Wood grain textures with more 10 kinds natural-looking colors ,every fence style is designed to similar with wooden fence, but more More durable, reducing subsequent maintenance costs and Easily achieve outdoor life.

DEGE fencing is made with a durable composite that bear bad weather conditions and every day use. The composition of DEGE is 30% of plastic resin, 60% of oak wood fiber and 10% of additive.

Good Water resistant, Environmentally friendly and recyclable materials,you can building your yard without the limitations and up-keep of wood fencing.

What is DEGE Fencing Advantage?

No need sealed, stained or painted

Waterproof ,Anti-termite

Crack resistant,Not deformed

Better adapt to harsh weather, better performance than solid wood

No issues with warping

With no need to maintain or replace

16 years residential warranty

We have good quality outdoor composite fence for sale. If you want make your house more beautiful and want to know the composite privacy fence cost, please contact us. We are glad to serve you.

Details Images

Color Display

Long Lifespan

Low Maintenance

No Warping or Splintering

Slip-resistant walking surfaces

Scratch Resistant

Stain Resistant

Waterproof

15 Year Warranty

95% recycled wood and plastic

Anti-microbial

Fire Resistant

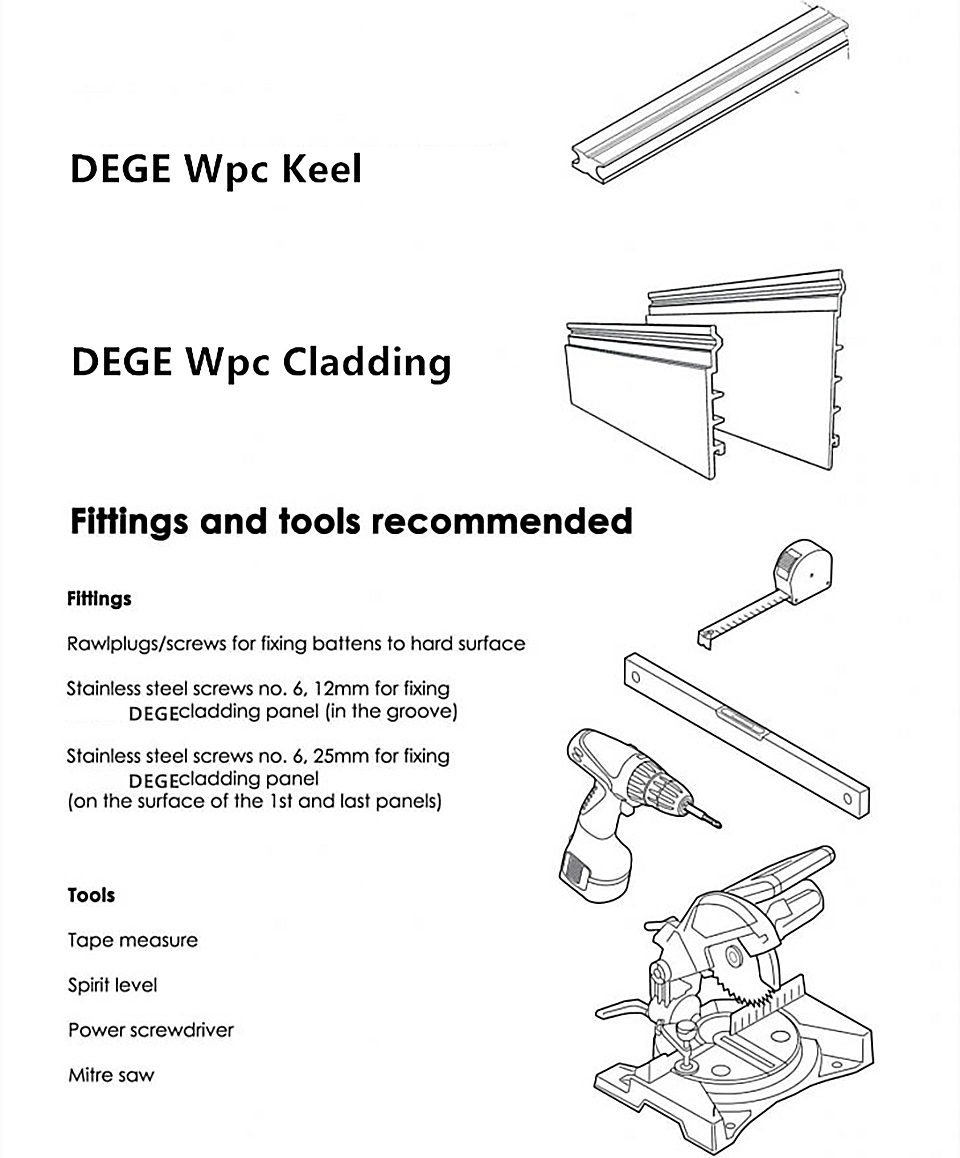

Easy Installation

Parameter

|

Brand |

DEGE |

|

Name |

External UV Wall Cladding |

|

Item |

DE-S117-13A |

|

Standard size |

2900*117*13mm |

|

WPC component |

30% HDPE+60% wood fiber + 10% additives |

|

Accessories |

Patented clip-easy system |

|

Delivery time |

About 20-25 days for one 20'ft container |

|

Payment |

30% deposited, the rest should be paid before deliver |

|

Maintenance |

Free maintenance |

|

Recycling |

100% recyclable |

|

Package |

Pallet or bulk packing |

The Surface Available

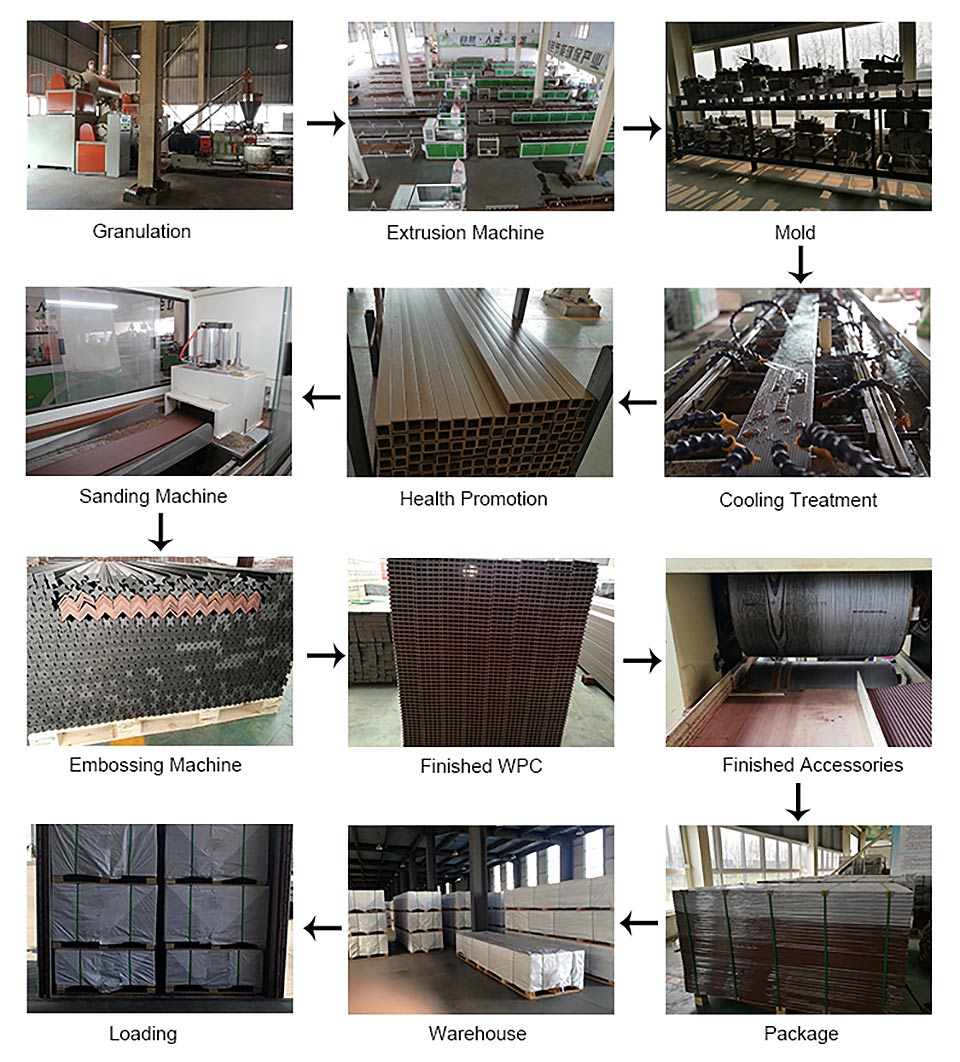

Wpc Wall Panel Production Process

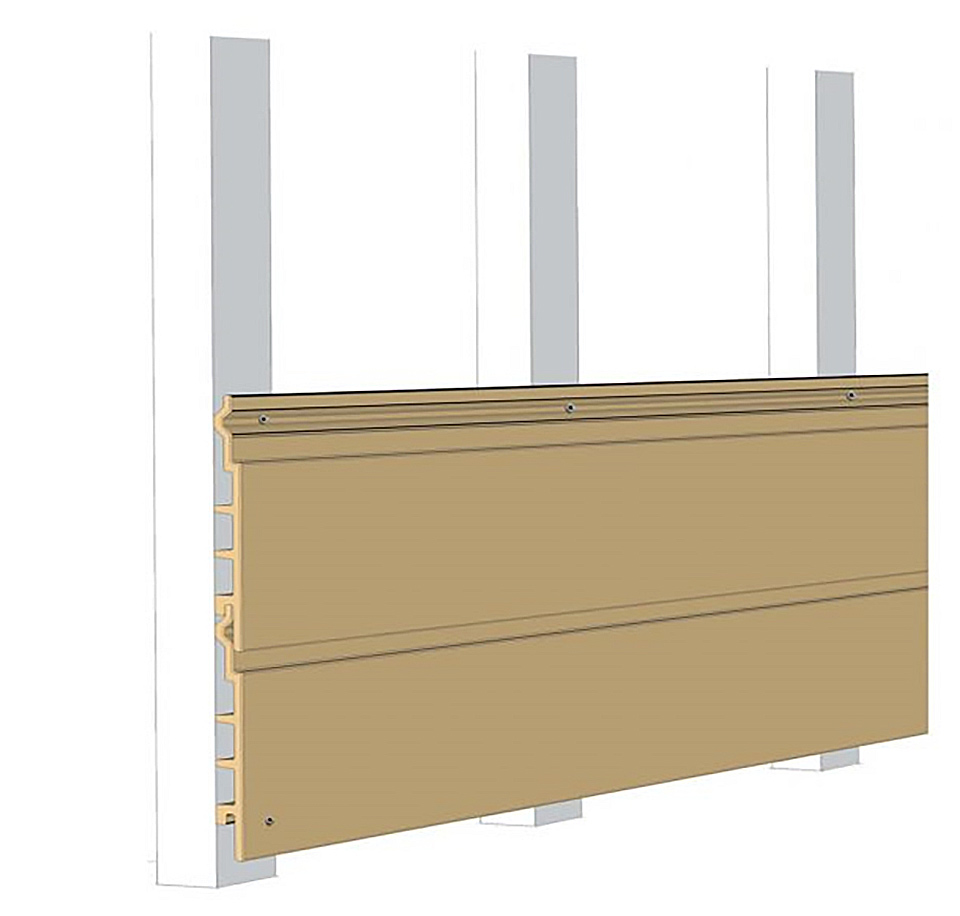

External Wall Cladding Package and Container Loading

Application

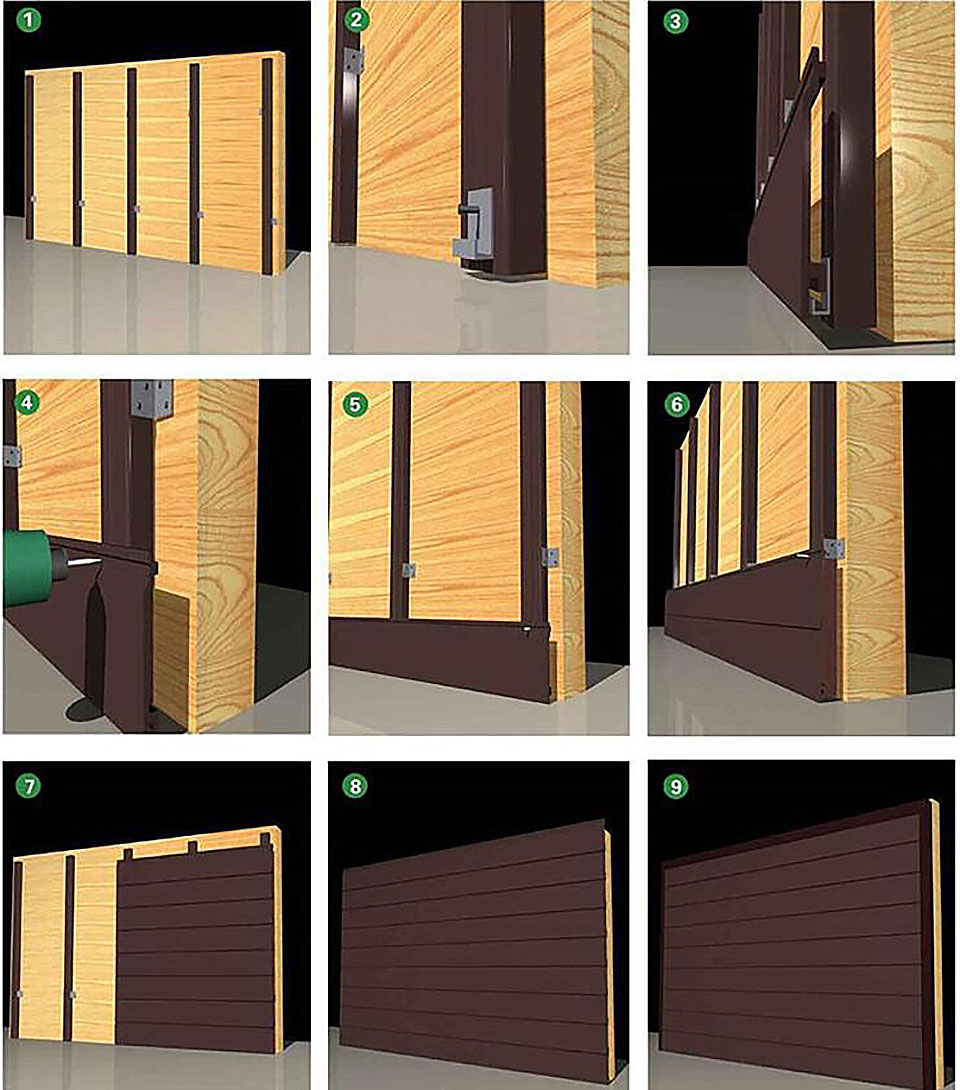

1. Install the keel first

2. Metal buckle installed at the bottom of the keel

3. The bottom wall panel is stuck on the metal buckle

4. Fix the wall panel to the keel with nails

5. The whole wall board needs nails to be fixed on the keel

6. Insert the second wallboard into the first wallboard, and repeat steps 4 and 5

7. The first vertical installation

8. The second vertical installation

9. Add edge banding

| Density |

1.35g/m3 (Standard: ASTM D792-13 Method B) |

| Tensile strength |

23.2 MPa (Standard: ASTM D638-14) |

| Flexural strength |

26.5Mp (Standard: ASTM D790-10) |

| Flexural Modulus |

32.5Mp (Standard: ASTM D790-10) |

| Impact strength |

68J/m (Standard: ASTM D4812-11) |

| Shore hardness |

D68 (Standard: ASTM D2240-05) |

| Water absorption |

0.65%(Standard: ASTM D570-98) |

| Thermal expansion |

42.12 x10-6 (Standard: ASTM D696 – 08) |

| Slip resistant |

R11 (Standard: DIN 51130:2014) |

Project

Project