Carbonized Bamboo Floor

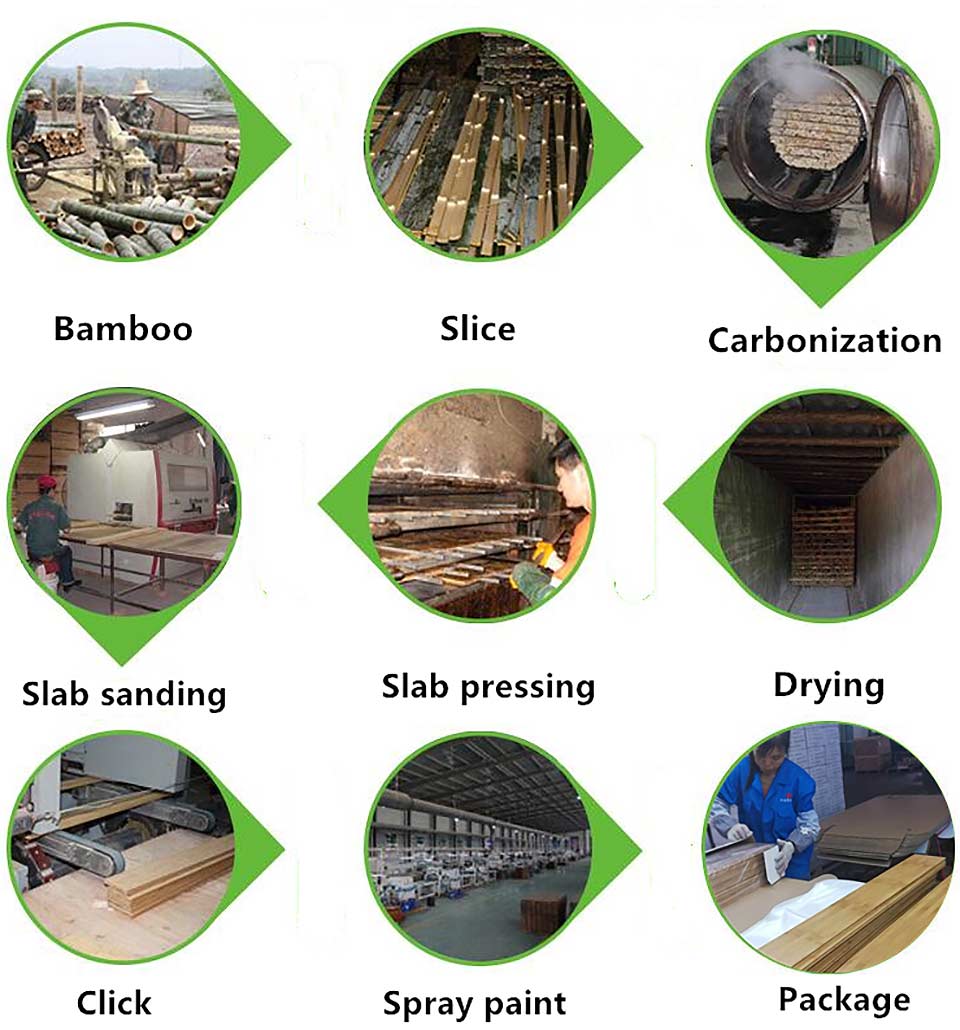

Production Process Bamboo hardwood flooring ?

A.Brief introduction of bamboo flooring production process:

Moso bamboo→cut off→smooth the outer joints→open the strips→remove the inner joints→planing both sides of the bamboo strips (to remove the bamboo green and bamboo yellow)→steaming (anti-insect and anti-mildew treatment) or carbonized coloring treatment→drying→bamboo fine planing →Bamboo strip sorting→Gluing→Assembling blanks→Hot press bonding→Sanding→Fixed length cutting→Four-sided planing (fixed width, back groove)→Double-end milling (horizontal and longitudinal tenoning)→Spray sealing edge paint→ Plain board sanding → sorting → dust removal → water-based primer → hot air drying → putty → UV curing → primer → UV curing → sanding → primer → UV curing → sanding → top coat → UV curing → scratch resistance Finishing paint → UV curing → inspection → packaging

B.Detailed explanation of bamboo flooring production process:

1. Raw bamboo inspection

Bamboo flooring generally uses moso bamboo as the raw material, but the mechanical properties of moso bamboo are closely related to the bamboo age and the location of the material. The bamboo age is less than 4 years, the degree of lignification of the internal components of the bamboo is not enough, the strength is unstable, and the dry shrinkage and swelling rate are large. Bamboos older than 5 years should be used. Bamboo generally has thick roots and thin tips. Therefore, fresh moso bamboos with straight rods with a diameter at breast height greater than 10cm and wall thickness greater than 7mm are generally used as raw materials.

2. Material break

Moso bamboo has thick roots and thin tops. The bamboo tubes are distinguished according to the degree of wall thickness and cut into specified lengths.

3. Punching

Wash the raw bamboo into regular bamboo strips

4 first plan

After drying, the bamboo strips need to be planed on all sides for fine planing on all sides to remove the residual bamboo green, bamboo yellow and knife marks left by rough planing. After this treatment, the bamboo strips and the bamboo strips can be glued firmly without cracks. , No cracking, no delamination. The bamboo strips should be sorted after fine planing, and the bamboo strips that do not meet the requirements of the processing size and have large color differences are removed from the production line.

Preliminary treatment of the surface of the bamboo strips. The surface is shaved and yellowed, that is, the bamboo skin and meat are removed, and only the middle thick fiber layer is retained. Traditional bamboo products are processed by bending the entire cylindrical bamboo material into a prescribed shape. It has not been planed to remove the yellow. The bamboo green on the surface, that is, the density of the bamboo skin part is different from the crude fiber, and the shrinkage deformation rate under the same dry humidity condition Different, so it is easy to cause cracking. The bamboo yellow is the part of the bamboo meat on the inner wall of the bamboo tube. It contains high sugar and other nutrients, and it is easy to grow insects if it is not removed.

In terms of thickness, the flexural strength of bamboo itself is higher than that of wood, and 15mm thick bamboo flooring has sufficient flexural, compressive and impact strength, and has a better foot feel. Some manufacturers, in order to cater to the consumer's mentality that the thicker the better, they do not remove the green or yellow. After the bamboo sheets are glued, although the thickness of the bamboo floor can reach 17mm or 18mm, the bonding strength is not good and it is easy to crack. For high-quality bamboo flooring, the bamboo green and yellow bamboo on both sides of the bamboo are roughly planed. In order to make the bamboo blanks tightly glued, they must be finely planed. The thickness and width tolerances should be controlled within 0.1mm. , The adhesive used for bonding bamboo blanks will also quickly solidify under the action of high temperature, and the adhesion is extremely strong. 5. Cooking bleaching or carbonization

The chemical composition of bamboo is basically the same as that of wood, mainly cellulose, hemicellulose, lignin and extractive substances. However, bamboo contains more protein, sugar, starch, fat, and wax than wood. It is easily eroded by insects and fungi when the temperature and humidity are appropriate. Therefore, bamboo strips need to be cooked after rough planing (natural color). ) Or high-temperature and high-humidity carbonization treatment (brown color) to remove some extracts such as sugar and starch, add insect repellents, preservatives, etc. to prevent the breeding of insects and fungi.

The natural color floor is bleached with hydrogen peroxide at a temperature of 90℃, and the bleaching time is different for different roots with different wall thickness. 3.5 hours for 4~5mm, 4 hours for 6~8mm.

Carbon-colored flooring is processed through a secondary carbonization process under high temperature and high pressure.

The secondary carbonization technology carbonizes all nutrients such as eggs, fat, sugar, and protein in the bamboo, making the material light, and the bamboo fibers are arranged in a "hollow brick" shape, which greatly improves the tensile, compressive strength and waterproof performance.

5. Drying

The moisture content of the bamboo chips after steaming treatment exceeds 80%, reaching a saturated state. The moisture content of bamboo directly affects the stability of the finished product size and shape after bamboo processing. In order to ensure the quality of bamboo flooring products, the bamboo raw materials used for processing must be fully dried before gluing. Bamboo drying is done by drying kiln or track drying kiln.

The moisture content of bamboo materials needs to be controlled according to local climate conditions and use environment. For example, the moisture content controlled in the north and the south of China is different. The moisture content of products used in the north is very low, and should be controlled at 5-9% under normal circumstances.

The moisture content of each unit that makes up the bamboo floor, namely the bamboo strip, is required to be uniform. For example, bamboo string floor (flat plate) requires uniform moisture content of the bamboo strips on the surface, middle and bottom layers, so that it is not easy to deform and bend after the bamboo floor is produced.

This is also an important link to prevent the floor from cracking. Uneven moisture content or excessive moisture content may cause the floor to deform or crack due to changes in environmental factors such as temperature and dry humidity. The moisture content can be set according to the air humidity in different areas. The floor made in this way can guarantee to adapt to the corresponding climate environment.

The high-quality floor undergoes six-point multi-faceted testing during drying to ensure that each piece of bamboo strips, as well as the moisture content of the bamboo strips, the surface and the inside, are balanced, so as to ensure that the floor cracks and deforms due to different humidity environments. It is difficult for consumers to simply measure the moisture content. The safer way to solve this problem is to choose a reputable and regular bamboo flooring manufacturer that can produce slabs.

6.fine planing

Bamboo strips are finely planed to the required specifications.

7.Product selection

Sort the bamboo strips into different levels.

8. Gluing and repressing

Glue and blank assembly: Choose high-quality environmentally friendly adhesives, apply glue according to the prescribed amount of glue and spread evenly, and then assemble the bamboo strips according to the required specifications.

Hot-pressing and gluing: Hot-pressing is a key process. Under the specified pressure, temperature and time, the slab is glued into a blank. The surface finish of the bamboo strips, the adhesive and the hot pressing conditions have a great influence on the bonding strength of the bamboo floor.

The bonding strength of bamboo flooring is different from that of wood flooring. It is made by gluing and pressing multiple pieces of bamboo. The quality of the glue, the temperature and pressure of the glue and the time of heat preservation and pressure all have an influence on the quality of the glue. Insufficient bonding strength may deform and crack. The simple way to test the bonding strength is to soak or cook a piece of floor in water. Compare the degree of expansion, deformation and opening and the time required. Whether the bamboo floor will be deformed or degummed has a great relationship with the bonding strength.

9. Cutting head

10. Inspection board color separation

11. Trimming

12. Trimming is a female tenon

13. When producing anti-tenon board, the short head should turn around

14. Sanding

Treat the surface of the slab to make the surface smooth, and fix the thickness of the plain slab

15.Tenoning

Moulders

The bottom and sides of the bamboo board are tenoned.

Double end tenoning

The bamboo floor is tenoned vertically and horizontally.

Tenoning is also commonly known as slotting, which is the concave-convex notch when the floor is spliced, which is the key to ensure the perfect splicing of the floor. The gap between the two floors is tight when the mortise is precision spliced.

16. Paint

In order to prevent moisture in the surrounding environment from invading the bamboo floor, and to make the board surface have anti-pollution, abrasion resistance, and decoration properties, the bamboo floor needs to be painted. Generally after 5 primers (lacquer) and 2 sides (lacquer) coating, the surface of the bamboo floor has been covered with a thick protective paint film. The hardness of the paint film is not the harder the better, it should be moderate in hardness to ensure that the paint film has a certain degree of wear resistance, scratch resistance and toughness.

Paint on the surface of bamboo floor. Floors on the market are divided into bright and semi-matt. The shiny one is the curtain coating process, which is very beautiful, but its face has been worn and peeled off, so it must be carefully maintained when using it. The matt and semi-matt are roller coating processes, with soft color and strong paint adhesion.

There are five bottoms and two sides, seven bottoms and two sides in the market. Choose safe and environmentally friendly high-quality paint when applying the primer, which can not only maintain a healthy home environment, but also achieve beauty, water resistance, and disease resistance. To ensure good paint adhesion, one layer of paint must be sanded. After repeated sanding and painting, the surface of the floor is smooth and flat without bubbles.

17. Finished product inspection

Inspect the finished product. Adhesion, surface effect, abrasion resistance and gloss.

In order to ensure the cutting-edge quality of the floor, the European and American markets implement film inspection, and many domestic companies continue to use this inspection technology. Of course, the relative cost is higher

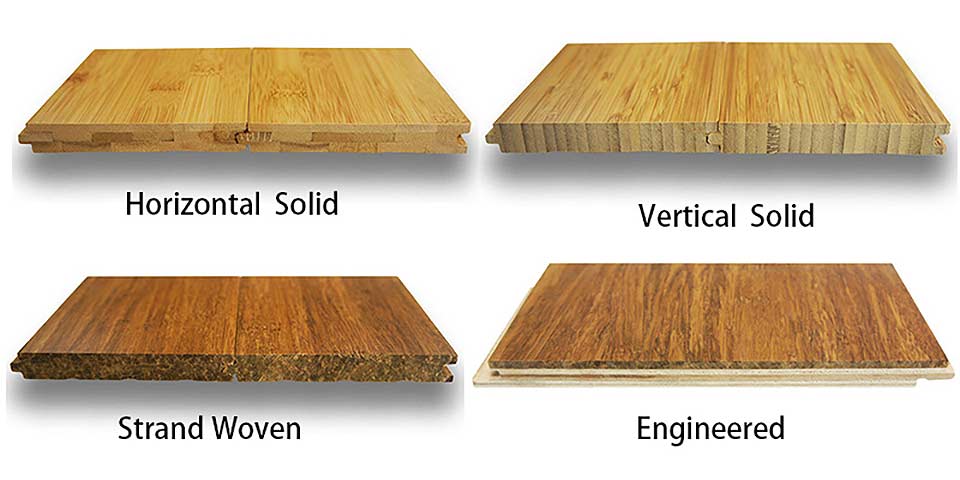

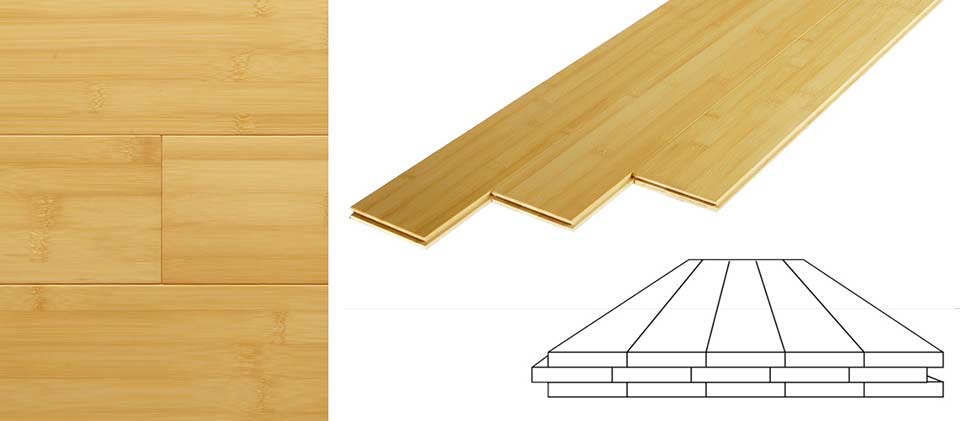

Structure

Natural Bamboo Flooring

Carbonized Bamboo Flooring

Natural Carbonized Bamboo Floor

Bamboo Flooring Advantage

Details Images

Bamboo Flooring Technical Data

| 1) Materials: | 100% Raw Bamboo |

| 2) Colors: | Strand Woven |

| 3) Size: | 1840*126*14mm / 960*96*15mm |

| 4) Moisture content: | 8%-12% |

| 5) Formaldehyde emission: | Up to E1 standard of Europe |

| 6) Varnish: | Treffert |

| 7) Glue: | Dynea |

| 8) Glossiness: | Matt, Semi gloss |

| 9) Joint: | Tongue & Groove (T& G) click ; Unilin+Drop click |

| 10) Supply ability: | 110,000m2 / month |

| 11) Certificate: | CE Certification , ISO 9001:2008, ISO 14001:2004 |

| 12) Packing: | Plastic films with carton box |

| 13) Delivery Time: | Within 25 days after received advance payment |

Click System Available

A: T&G Click

T&G LOCK BAMBOO-Bamboo Florinig

Bamboo T&G -Bamboo Florinig

B: Drop (short side)+ Unilin click (length side)

drop Bamboo Florinig

unilin Bamboo Florinig

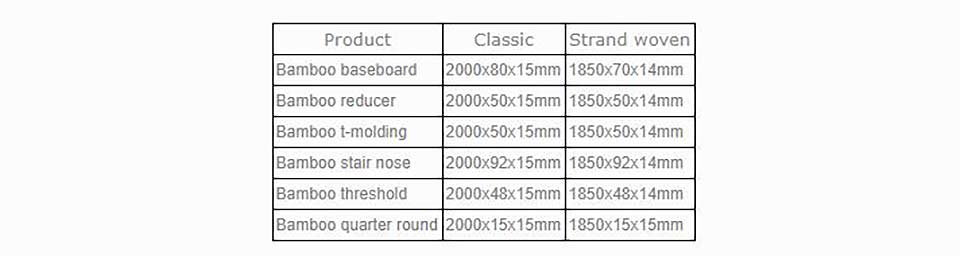

Bamboo flooring package list

| Type | Size | Package | NO Pallet/20FCL | Pallet/20FCL | Size of Box | G.W. | N.W. |

| Carbonized Bamboo | 1020*130*15mm | 20pcs/ctn | 660 ctns/1750.32 sqm | 10 plt, 52ctns/plt,520ctns/1379.04 sqms | 1040*280*165 | 28kgs | 27kgs |

| 1020*130*17mm | 18pcs/ctn | 640 ctns/1575.29 sqm | 10 plt, 52ctns/plt,520ctns/1241.14 sqms | 1040*280*165 | 28kgs | 27kgs | |

| 960*96*15mm | 27pcs/ctn | 710 ctns/ 1766.71 sqm | 9 plt, 56ctns/plt,504ctns/1254.10 sqms | 980*305*145 | 26kgs | 25kgs | |

| 960*96*10mm | 39pcs/ctn | 710 ctns/ 2551.91 sqm | 9 plt, 56ctns/plt,504ctns/1810.57 sqms | 980*305*145 | 25kgs | 24kgs | |

| Strand Woven Bamboo | 1850*125*14mm | 8pcs/ctn | 672 ctn, 1243.2sqm | 970*285*175 | 29 kg | 28 kg | |

| 960*96*15mm | 24pcs/ctn | 560 ctn, 1238.63sqm | 980*305*145 | 26 kg | 25 kg | ||

| 950*136*17mm | 18pcs/ctn | 672ctn, 1562.80sqm | 970*285*175 | 29 kg | 28kg |

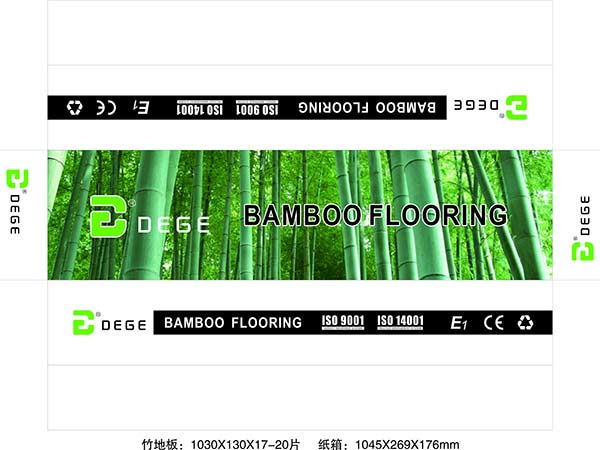

Packaging

Dege Brand Packaging

General Packaging

Transportation

Product Process

Applications

How is bamboo floor installed (detailed version)

How is bamboo floor installed (detailed version)

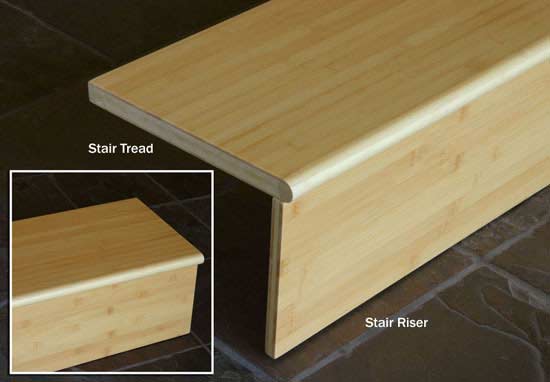

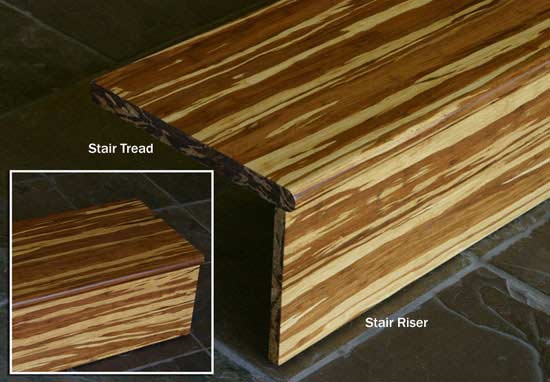

Stair slab

Stair slab

| Characteristic | Value | Test |

| Density: | +/- 1030 kg/m3 | EN 14342:2005 + A1:2008 |

| Brinell hardness: | 9.5 kg/mm² | EN-1534:2010 |

| Moisture content: | 8.3 % at 23°C and 50% relative humidity | EN-1534:2010 |

| Emission class: | Class E1 (LT 0,124 mg/m3, EN 717-1) | EN 717-1 |

| Differential swelling: | 0.17% pro 1% change in moisture content | EN 14341:2005 |

| Abrasion resistance: | 16’000 turns | EN-14354 (12/16) |

| Compressability: | 2930 kN/cm2 | EN-ISO 2409 |

| Impact resistance: | 6 mm | EN-14354 |

| Fire properties: | Class Cfl-s1 (EN 13501-1) | EN 13501-1 |