfani da faɗin ɗakin, ƙididdige cikakken allon allon nawa ne za su dace da wurin da sauran sarari waɗanda za su buƙaci a rufe da katako.Raba sauran sarari biyu don ƙididdige faɗin faɗuwar katako.Yi haka tare da tsayi.

3. Lura cewa jere na farko na katako baya buƙatar gyarawa a cikin nisa, zai zama dole a yanke harshen da ba a goyan baya ba don haka mai tsabta, m gefen bango yana zuwa bango.

4. Ya kamata a kiyaye ramukan fadada 8mm daga bango yayin shigarwa.Wannan zai ba da damar sararin samaniya gibin faɗaɗa dabi'a da raguwar katako.

5. Ya kamata a shigar da katako daga dama zuwa hagu.Daga saman kusurwar dama na dakin, sanya katako na farko a wuri don duka biyun kai da gefen kabu sun fito fili.

6. Shigar da katako na biyu a jere na farko ta hanyar karkatar da ɗan gajeren harshe na gefen cikin dogon gefen katako na farko.

7. Don fara jere na biyu, yanke katako wanda ya fi guntu aƙalla 152.4mm fiye da katako na farko ta hanyar saka dogon harshe na gefe a cikin ramin katako a jere na farko.

8. Shigar da katako na biyu a jere na biyu ta hanyar saka ɗan gajeren harshe na gefe a cikin tsagi mai tsayi na gefe na farko da aka shigar a baya.

9. Daidaita katako ta yadda gajeriyar titin harshen gefen ta kasance a kan madaidaicin leben katako a jere na farko.

10. Yin amfani da ƙarfi mai laushi kuma a kusurwar digiri 20-30, tura ɗan gajeren harshe na gefe zuwa cikin tsagi na katako mai kusa ta hanyar zamewa tare da dogon gefen gefe.Kuna iya buƙatar ɗaga katakon zuwa damansa kaɗan don ba da damar yin aikin "zamiya".

11. Za a iya shigar da sauran katako a cikin dakin ta amfani da wannan fasaha.Tabbatar cewa ana kiyaye gibin faɗaɗa da ake buƙata akan duk kafaffen sassa na tsaye (kamar bango, kofofi, kabad da sauransu).

12. Za a iya yanke katako cikin sauƙi da wuka mai amfani, kawai a zura saman katakon sannan a datse katakon gida biyu.

Spc shimfidar shigarwa zane

Spc shimfidar shigarwa zane

| Halaye | Ƙayyadaddun Gwaji da Sakamako |

| Girma (a cikin inci) | 6×36;6×48;7×48;8×48;9×48;12×24;12×48;12×36;18×36 |

| Kauri | 3.8mm, 4.0mm, 4.5mm, 5.0mm, 5.5mm, 6.0mm |

| Abin da aka makala / Taimakawa | 1.5mm ko 2.0mm IXPE da Eva |

| Bakar fata | ASTM F2055 - Wucewa - 0.010 in. max |

| Girma da Haƙuri | ASTM F2055 - Yana wucewa - +0.016 a kowace ƙafar layi |

| Kauri | ASTM F386 - Wucewa - Naƙasasshe +0.005 in. |

| sassauci | ASTM F137 - Wuce - ≤1.0 in., babu tsagewa ko karye |

| Ƙarfafa Girma | ASTM F2199 - Yana wucewa - ≤ 0.024 in. kowace ƙafar madaidaiciya |

| Kasancewar Karfe Mai nauyi / Rashi | TS EN 71-3 C - Haɗu da ƙayyadaddun bayanai(Lead, Antimony, Arsenic, Barium, Cadmium, Chromium, Mercury da Selenium). |

| Resistance Generation Hayaki | TS EN ISO 9239-1 Sakamako Mai Mahimmanci 9.1 |

| Juriya na Ƙarfafa Hayaki, Yanayin Ƙunƙara | EN ISO |

| Flammability | ASTM E648- Matsayi na 1 |

| Ragowar Shiga | ASTM F1914 - Yana wucewa - Matsakaicin ƙasa da 8% |

| Iyakar Load A tsaye | ASTM-F-970 Ya wuce 1000psi |

| Abubuwan Bukatun Wear Group pr | TS EN 660-1 Rashin Kauri 0.30 |

| Juriya Zamewa | ASTM D2047 - Wuce -> 0.6 Rigar, 0.6 bushe |

| Juriya ga Haske | ASTM F1515 - Wucewa - ∧E ≤ 8 |

| Juriya ga Zafi | ASTM F1514 - Wuce - ∧E ≤ 8 |

| Halin Lantarki (ESD) | TS EN 1815: 1997 2.0 kV lokacin da aka gwada a 23 C + 1 C |

| Ƙarƙashin Ƙarƙashin Ƙasa | Dace don sakawa a ƙarƙashin dumama ƙasa. |

| Curling Bayan Fuskantar zafi | EN 434 <2mm wucewa |

| Abun ciki na Vinyl da aka sake fa'ida | Kusan 40% |

| Maimaituwa | Ana iya sake yin fa'ida |

| Garanti na samfur | Shekaru 10 na Kasuwanci & Matsayin Shekaru 15 |

| Floorscore Certified | Takaddar Takaddar Da Aka Bata Bayan Buƙata |