What is WPC Deck Tiles?

The main materials of WPC Deck Tiles are PE and wood flour or bamboo flour. After adding additives and mixing at high speed, the pellets are made, and then the pellets are extruded into the molding material by an extruder, and then it is made into a square shape. Coupled with plastic locks, this type of floor can be used for outdoor platforms and indoor balconies such as gardens, villas, etc.

WPC Deck Tile Vs Anticorrosive wood decking

The gap between wood-plastic flooring and anti-corrosion wood is obvious. Anti-corrosion wood is more harmful to people and requires maintenance, which leads to extremely high hidden costs.

Wood-plastic flooring is a new home material, but because of its environmental protection and high performance, latecomers are on the top and occupy a large flooring market.

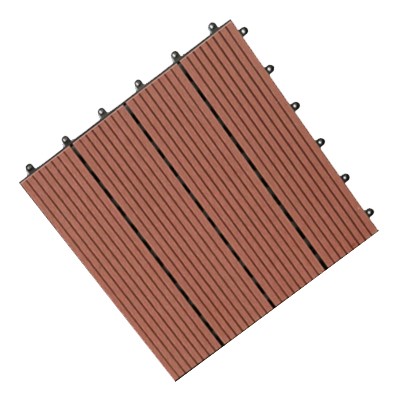

1. WPC DECKING TILES is rich in colors, which can be customized according to customers' preferences, and can also meet the design of different customers for their own private houses.

2. The maintenance cost is low. Due to the extrusion process, the durability and applicability to different environments are particularly strong. It can be said that it is a one-time investment without any additional manual maintenance.

3. High cost performance, not only has the feeling of wood, but also avoids the shortcomings of wood products, such as cracking, not waterproof, etc.

4. New materials, saving wood, keeping the environment alive, and recyclable,

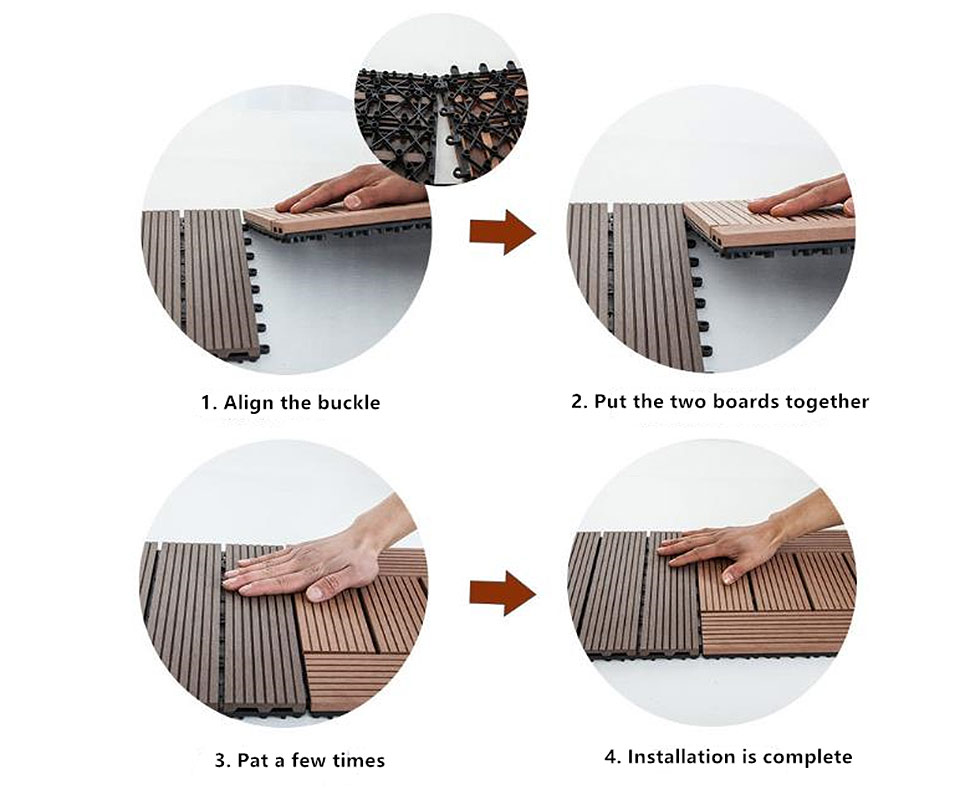

5. Easy installation, providing a complete set of installation instructions and accessories, such as wooden keel, metal bayonet and so on. Can save about 30% installation time.

6. It Can be used indoors and outdoors, Can be used for floor and wall panels, and can be made into various shapes.

In summary, WPC DECKING TILE is the best choice for your home and project

Long Lifespan

Low Maintenance

No Warping or Splintering

Slip-resistant walking surfaces

Scratch Resistant

Stain Resistant

Waterproof

15 Year Warranty

95% recycled wood and plastic

Anti-microbial

Fire Resistant

Easy Installation

Size

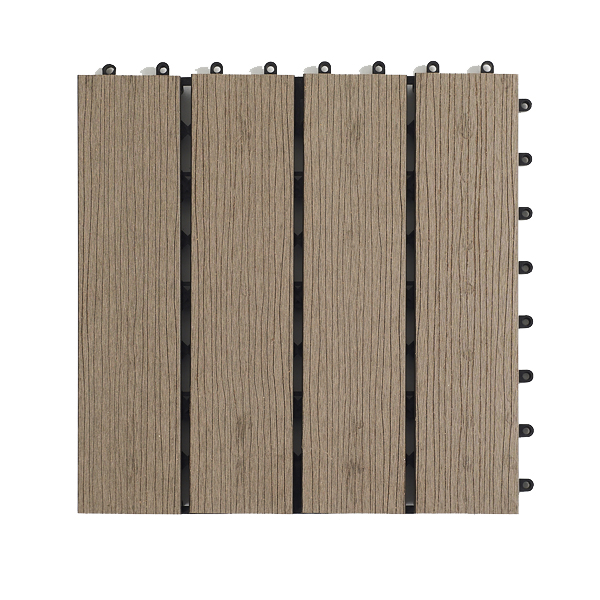

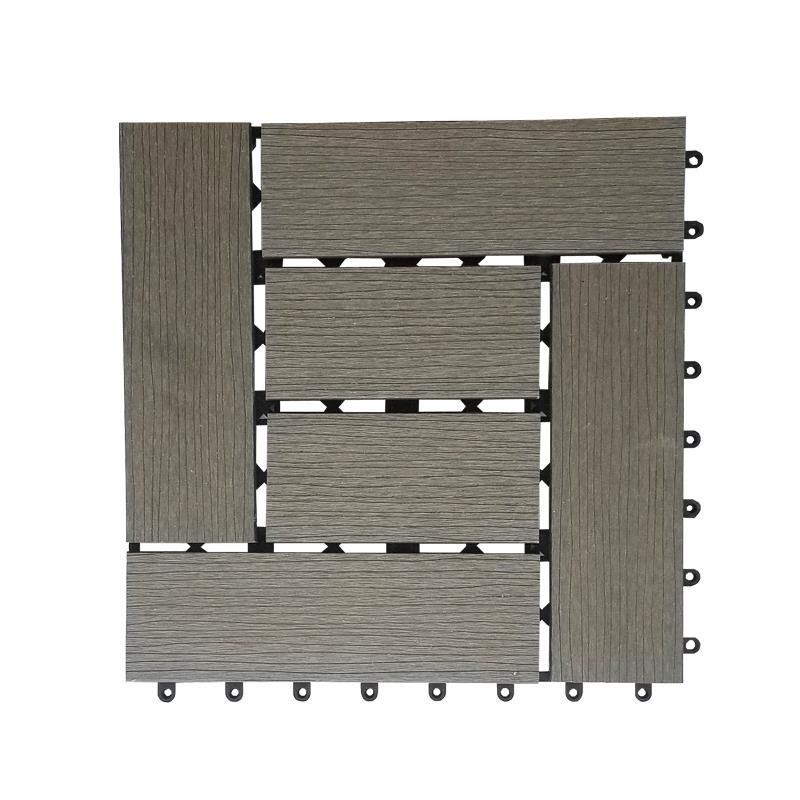

Details Images

DIY Decking Specifications

|

Brand |

DEGE |

|

Series |

DE Deck Tiles |

|

Production process |

Extrusion |

|

Finish |

Brush |

|

Material |

WPC: 32% HDPE, 58% Wood Powder, 10% Chemical Additives |

|

Size |

300*300*22mm |

|

Type |

Hollow, Solid |

|

Usage/Application |

Outdoor |

|

Waterproof |

Yes |

|

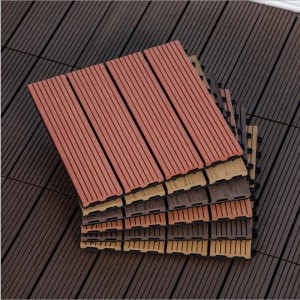

Color |

Red(RW), Maple(MA), Reddish Brown(RB), Teak(TK), Wood(SB), Dark Coffee(DC), Light Coffee(LC), Light Grey(LG), Green(GN) |

|

Surface Treatment |

Grooves, Wood Grain,Bark Grain, Ring Pattern |

|

Applications |

Garden, Lawn, Balcony, Corridor, Garage, Pool Surrounds, Beach Road, Scenic, etc. |

|

Lifespan |

Domestic: 15-20 years, Commercial: 10-15 years |

|

Technical Parameter |

Flexural failure load: 3876N (≥2500N) Water absorption:1.2% (≤10%) Fire-retardant: B1 Grade |

|

Certificate |

CE, SGS, ISO |

|

Packing |

Carton, About 10000PCS/20ft and about 21000PCS/40HQ |

Color Available

WPC Decking Surfaces

Product Process

Applications

Project 1

Project 2

Project 3

Installation steps

Installation steps

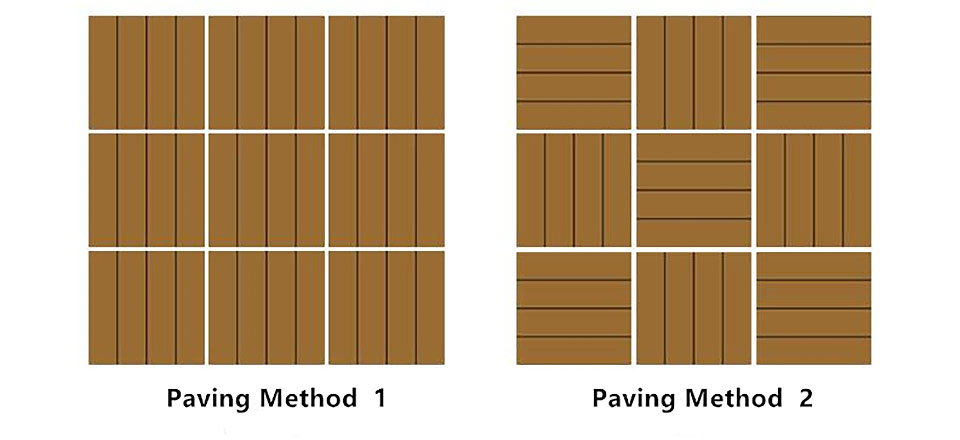

Installation method

Installation method

| Density | 1.35g/m3 (Standard: ASTM D792-13 Method B) |

| Tensile strength | 23.2 MPa (Standard: ASTM D638-14) |

| Flexural strength | 26.5Mp (Standard: ASTM D790-10) |

| Flexural Modulus | 32.5Mp (Standard: ASTM D790-10) |

| Impact strength | 68J/m (Standard: ASTM D4812-11) |

| Shore hardness | D68 (Standard: ASTM D2240-05) |

| Water absorption | 0.65%(Standard: ASTM D570-98) |

| Thermal expansion | 42.12 x10-6 (Standard: ASTM D696 – 08) |

| Slip resistant | R11 (Standard: DIN 51130:2014) |