China OEM Floating Floor - 100% Waterproof Rigid Spc Flooring – DEDGE Detail:

What is SPC VINYL FLOORING ?

SPC VINYL FLOORING is extrusion molding flooring, a new type of technology, similar to 3D printing. Extrusion molding is also called extrusion molding in PVC VINYL FLOORING processing. It means that the material passes through the action between the extruder barrel and the screw, while being plasticized by heat, while being pushed forward by the screw, and continuously passing through the die head grinding tool to make each A method of processing cross-section products or semi-products. The extrusion molding process mainly includes the processes of feeding, melting and plasticizing, extrusion molding, shaping and cooling.

As early as 100 years ago, this kind of extrusion molding has already appeared. In the early stage, it was mainly used for the production of various forms of continuous products such as pipes, sheets, profiles, and wires. Entering the 21st century, used in SPC VINYL FLOOR. As the first batch of SPC FLOORING manufacturers, DEGE has rich production experience and cost control.

Production of Extrusion Spc flooring is an efficient, continuous, low-cost, and wide-adapted molding processing method.

The extrusion process can be divided into two stages:

The first stage is to plasticize the solid plastic and pass it through the die of the SPC sheet under pressure to become a continuum with a section similar to the die shape;

The second stage is to use an appropriate method to make the extruded continuum lose its plastic state and become a solid, while compounding the color film and the anti-friction layer

What is SPC VINYL FLOORING production advantages?

(1) Continuous production, which can produce floors of any length and thickness.

(2) High production efficiency, about 24 tons per day.

(3) Wide application range, construction industry, petrochemical industry, machinery manufacturing, medical equipment, automobile, electronics, aerospace and other industries.

(4) One machine has multiple functions, and one machine can produce any extruded products as long as the abrasive tool is changed.

(5) Simple equipment, simple operation and maintenance.

Structure

Specification

| SPC Flooring Specification | |

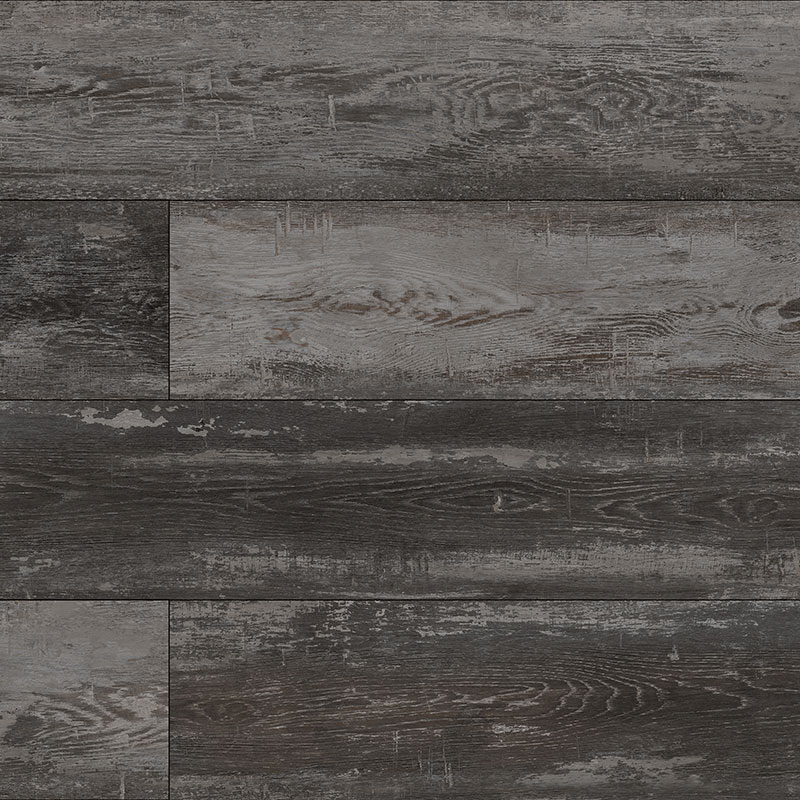

|

Color |

3732-1 |

|

Dimension |

1800*228*5mm+2mm ixpe |

|

Thickness (Optional) |

3.8mm, 4mm, 4.2mm, 5mm, 5.5mm, 6mm |

|

Wear Layer (Optional) |

0.2mm, 0.3mm, 0.5mm |

|

Size(Length*Width) (Optional) |

910*148mm, 1220*178mm, 1500*228mm, 1800*228mm, etc. |

|

Surface (Optional) |

Crystal, Light/Deep Embossed, Real Wood, Handscraped |

|

Core Materi (Optional) |

100% virgin material |

|

Click Syste (Optional) |

Unilin Click, Valinge Lock, Drop Lock(I4F) |

|

Special treatment(Optional) |

V-Groove, Soundproof EVA/IXPE |

|

Installation Method |

Floating |

Size

A. Spc Flooring Plank

B. Spc Flooring Tile

SPC Flooring Backing

Finish Types

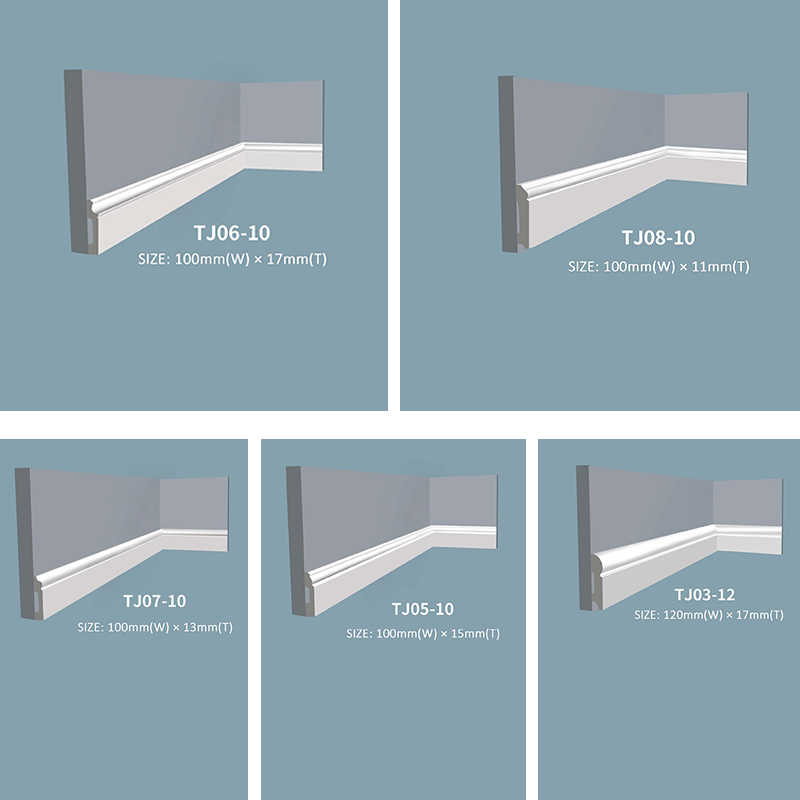

Beveled Edge Types

What is Difference Between the 100% Virgin Spc Flooring and Recycled Spc Flooring ?

Spc Flooring Waterproof Quality Test

Unilin Click

SPC Floor Packing List

| SPC Floor Packing List | |||||||||

| Size | sqm/pc | kgs/sqm | pcs/ctn | sqm/ctn | ctn/pallet | pallet/20ft | sqm/20ft | ctns/20ft | Cargo Weight/20ft |

| 910×148*3.8mm | 0.13468 | 7.8 | 16 | 2.15488 | 63ctn/12pallet, 70ctn/12pallet | 24 | 3439.190 | 1596 | 27300 |

| 910×148*4mm | 0.13468 | 8.2 | 15 | 2.02020 | 63ctn/6pallet, 70ctn/18pallet | 24 | 3309.088 | 1638 | 27600 |

| 910*148*5mm | 0.13468 | 10.2 | 12 | 1.61616 | 70 | 24 | 2715.149 | 1680 | 28000 |

| 910*148*6mm | 0.13468 | 12.2 | 10 | 1.34680 | 70 | 24 | 2262.624 | 1680 | 28000 |

| 1220*148*4mm | 0.18056 | 8.2 | 12 | 2.16672 | 72ctn/10pallet, 78ctn/10pallet | 20 | 3250.080 | 1500 | 27100 |

| 1220*148*5mm | 0.18056 | 10.2 | 10 | 1.80560 | 72 | 20 | 2600.064 | 1440 | 27000 |

| 1220*148*6mm | 0.18056 | 12.2 | 8 | 1.44448 | 78 | 20 | 2253.390 | 1560 | 27900 |

| 1220*178*4mm | 0.21716 | 8.2 | 10 | 2.17160 | 75 | 20 | 3257.400 | 1500 | 27200 |

| 1220*178*5mm | 0.21716 | 10.2 | 8 | 1.73728 | 75 | 20 | 2605.920 | 1500 | 27000 |

| 1220*178*6mm | 0.21716 | 12.2 | 7 | 1.52012 | 70ctn/10pallet, 75ctn/10pallet | 20 | 2204.174 | 1450 | 27300 |

| 600*135*4mm | 0.0810 | 8.2 | 26 | 2.10600 | 72ctn/10pallet, 84ctn/10pallet | 20 | 3285.36 | 1560 | 27400 |

| 600*300*4mm | 0.1800 | 8.2 | 12 | 2.16000 | 72ctn/6pallet, 78ctn/14pallet | 20 | 3291.84 | 1524 | 27400 |

| 1500*225*5mm+2mm IXPE | 0.3375 | 10.6 | 5 | 1.68750 | 64 | 21 | 2268 | 1344 | 24500 |

| 1800*225*5mm+1.5mm IXPE | 0.4050 | 10.5 | 5 | 2.025 | 64 | 18 | 2332.8 | 1152 | 24900 |

| Remarks: The quantity per container can be adjusted according to the limited weight of container for different port. | |||||||||

Advantage

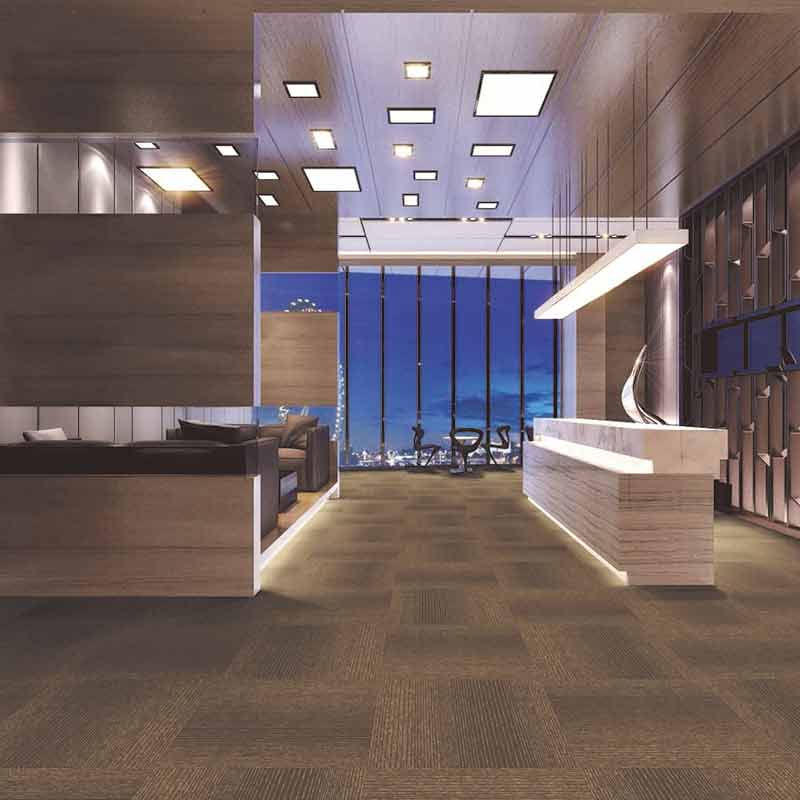

Applications

Blackbutt Spc Flooring Project in Australia – 1

Spotted Gum Spc Flooring Project in Australia – 2

SPC Floor Protection Process

Product detail pictures:

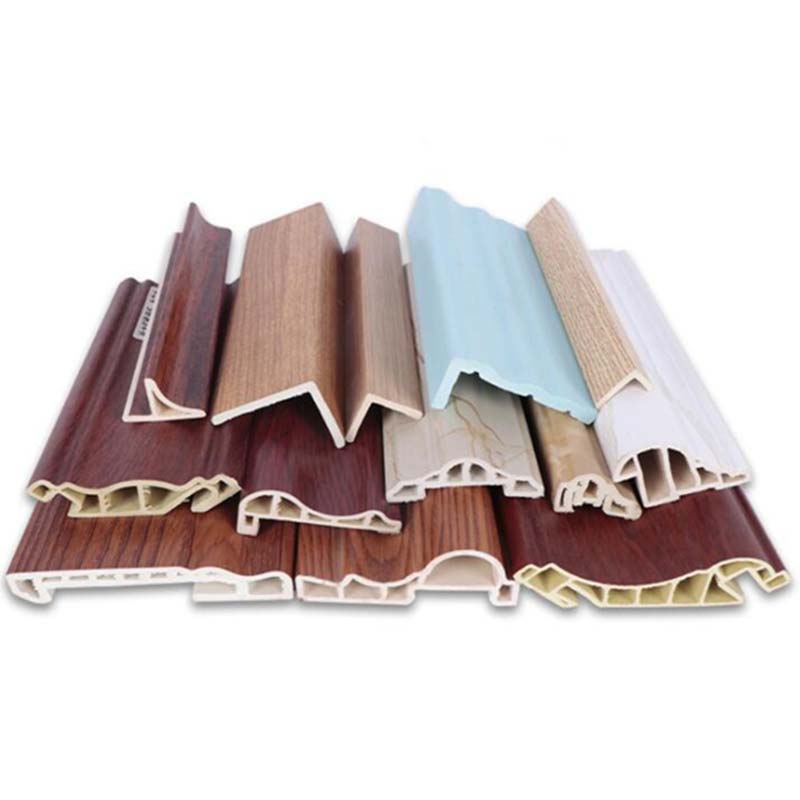

Related Product Guide:

We normally think and practice corresponding on the change of circumstance, and grow up. We aim at the achievement of a richer mind and body and also the living for China OEM Floating Floor - 100% Waterproof Rigid Spc Flooring – DEDGE , The product will supply to all over the world, such as: Russia , Portugal , Frankfurt , Why we can do these? Because: A, We are honest and reliable. Our items have high quality, attractive price, sufficient supply capacity and perfect service. B, Our geographical position has a big advantage . C, Various types: Welcome your inquiry, It might be highly appreciated.

Cooperate with you every time is very successful, very happy. Hope that we can have more cooperation!