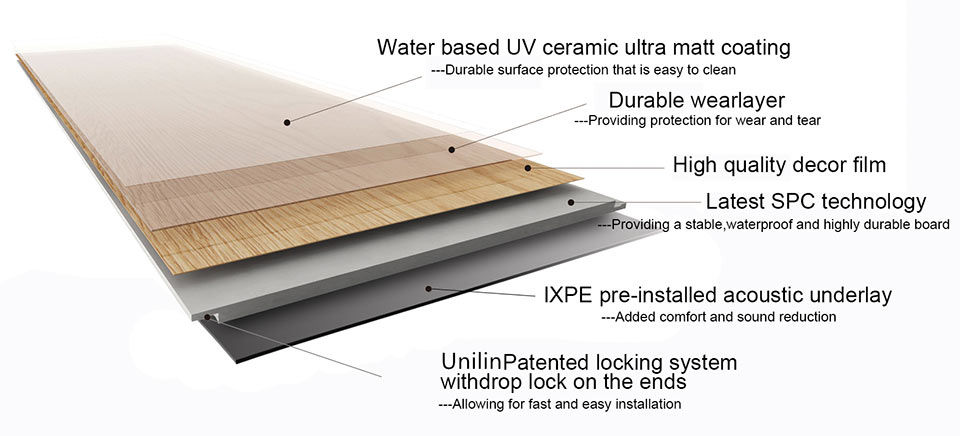

Structure

Details Images

Specification

| SPC Flooring Specification | |

| Color Code | 87024 |

| Thickness | 3.8mm, 4mm, 4.2mm, 5mm, 5.5mm, 6mm |

| Wear Layer | 0.2mm, 0.3mm, 0.5mm |

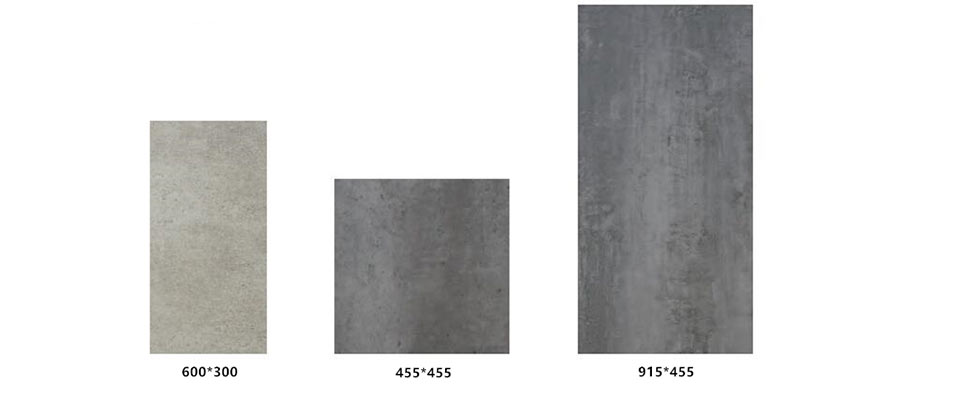

| Size | 600mm*300mm |

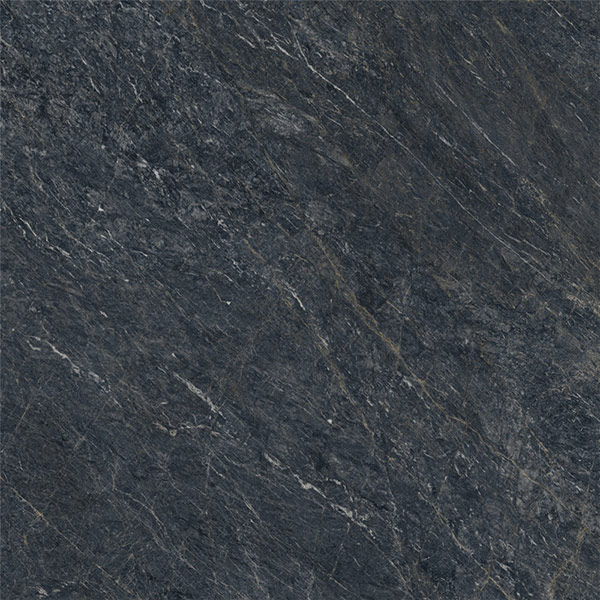

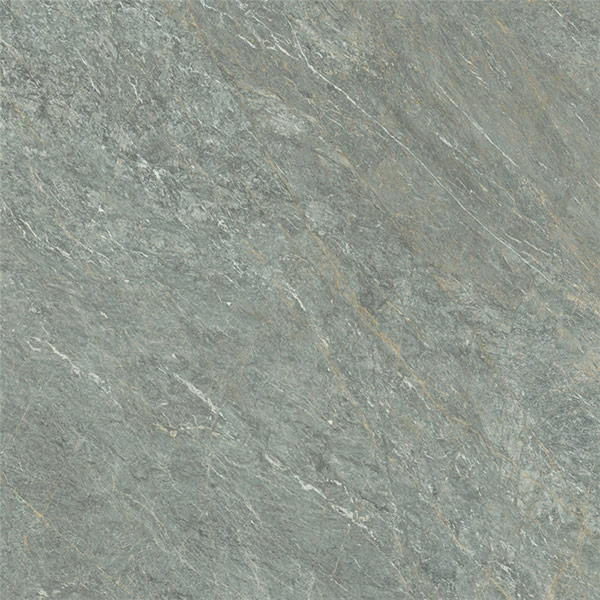

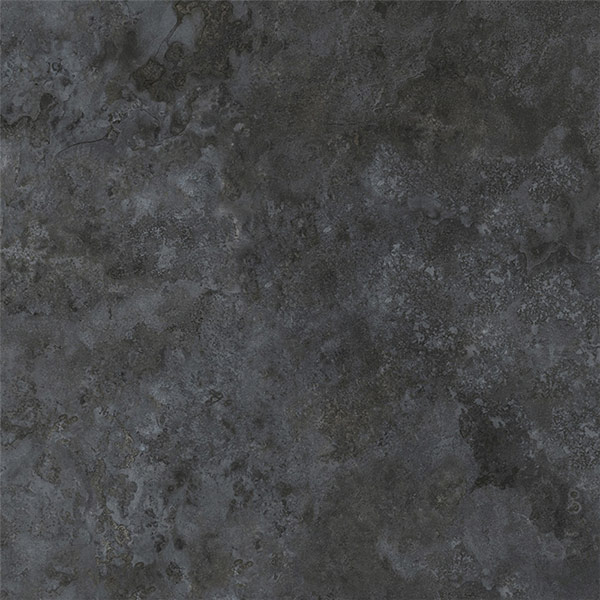

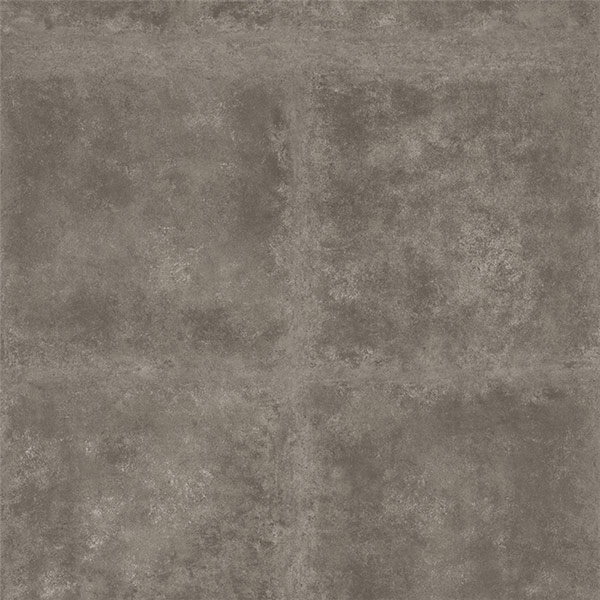

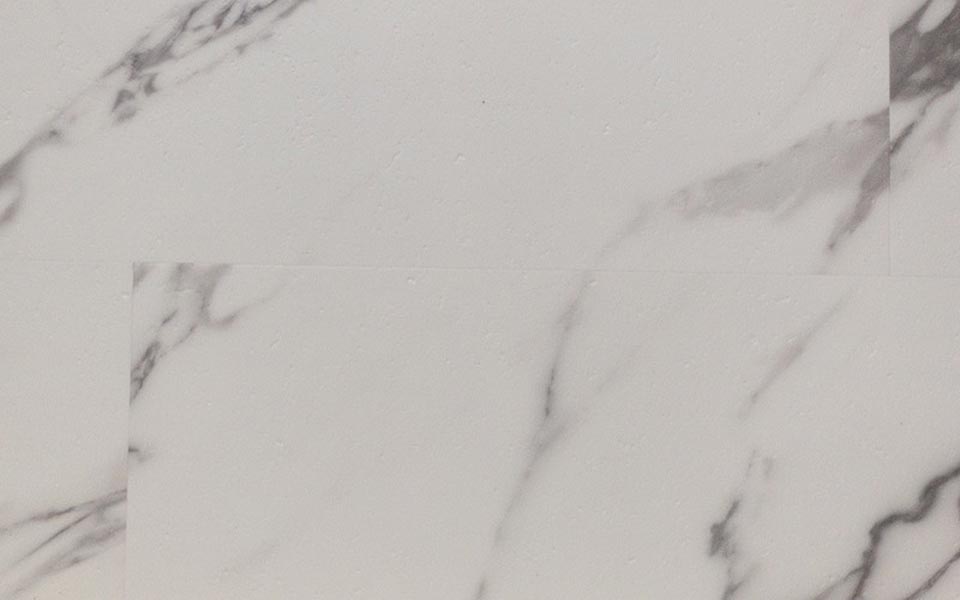

| Surface | Marble, Leather,Stone |

| Core Material | 100% virgin material |

| Click System | Unilin Click, Drop Lock(I4F) |

| Special treatment | V-Groove, Soundproof EVA/IXPE |

| Installation Method | Floating |

How to clean and maintain Spc Vinyl ?

SPC VINYL flooring is more and more popular with consumers due to its excellent performance, and we can see traces of SPC flooring in many different occasions. Choosing VINYL flooring reflects a person's character, but do you know how to maintain PVC flooring? Today, I will share with you the maintenance and maintenance of PVC flooring.

One: Purpose of cleaning and maintenance of spc vinyl floor

1. Improve appearance

Timely remove the dirt generated in daily use, so that the elastic floor fully demonstrates its extraordinary appearance and natural gloss.

2. Protect the floor

The elastic floor is protected from accidental chemicals, cigarette butts, shoe marks, oil and water, etc., and mechanical abrasion on the surface is minimized, so that the durability of the floor itself can be fully utilized, thereby extending the service life of the vinyl floor.

3. Convenient care

Due to the tight surface structure and special treatment of the elastic floor, attention to daily cleaning and maintenance can make the floor easier to care and prolong its service life.

Two: Special dirt management methods for spc floor

As we all know, SPC PVC flooring has the advantages of antibacterial, high elasticity, wear-resistant and non-slip, waterproof and moisture-proof, and convenient construction. Scientific and reasonable cleaning and maintenance can not only keep the floor bright and tidy, but also increase the service life of the floor.

1. If there is dust, particles or impregnating substances on the floor surface, please clean the floor in time to prevent these debris from damaging the floor surface and causing unnecessary trouble.

2. If part of the floor surface is severely stained, you can use a neutral reagent to clean it, and then scrub the floor surface with a damp cloth. Do not use a wire brush or other sharp brushes to scrub the floor to avoid damage to the surface.

3. When you accidentally drip paint, solvents or medicines on the floor, you should promptly remove them with alcohol. If you use acid or some strong solvents, it may enlarge the dyed area or cause discoloration.

4. When you use a rag with a lot of moisture to clean, pay special attention to the water droplets entering from the horizontal grain or connecting part, causing the connecting part to open.

5. Do not use a moist mop when cleaning the waxed floor to prevent sewage from attaching to the wax surface, causing the wax layer to rise. You can use a slightly damp mop to clean the dust on the surface of the floor, and focus on cleaning the heavily polluted areas.

6. If oil pollution occurs, you can clean it with a neutral agent to keep the floor surface clean.

Although the SPC VINYL floor has a certain degree of fire resistance, it may also be burnt. Therefore, when using the SPC PVC floor, please avoid placing some heat-conducting items directly on the surface of the PVC floor to avoid damage to the floor.

Three: pvc floor care attention points

1. Avoid pollutants: Although the SPC VINYL floor is easy to clean, it should be avoided to bring pollutants into the room to avoid the situation that cannot be cleaned and pollute and damage the floor.

2. Avoid scratches by sharp objects and hard objects: Avoid bringing hard and sharp objects into the room, especially when there are metal sharp objects at the bottom, do not drag on the floor to prevent the floor from being injured;

3. Avoid water immersion: avoid a large amount of water staying on the floor surface for a long time. If the floor is soaked for a long time, it may penetrate under the floor and cause the floor to melt and lose its adhesion. It may also cause the floor pollution by the protective wax moisture layer on the surface Sewage may penetrate into the interior of the floor and cause discoloration of the floor;

4. Avoid burning and scalding: Although the Golden Elephant Resilient Floor is a fire-retardant floor (Class B1), it does not mean that the floor will not be burned by fireworks. Therefore, when people use SPC PVC flooring, do not use burning cigarette butts, mosquito coils, Live irons and high-temperature metal objects are placed directly on the floor to prevent damage to the floor;

5. Avoid strong light: Avoid direct strong light, avoid ultraviolet radiation, and prevent discoloration and fading of the floor.

Size

A. Spc Flooring Plank

B. Spc Flooring Tile

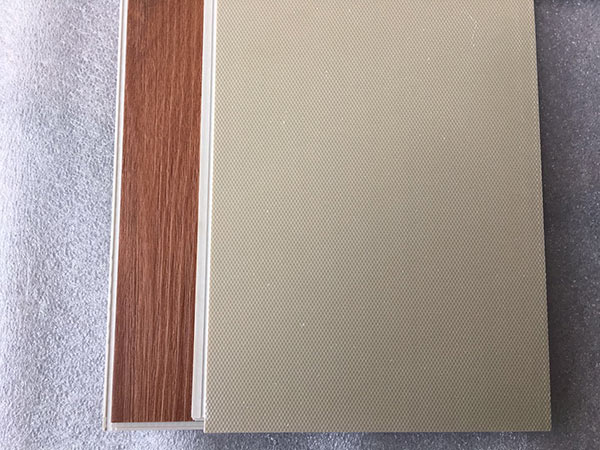

SPC Flooring Backing

IXPE Backing

Plain EVA Backing

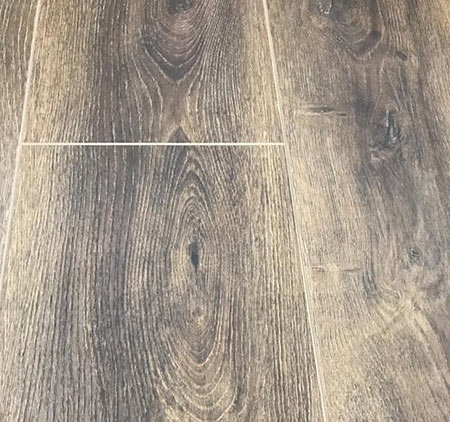

Finish Types

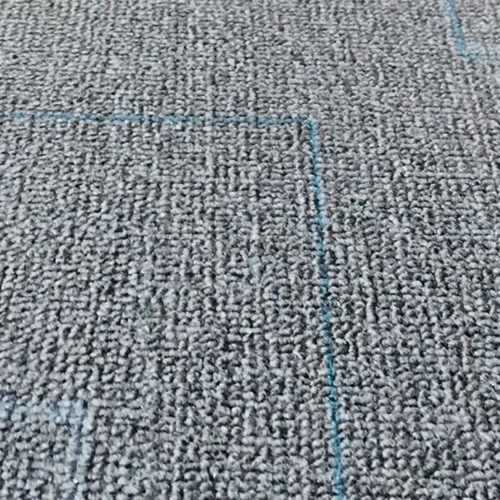

Carpet Surface

Crystal Surface

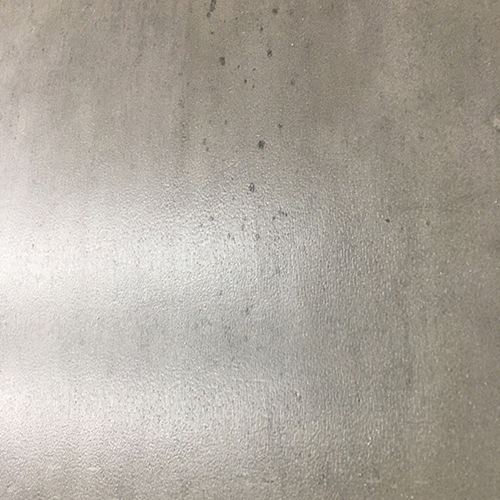

Deep Embossed Surface

Handscraped Spc Flooring

Leather Surface

Light Embossed

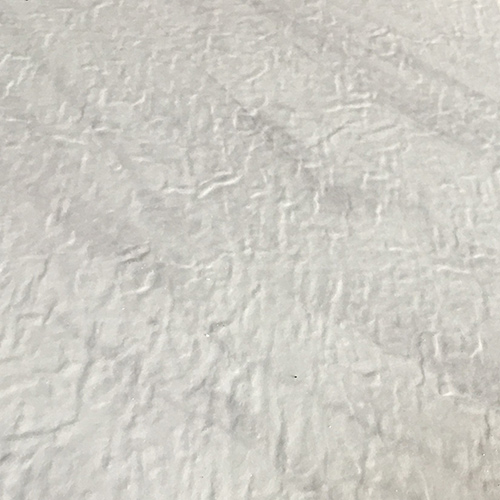

Marble Surface

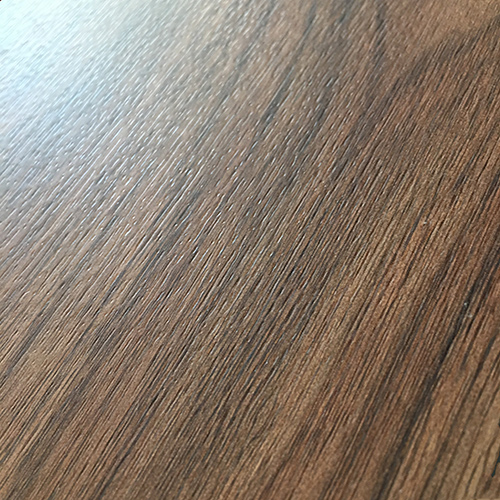

Real Wood

Beveled Edge Types

Micro V-Groove Beveled

V Groove Painted

What is Difference Between the 100% Virgin Spc Flooring and Recycled Spc Flooring ?

Spc Flooring Waterproof Quality Test

Unilin Click

Unilin Click 1

Unilin Click 2

SPC Floor Packing List

| SPC Floor Packing List | |||||||||

| Size | sqm/pc | kgs/sqm | pcs/ctn | sqm/ctn | ctn/pallet | pallet/20ft | sqm/20ft | ctns/20ft | Cargo Weight/20ft |

| 910×148*3.8mm | 0.13468 | 7.8 | 16 | 2.15488 | 63ctn/12pallet, 70ctn/12pallet | 24 | 3439.190 | 1596 | 27300 |

| 910×148*4mm | 0.13468 | 8.2 | 15 | 2.02020 | 63ctn/6pallet, 70ctn/18pallet | 24 | 3309.088 | 1638 | 27600 |

| 910*148*5mm | 0.13468 | 10.2 | 12 | 1.61616 | 70 | 24 | 2715.149 | 1680 | 28000 |

| 910*148*6mm | 0.13468 | 12.2 | 10 | 1.34680 | 70 | 24 | 2262.624 | 1680 | 28000 |

| 1220*148*4mm | 0.18056 | 8.2 | 12 | 2.16672 | 72ctn/10pallet, 78ctn/10pallet | 20 | 3250.080 | 1500 | 27100 |

| 1220*148*5mm | 0.18056 | 10.2 | 10 | 1.80560 | 72 | 20 | 2600.064 | 1440 | 27000 |

| 1220*148*6mm | 0.18056 | 12.2 | 8 | 1.44448 | 78 | 20 | 2253.390 | 1560 | 27900 |

| 1220*178*4mm | 0.21716 | 8.2 | 10 | 2.17160 | 75 | 20 | 3257.400 | 1500 | 27200 |

| 1220*178*5mm | 0.21716 | 10.2 | 8 | 1.73728 | 75 | 20 | 2605.920 | 1500 | 27000 |

| 1220*178*6mm | 0.21716 | 12.2 | 7 | 1.52012 | 70ctn/10pallet, 75ctn/10pallet | 20 | 2204.174 | 1450 | 27300 |

| 600*135*4mm | 0.0810 | 8.2 | 26 | 2.10600 | 72ctn/10pallet, 84ctn/10pallet | 20 | 3285.36 | 1560 | 27400 |

| 600*300*4mm | 0.1800 | 8.2 | 12 | 2.16000 | 72ctn/6pallet, 78ctn/14pallet | 20 | 3291.84 | 1524 | 27400 |

| 1500*225*5mm+2mm IXPE | 0.3375 | 10.6 | 5 | 1.68750 | 64 | 21 | 2268 | 1344 | 24500 |

| 1800*225*5mm+1.5mm IXPE | 0.4050 | 10.5 | 5 | 2.025 | 64 | 18 | 2332.8 | 1152 | 24900 |

| Remarks: The quantity per container can be adjusted according to the limited weight of container for different port. | |||||||||

Advantage

SPC Floor Anti-scracth Test

SPC Floor Fireproof Test

SPC Floor Waterproof Test

Applications

Blackbutt Spc Flooring Project in Australia – 1

Spotted Gum Spc Flooring Project in Australia – 2

SPC Floor Protection Process

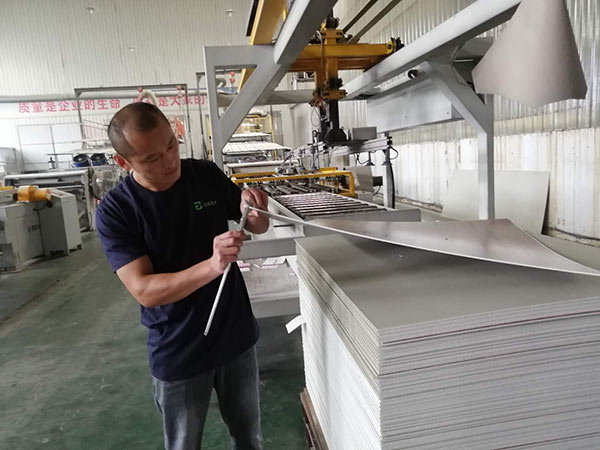

1 Workshop

4 SPC Health Board

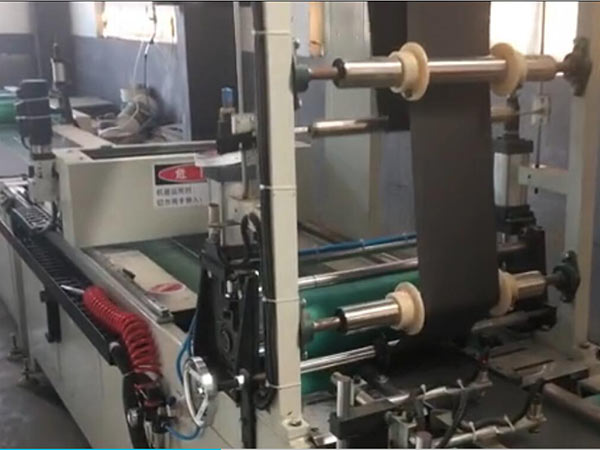

7 SPC Click Macking Machine

10 Warehouse

2 SPC Coextrusion Machine

5 SPC Quality Test

8 Foam Adding Machine

11 Loading

3 UV Machine

6 SPC Cutting Machine/strong>

9 Laboratory

A. Drop Click Spc Flooring Installation

A. Drop Click Spc Flooring Installation

B. Unilin Click Spc Flooring Installation

B. Unilin Click Spc Flooring Installation

SPC FLOORING INSTALLATION METHOD

SPC FLOORING INSTALLATION METHOD

1. First, determine how you want the flooring to run. Typically for plank products, the flooring runs the length of the room. There may be exceptions since it is all a matter of preference.

2. To avoid narrow plank widths or short planks lengths near the walls/ doors, it’s important to do some pre-planning. Using the width of the room, calculate how many full boards will fit into the area and how much space remains that will need to be covered by partial planks. Divide the remaining space by two to calculate the width of the partial planks. Do the same along the length.

3. Note that the first row of planks does not need to be trimmed in width, it will be necessary to cut off the unsupported tongue so that a clean, solid edge is toward the wall.

4. 8mm expansion gaps should be kept from the wall during the installation. This will allow space the natural expansion gaps and contraction of the planks.

5. The planks should be installed from right to left. From the top right corner of the room, put the first plank in place so that both the head and side seam grooves are exposed.

6. Install the second plank in the first row by angling the short side tongue into the long side groove of the first plank.

7. To start the second row, cut a plank that is at least 152.4mm shorter than the first plank by inserting the long side tongue into the groove of the plank in the first row.

8. Install the second plank in the second row by inserting the short side tongue into the previously installed first plank long side groove.

9. Align the plank so the short side tongue tip is positioned just over the groove lip of the plank in the first row.

10. Using gentle force and at a 20-30 degree angle, push the short side tongue into the groove of the adjourning plank by sliding along the long side seam. You may need to lift the plank to the right of it slightly to allow for the “sliding” action.

11. The remaining planks can be installed in the room using the same technique. Make sure the required expansion gaps are maintained against all fixed vertical parts (such as walls, doors, cabinets etc).

12. The planks can be cut easily with a utility knife, just score the top of the plank and snap the plank in two.

Spc flooring installation design

Spc flooring installation design

| Characteristic | Test Specification and Result |

| Sizes (in inches) | 6×36; 6×48; 7×48; 8×48; 9×48; 12×24; 12×48; 12×36; 18×36 |

| Thickness | 3.8mm, 4.0mm, 4.5mm, 5.0mm, 5.5mm, 6.0mm |

| Attachment / Backing | 1.5mm or 2.0mm IXPE and EVA |

| Squareness | ASTM F2055 – Passes – 0.010 in. max |

| Size and Tolerance | ASTM F2055 – Passes – +0.016 in per linear foot |

| Thickness | ASTM F386 – Passes – Nominal +0.005 in. |

| Flexibility | ASTM F137 – Passes – ≤1.0 in., no cracks or breaks |

| Dimensional Stability | ASTM F2199 – Passes – ≤ 0.024 in. per linear foot |

| Heavy Metal Presence / Absence | EN 71-3 C — Meets Spec. (Lead, Antimony, Arsenic, Barium, Cadmium, Chromium, Mercury and Selenium). |

| Smoke Generation Resistance | EN ISO 9239-1 (Critical Flux) Results 9.1 |

| Smoke Generation Resistance, Non-Flaming Mode | EN ISO |

| Flammability | ASTM E648- Class 1 Rating |

| Residual Indentation | ASTM F1914 – Passes – Average less than 8% |

| Static Load Limit | ASTM-F-970 Passes 1000psi |

| Requirements for Wear Group pr | EN 660-1 Thickness Loss 0.30<I<0.60 prEN 660-2 Volume Los 7.5<F <15.0 |

| Slip Resistance | ASTM D2047 – Passes – > 0.6 Wet, 0.6 Dry |

| Resistance to Light | ASTM F1515 – Passes – ∧E ≤ 8 |

| Resistance to Heat | ASTM F1514 – Passes – ∧E ≤ 8 |

| Electrical Behavior (ESD) | EN 1815: 1997 2,0 kV when tested at 23 C+1 C |

| Underfloor Heating | Suitable for installing over under floor heating. |

| Curling After Exposure to Heat | EN 434 < 2mm pass |

| Recycled Vinyl Content | Approximately 40% |

| Recyclability | Can be recycled |

| Product Warranty | 10-Year Commercial & 15-Year Residential |

| Floorscore Certified | Certificate Provided Upon Request |