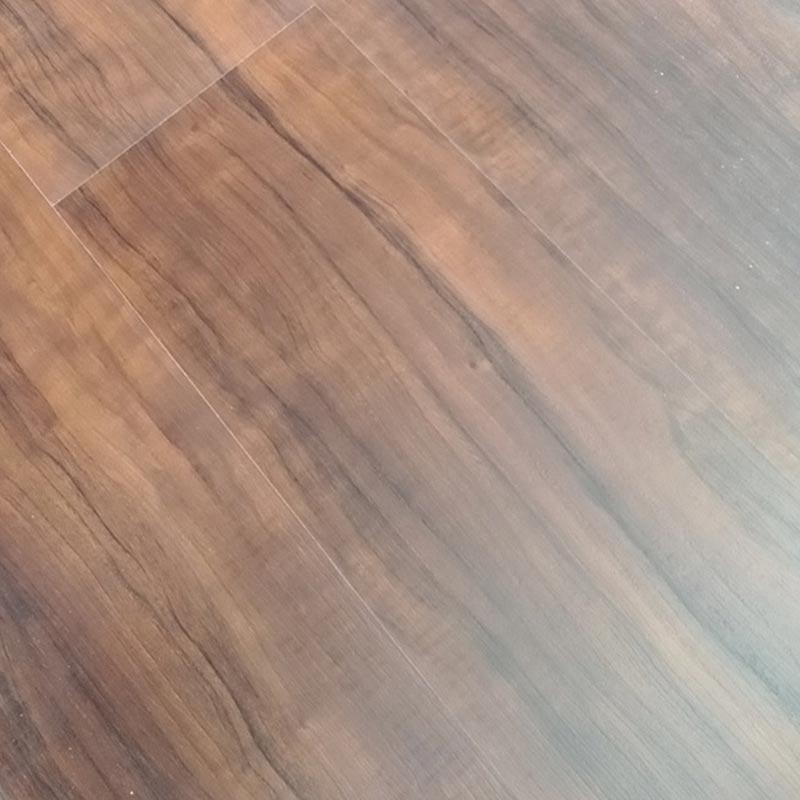

Cheapest Factory China Soild Wpc Decking Floor - u-groove High Glossy Laminate Flooring – DEDGE Detail:

Parameter

| Color | We have several hundreds of color for your choice. | ||

| Thickness | 7mm, 8mm, 10mm, 12mm are available. | ||

| Size | 1218*198,1218*168,1218*148,1218*128, 810*130,810*148,800*400,1200*400,600*100 | ||

| Surface treatment | More than 20 kinds of surface, such as Embossed, Crystal, EIR, Handscraped, Matt, Glossy, Piano etc. | ||

| Edge treatment | Square Edge ,Mold press U-groove , 3 strips U grovoe, V-Groove with painting, bevel painting, waxing, padding, press etc. are provided. | ||

| Special treatment | Press U-groove,Painted V-groove,Waxing, Logo painted on back ,Soundproof EVA/IXPE | ||

| Wear Resistance | AC1,AC2, AC3,AC4, AC5 standard EN13329 | ||

| Base materials | 770 kg /m³,800 kg /m³, 850 kg /m³ and 880 kgs /m³ | ||

| Click system | Unilin Double , Arc , Single , Drop ,Valinge | ||

| Installation Method | Floating | ||

| Formaldehyde Emission | E1<=1.5mg/L, or E0<=0.5mg/L | ||

What is the production process of Laminate Flooring?

Laminate flooring production technology is very simple and easy. It does not require a lot of equipment or labor.

The following is detail :

First,Flooring raw material preparation

Three papers: wear-resistant paper, color paper, balance paper, the three raw materials should be stored in a constant temperature 19℃, constant humidity (relative humidity 55℅-60℅) environment

One substrate: MDF/HDF density board

Second: hot pressing

Adopt low-pressure short-cycle process to heat-press four materials of wear-resistant paper, decorative paper, high-density board and balance paper at one time. Generally, the pressing temperature is about 195℃, the surface pressure is about 3.6Mpa, and the pressing time is 30-40 seconds. Laminate flooring surface is pressed by Upper plate, such as high-gloss floor, you need high-gloss steel plate

Third: a regimen

The hot-pressed slabs are dried before stacking to cool down. After stacking, Laminate flooring plank will be kept for 1-2 days to reduce the temperature of the plates to the ambient temperature. The ideal temperature is about 30°C and not more than 45°C. To

Fourth: cutting board

According to the length and width specifications of the finished laminated floor, plus a processing allowance of 10-11 mm, the large slab is cut into a single floor board according to this size. And put it neatly on the iron tray

Fifth: Second regimen

The cut floor strips should be kept for more than 48 days to release the energy inside the floor and reduce the deformation of the floor. In order to improve the health effect, the side board and the middle material can be kept separately

Sixth: Do click system and Package

The flooring board passes through the slotting machine, and click Lock is completed all around. The quality inspector conducts height difference and triangle seam inspection. After passing the inspection, it is packaged and put into storage.

Surface Available

Click Systems Available

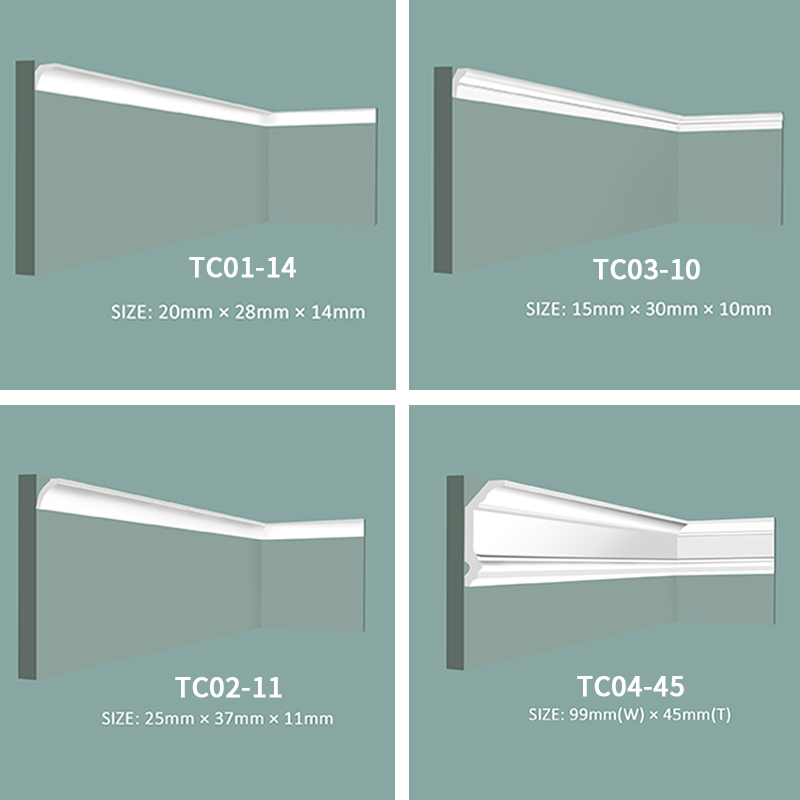

Joint Available

Back Colors Available

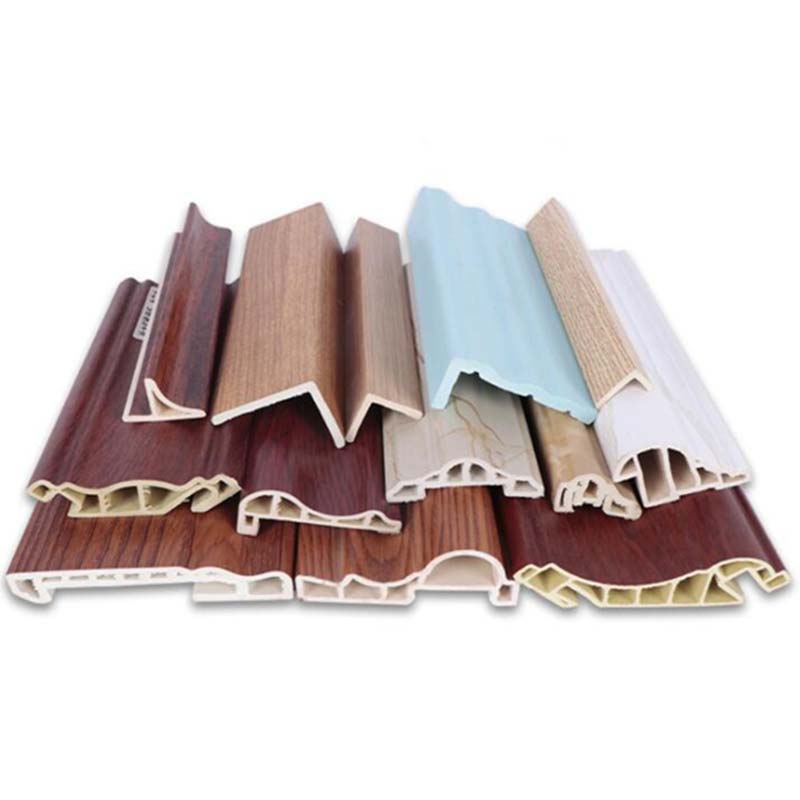

Special Treatments Available

Quality Test

Laminate Flooring Package Details

| Packing List | ||||||||

| Size | pcs/ctn | m2/ctn | ctns/pallet | plts/20′cont | ctns/20′cont | kg/ctn | m2/20′cont | kgs/20′cont |

| 1218*198*7mm | 10 | 2.41164 | 70 | 20 | 1400 | 15 | 3376.296 | 21400 |

| 1218*198*8mm | 10 | 2.41164 | 60 | 20 | 1200 | 17.5 | 2893.97 | 21600 |

| 1218*198*8mm | 8 | 1.929312 | 70 | 20 | 1400 | 14 | 2701 | 20000 |

| 1218*198*10mm | 9 | 2.170476 | 55 | 20 | 1100 | 17.9 | 2387.5236 | 20500 |

| 1218*198*10mm | 7 | 1.688148 | 70 | 20 | 1400 | 13.93 | 2363.4072 | 20500 |

| 1218*198*12mm | 8 | 1.929312 | 50 | 20 | 1000 | 20 | 1929.312 | 20600 |

| 1218*198*12mm | 6 | 1.446984 | 65 | 20 | 1300 | 15 | 1881 | 19900 |

| 1215*145*8mm | 12 | 2.1141 | 60 | 20 | 1200 | 15.5 | 2536 | 19000 |

| 1215*145*10mm | 10 | 1.76175 | 65 | 20 | 1300 | 14.5 | 2290.275 | 19500 |

| 1215*145*12mm | 10 | 1.76175 | 52 | 20 | 1040 | 17.5 | 1832 | 18600 |

| 810*130*8mm | 30 | 3.159 | 45 | 20 | 900 | 21 | 2843.1 | 19216 |

| 810*130*10mm | 24 | 2.5272 | 45 | 20 | 900 | 21 | 2274.48 | 19216 |

| 810*130*12mm | 20 | 2.106 | 45 | 20 | 900 | 21 | 1895.4 | 19216 |

| 810*150*8mm | 30 | 3.645 | 40 | 20 | 800 | 24.5 | 2916 | 19608 |

| 810*150*10mm | 24 | 2.916 | 40 | 20 | 800 | 24.5 | 2332.8 | 19608 |

| 810*150*12mm | 20 | 2.43 | 40 | 20 | 800 | 24.5 | 1944 | 19608 |

| 810*103*8mm | 45 | 3.75435 | 32 | 24 | 768 | 27.2 | 2883 | 21289.6 |

| 810*103*12mm | 30 | 2.5029 | 32 | 24 | 768 | 26 | 1922 | 20368 |

| 1220*200*8mm | 8 | 1.952 | 70 | 20 | 1400 | 14.5 | 2732 | 20700 |

| 1220*200*12mm | 6 | 1.464 | 65 | 20 | 1300 | 15 | 1903 | 19900 |

| 1220*170*12mm | 8 | 1.6592 | 60 | 20 | 1200 | 17 | 1991 | 20800 |

Product detail pictures:

Related Product Guide:

We know that we only thrive if we can guarantee our combined price tag competiveness and top quality advantageous at the same time for Cheapest Factory China Soild Wpc Decking Floor - u-groove High Glossy Laminate Flooring – DEDGE , The product will supply to all over the world, such as: Sacramento , Brazil , Denver , Till now, the goods list has been updated regularly and attracted clients from around the globe. Detailed facts is often obtained in our web-site and you'll be served with premium quality consultant service by our after-sale group. They are going to help you get comprehensive acknowledge about our products and make a satisfied negotiation. Company go to to our factory in Brazil is also welcome at any time. Hope to obtain your inquiries for any pleased co-operation.

The company has rich resources, advanced machinery, experienced workers and excellent services, hope you keep improving and perfecting your products and service, wish you better!

-

Leading Manufacturer for Commercial Vinyl Floor...

-

Online Exporter Spc Vinyl - Interior PS/Polyst...

-

Super Purchasing for Lvt - Wpc Decorative line...

-

Top Quality External Cladding Panels - 100% Wp...

-

Top Suppliers Wpc Outdoor Wall Panel - Wood Te...

-

New Fashion Design for Spc Vinyl Plank Flooring...