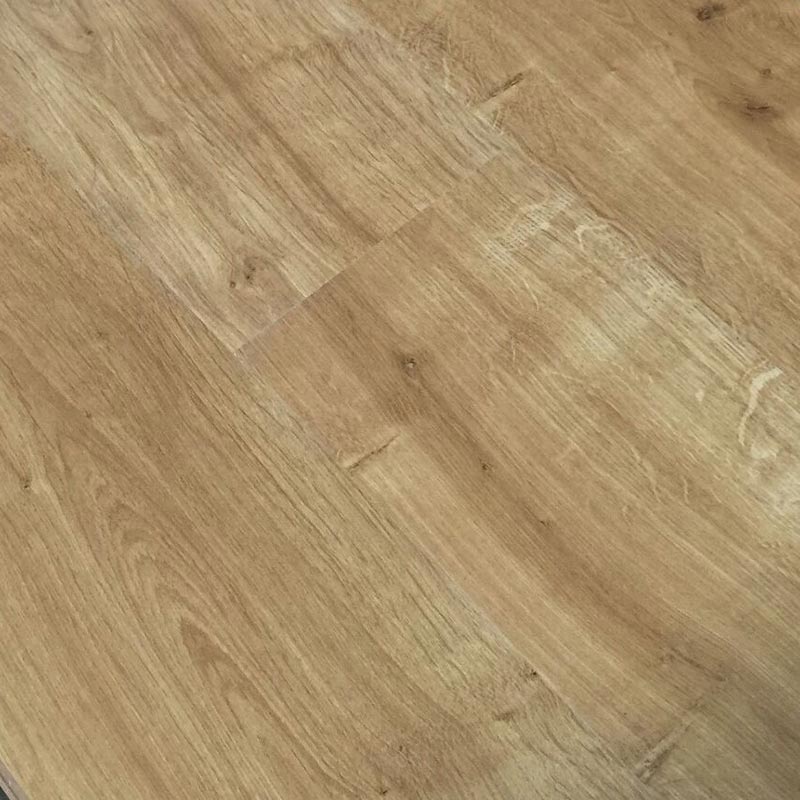

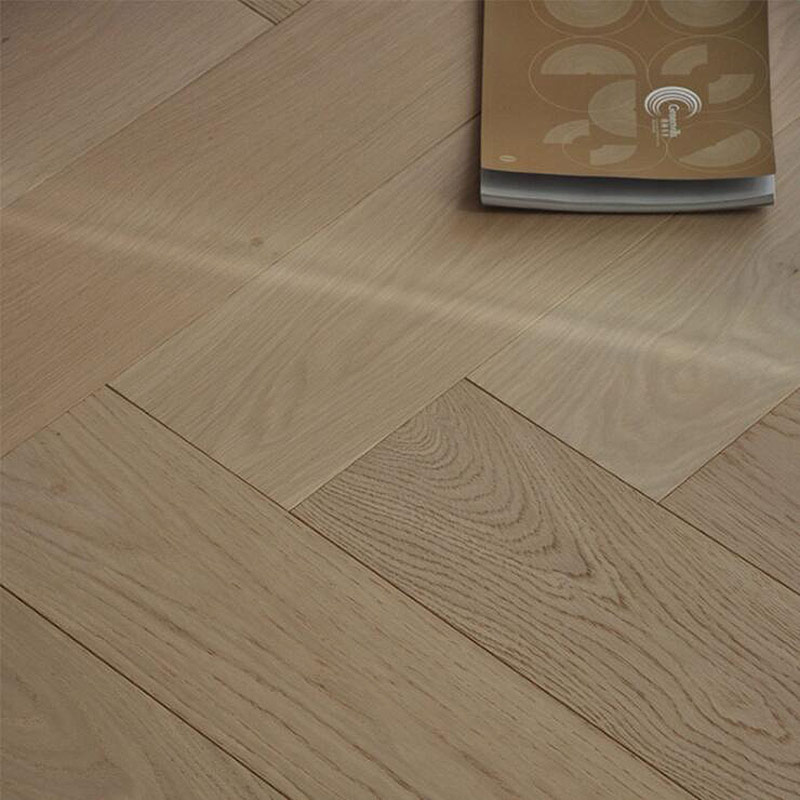

Factory source 8mm Laminate Flooring - 450*60mm Herringbone Wooden Flooring for Australia Market – DEDGE Detail:

3 Layer Engineered Structure

Multilayer Engineered Structure

Engineered Flooring Advantage

Specifications

| Flooring Type | Prefinished | Species | Maple/Hard Maple |

| Color | Brown | Shade | Medium/Neutral Shade |

| Finish Type | Urethane | Gloss Level | Low-Gloss |

| Application | Residential | Core Type | Multi-Ply |

| Profile | Tongue & Groove | Edge Type | French Bleed |

| Maximum Length (in.) | 48 | Minimum Length (in.) | 20 |

| Average length (in.) | 33 | Width (in.) | 5 |

| Thickness (in.) | 0.55 | Radiant Heat Compatible | No |

| Below Grade | Yes | Installation | Floating, Glue Down, Nail Down, Staple Down |

| Certification | CARB II | Wear Layer Thickness (mm) | 3 |

| Surface Finish | Distressed, Handscraped | Finish Warranty (in years) | 25 years |

| Structural Warranty (in years) | 25 Years | Country of Origin | China |

| Packaging Dimensions (inches) | Height: 4.75 Length: 84 Width: 5 | Product Dimensions | Height: 9/16″ Length: 15 3/4 – 47 1/4″ Width: 5″ |

| Sqft / Box | 17.5 | Proposition 65 | Attention California Residents |

What is engineered hardwood floors ?

Engineered hardwood floors is based on poplar, willow or eucalyptus multi-layer boards, and the surface base layer selects natural hardwood oak, walnut, Ash, Teak and other materials as the panel. After coating with resin glue, it passes through high temperature and pressure in a hot press Made.

Floors Production Process:

The First step:

The choice of wood types and grades for the substrate layer, the commonly used substrate layers are pure eucalyptus, poplar eucalyptus, eucalyptus and birch; grades B1 and B2

The second step:

Rotate the log into 1.5mm thick and undamaged sheets, and then dry them

third step:

In order to ensure the quality of the substrate layer, professionals must be selected and classified according to thickness, color, stuttering, damage, etc.

the fourth step:

Glue-coated core board: 8-10 layers of glue-coated thin solid wood core boards are arranged in an orderly crisscross pattern and bonded together to change the original stretching direction of wood fibers.

the fifth step:

Through the hot press, the core board and glue are fully integrated and pasted.

The sixth step:

The base material is sanded with a fixed thickness. The surface and bottom of the floor substrate are sanded with a fixed thickness sander to ensure the flatness and smoothness of the board surface and provide an important guarantee for bark pressing

Step Seven:

Substrate sorting and health preservation: After sanding, after selecting and removing defective products, the qualified products are allowed to stand for 15-20 days to release the energy of the substrate layer and make the quality more stable.

The eighth step:

The solid wood veneer is selected, classified according to the grade, and then the moisture content is adjusted according to the climate.

Step 9:

Paste the solid wood bark and the substrate layer with glue, and then put them into a hot press for pressing.

The tenth step:

Continue to keep healthy for 15-20 days to release energy

The eleventh step:

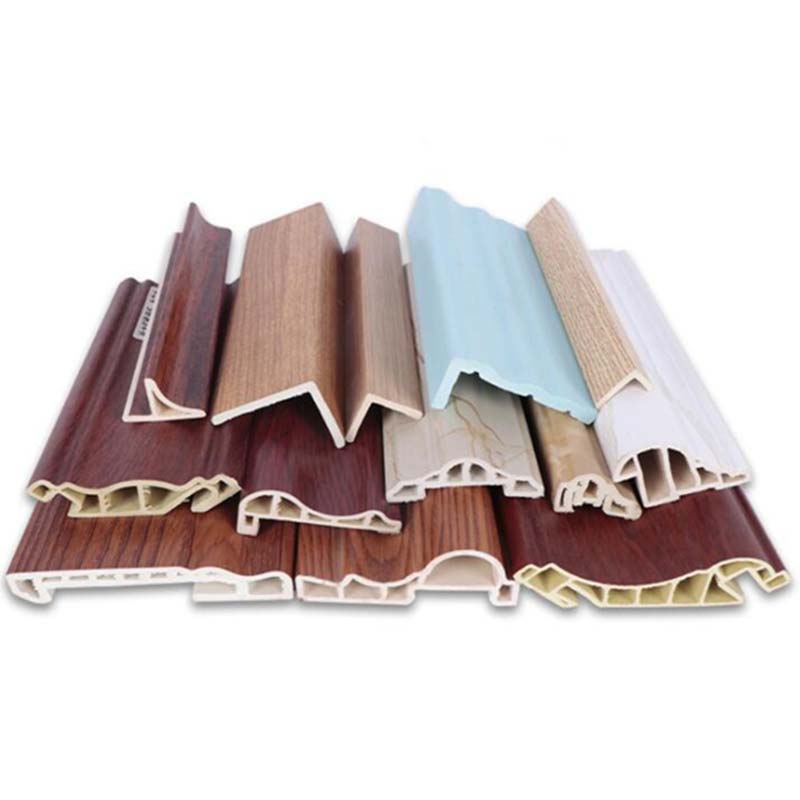

Floor cutting and grooving, all common ones are T&G, Unilin, Valinge, Drop

The twelfth step:

Paint and packaging

After removing the dust, the grooved floor will pass through the paint spraying equipment. After six primers and three top coats, the packaging is sorted.

Design Type

Click Type

Finish Type

Veneer Grade

How to Distinguish Engineered Flooring Veneer Grade

1. Distinguish Method

Grade A: knots are not allowed;

Grade B:Quantity of knots per pc: 1-3pcs and the diameter of knots whose color are black is within 8mm and diameter of knots whose color are nearly same as veneer is within 10mm;

Grade C: Quantity of knots per pc: 1-3pcs and the diameter of knots whose color are black is within 20mm and diameter of knots whose color are nearly same as veneer is within 25mm; In addition, 20% of white edge of plank width is allowed and medium color variation is allowed;

Grade D: Quantity of knots per pc: 1-3pcs and the diameter of knots whose color are black is within 30mm and diameter of knots whose color are nearly same as veneer is unlimited; In addition, length of crack is within 30cm and severe color variation is allowed;

2.Percentage

ABC Grade: Percentage of grade AB: 15%, Percentage of grade C: 85%;

ABCD Grade: Percentage of grade AB: 20%, Percentage of grade C: 50%, Percentage of grade D: 30%

3.Picture

Certificate

Product Process

Our Market

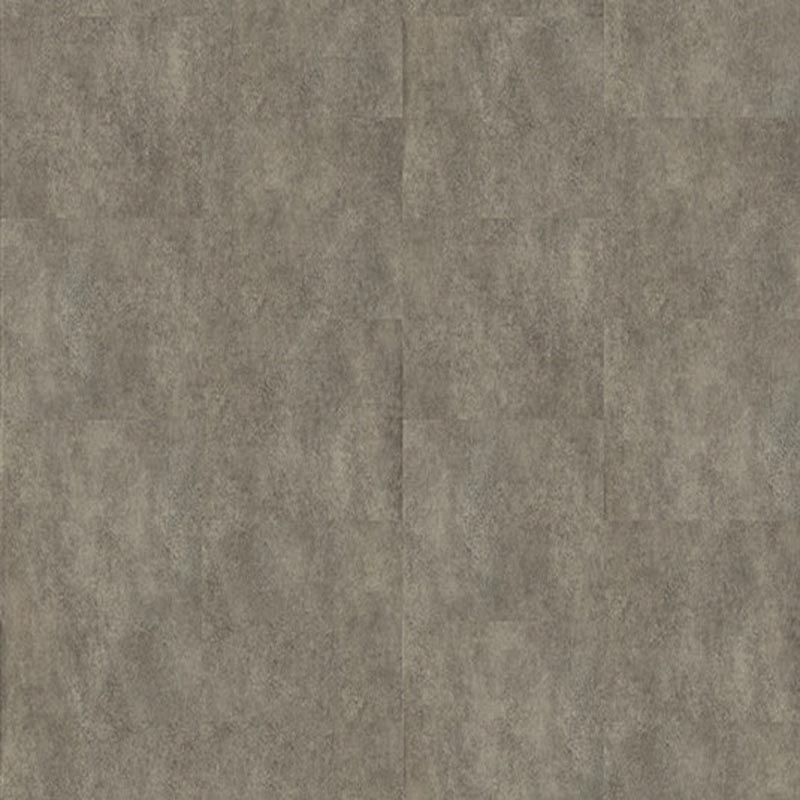

Applications

Project 1

Project 2

Product detail pictures:

Related Product Guide:

"Sincerity, Innovation, Rigorousness, and Efficiency" could be the persistent conception of our enterprise to the long-term to produce together with clients for mutual reciprocity and mutual profit for Factory source 8mm Laminate Flooring - 450*60mm Herringbone Wooden Flooring for Australia Market – DEDGE , The product will supply to all over the world, such as: moldova, Slovenia, panama, It is our customers' satisfaction over our products and services that always inspires us to do better in this business. We build mutually beneficial relationship with our clients by giving them large selection of premium car parts at marked down prices. We provide wholesale prices on all our quality parts so you are guaranteed greater savings.

Reasonable price, good attitude of consultation, finally we achieve a win-win situation,a happy cooperation!