What is Wood Plastic Composite decking?

Wood Plastic Composite decking materials are a new type of environmentally friendly building materials that have emerged recently. The raw materials used in wood-plastic products can be used as substrates such as waste plastics and waste wood, agricultural and forestry orange stems and other plant fibers, without any additional harmful ingredients. Moreover, it can be recycled and reused, and it can be called a novel product of environmental protection, energy saving, and resource recycling in the true sense.

When composite decking materials are used as building templates, they can greatly improve construction efficiency and shorten construction time. Compared with traditional formwork, wood-plastic formwork can save about 30% in single comprehensive use cost, and auxiliary cost can be reduced by about 40%, which directly reduces project construction cost by nearly 5%.

Advantages:

a. Moisture-proof and mildew-proof. Everyone knows that solid wood flooring or anticorrosive wood flooring used outdoors is sensitive to moisture and moisture. Prolonged soaking or humid environment will cause the solid wood flooring to crack, mold, swell, and deform. Wood (wood-plastic) flooring fundamentally solves this shortcoming of solid wood flooring. It is more outstanding in terms of waterproof, moisture-proof and mildew-proof performance. Therefore, plastic wood flooring can be used in environments where traditional anticorrosive wood flooring cannot be applied.

b. Rich styles and colors. Compared with traditional anticorrosive wood flooring, plastic wood flooring not only has natural wood and texture, but also has richer colors, which can make outdoor landscape decoration more personalized.

c. Anti-insect and ants: solid wood flooring will be eroded by insects or termites, and plastic wood flooring can effectively prevent pests and ants, so the service life will be longer than traditional anticorrosive wood flooring.

d. Strong plasticity: There are many styles and colors of plastic wood flooring, so it is suitable for various decoration styles and can achieve personalized modeling, so its plasticity is much better than ordinary anticorrosive wood flooring.

e. Low-carbon environmental protection and zero formaldehyde: Plastic wood flooring does not contain heavy metal substances, and its formaldehyde content meets EO standards.

f. Fire prevention: Plastic wood flooring can be effectively flame retardant, and its fire rating reaches B1. It can extinguish itself away from the fire and does not produce any toxic and harmful gases.

g. Easy installation: The installation of plastic wood flooring is simple and convenient, does not require complicated installation processes, and can save installation time and labor costs.

Disadvantages:

a. Thermal expansion and contraction: If the temperature difference between day and night in the use environment is large, the surface layer and core layer of the plastic wood floor will have uneven temperature changes, which will easily cause expansion and deformation, which will also affect the service life of the plastic wood floor. Make an impact.

b. Surface fading: In order to save the cost of formula and production process, some small plastic wood material factories will reduce the use of antioxidants, coupling agents and other related reinforcing additives. In this case, plastic wood floors are Problems such as serious fading, brittleness and cracking of materials, swelling and moldy will occur

Structure

Details Images

WPC Decking Specifications

| Material | 32% HDPE, 58% Wood Powder, 10% Chemical Additives |

| Size | 138*39mm, 140*25/30mm, 145*25/30mm, 146*24mm |

| Length | 2200mm, 2800mm, 2900mm or Customized |

| Color | Red(RW), Maple(MA), Reddish Brown(RB), Teak(TK), Wood(SB), Dark Coffee(DC), Light Coffee(LC), Light Grey(LG), Green(GN) |

| Surface Treatment | Sanded, Thin Grooves, Medium Grooves, Thick Grooves, Wire-brushed, Wood Grain, 3D Embossed, Bark Grain, Ring Pattern |

| Applications | Garden, Lawn, Balcony, Corridor, Garage, Pool Surrounds, Beach Road, Scenic, etc. |

| Lifespan | Domestic: 15-20 years, Commercial: 10-15 years |

| Technical Parameter |

Flexural failure load: 3876N (≥2500N) Water absorption:1.2% (≤10%) Fire-retardant: B1 Grade |

| Certificate | CE, SGS, ISO |

| Packing | About 800sqm/20ft and about 1300sqm/40HQ |

Color Available

WPC Decking Surfaces

Package

Product Process

Applications

Project 1

Project 2

Project 3

Wpc Decking Accessories

Wpc Decking Accessories

L Edge

L Edge  Plastic clips

Plastic clips  Stainless steel clips

Stainless steel clips  Wpc keel

Wpc keel

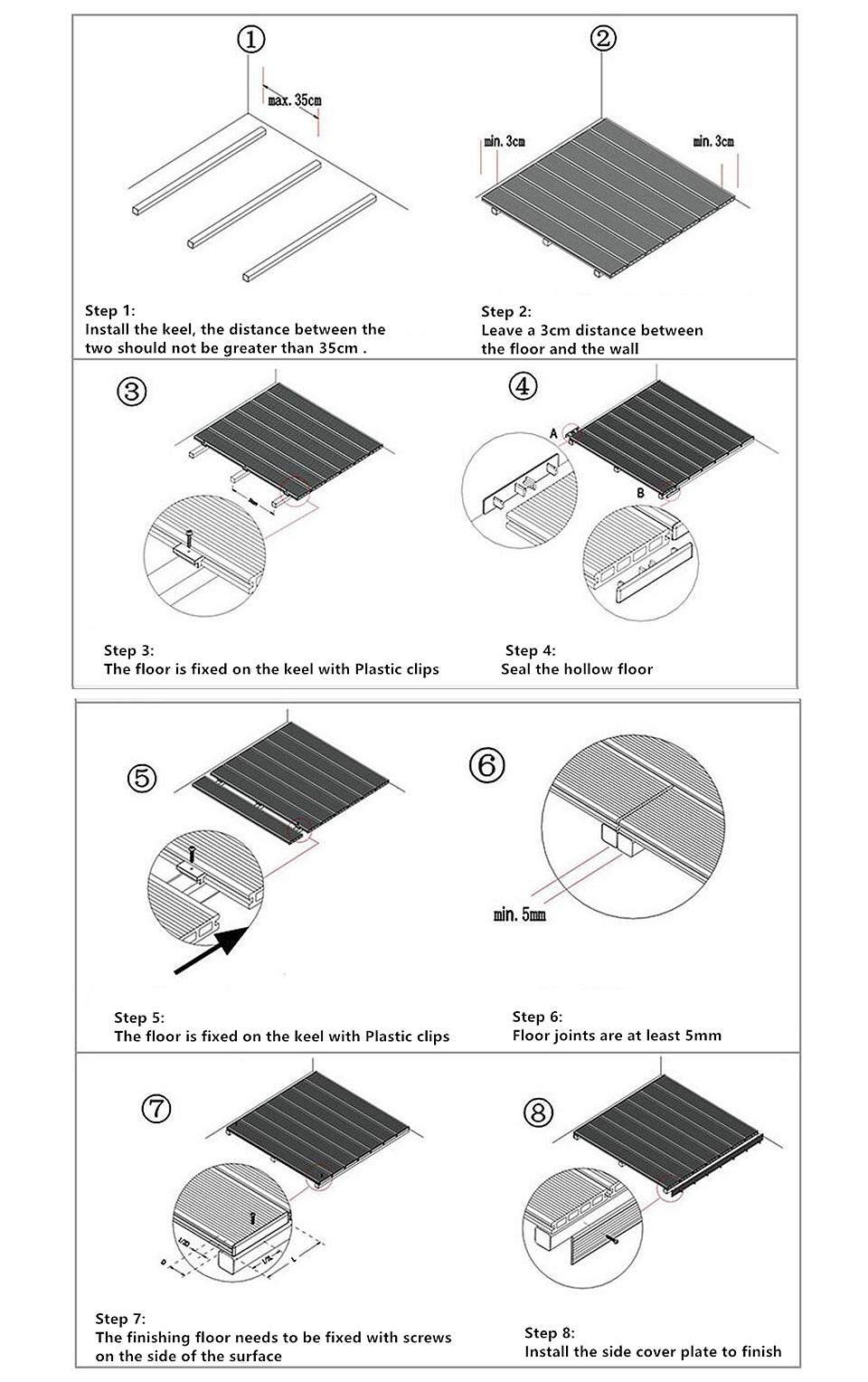

Wpc Decking Installation Steps

Wpc Decking Installation Steps

| Density | 1.35g/m3 (Standard: ASTM D792-13 Method B) |

| Tensile strength | 23.2 MPa (Standard: ASTM D638-14) |

| Flexural strength | 26.5Mp (Standard: ASTM D790-10) |

| Flexural Modulus | 32.5Mp (Standard: ASTM D790-10) |

| Impact strength | 68J/m (Standard: ASTM D4812-11) |

| Shore hardness | D68 (Standard: ASTM D2240-05) |

| Water absorption | 0.65%(Standard: ASTM D570-98) |

| Thermal expansion | 42.12 x10-6 (Standard: ASTM D696 – 08) |

| Slip resistant | R11 (Standard: DIN 51130:2014) |