Carbonized Bamboo Floor

How to choose Floating Bamboo Flooring?

Choose Best Floating Bamboo Flooring for your home , you need know how select.

Below is some Professional advice :

1.First look at the face:

There are no bubbles in the paint, whether it is fresh and bright, whether the bamboo joints are too dark, and whether there are glue lines on the surface (one by one uniform and straight line, the machining process is not fine, the heat pressure is not caused by other reasons) and then check whether there are cracks around , Whether there are any traces of ash. Whether it is clean and tidy, and then see if there is any remaining bamboo on the back, and whether it is clean and tidy. After reading everything, we need to inspect the goods to see if there is any difference between the sample and the actual product. The last item is installation. If the keel needs to be punched, it is about 30 cm in accordance with the standard. The standard plate needs four keels.

2.See features:

The color difference is small, because the growth radius of bamboo is much smaller than that of trees, and it is not seriously affected by sunlight, and there is no obvious difference between yin and yang. Therefore, the bamboo floor has rich bamboo patterns, and the color is uniform; the surface hardness is also one of the bamboo floors. advantage. Because the bamboo floor is a plant crude fiber structure, its natural hardness is more than twice that of wood, and it is not easy to deform. The theoretical service life is up to 20 years. In terms of stability, bamboo flooring shrinks and expands less than solid wood flooring. But in terms of actual durability, bamboo flooring also has shortcomings: delamination will occur under the influence of sunlight and humidity. Because of its higher specific heat and high density, its heat will not be lost in winter. Therefore, bamboo flooring has the performance of keeping warm.

3.Look at environmental protection:

For laminate flooring, the most important criterion for floor environmental protection is the amount of formaldehyde released. Regarding the limitation of formaldehyde emission standards, environmental protection in the floor industry has experienced three technological revolutions of E1, E0, and FCF. In the early stage, the formaldehyde emission standard of wood-based panels is E2 (formaldehyde emission ≤30mg/100g), and its formaldehyde emission limit is very loose. Even if it is a product that meets this standard, its formaldehyde content may exceed E1 artificial More than three times the size of the board, seriously endangering human health, so it must not be used for home decoration. Therefore, there was the first environmental protection revolution. In this environmental protection revolution, the floor industry implemented the E1 environmental protection standard, that is, the formaldehyde emission is ≤1.5㎎/L. Although it basically does not pose a threat to the human body, there are still residues in the floor. Many free formaldehyde. The flooring industry has begun the second environmental protection revolution, and introduced the E0 environmental protection standard, which reduced the floor formaldehyde emission to 0.5㎎/L.

4.Look at quality

Good floor should choose good material, good material should be natural, high and moderate density. Some people think that the higher the density of wood-based panels, the better. In fact, it is not. Too high density has a high water swelling rate, which can easily cause dimensional changes and lead to floor deformation. Secondly, it is necessary to rely on advanced flooring production lines and equipment and rigorous technology to produce first-class flooring.

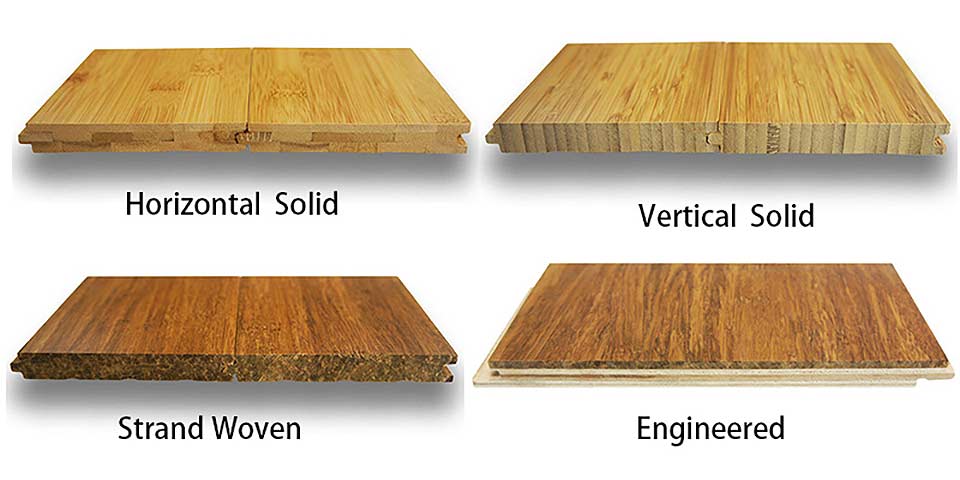

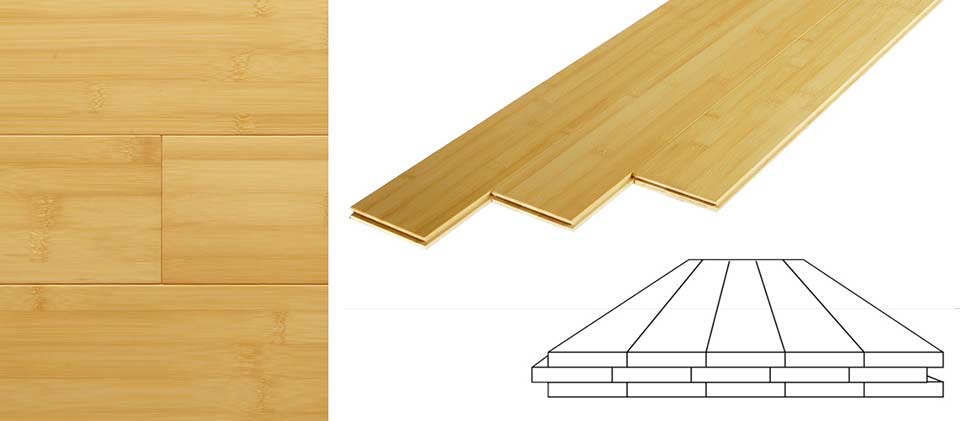

Structure

Natural Bamboo Flooring

Carbonized Bamboo Flooring

Natural Carbonized Bamboo Floor

Bamboo Flooring Advantage

Details Images

Bamboo Flooring Technical Data

| 1) Materials: | 100% Raw Bamboo |

| 2) Colors: | Strand Woven |

| 3) Size: | 1840*126*14mm / 960*96*15mm |

| 4) Moisture content: | 8%-12% |

| 5) Formaldehyde emission: | Up to E1 standard of Europe |

| 6) Varnish: | Treffert |

| 7) Glue: | Dynea |

| 8) Glossiness: | Matt, Semi gloss |

| 9) Joint: | Tongue & Groove (T& G) click ; Unilin+Drop click |

| 10) Supply ability: | 110,000m2 / month |

| 11) Certificate: | CE Certification , ISO 9001:2008, ISO 14001:2004 |

| 12) Packing: | Plastic films with carton box |

| 13) Delivery Time: | Within 25 days after received advance payment |

Click System Available

A: T&G Click

T&G LOCK BAMBOO-Bamboo Florinig

Bamboo T&G -Bamboo Florinig

B: Drop (short side)+ Unilin click (length side)

drop Bamboo Florinig

unilin Bamboo Florinig

Bamboo flooring package list

| Type | Size | Package | NO Pallet/20FCL | Pallet/20FCL | Size of Box | G.W. | N.W. |

| Carbonized Bamboo | 1020*130*15mm | 20pcs/ctn | 660 ctns/1750.32 sqm | 10 plt, 52ctns/plt,520ctns/1379.04 sqms | 1040*280*165 | 28kgs | 27kgs |

| 1020*130*17mm | 18pcs/ctn | 640 ctns/1575.29 sqm | 10 plt, 52ctns/plt,520ctns/1241.14 sqms | 1040*280*165 | 28kgs | 27kgs | |

| 960*96*15mm | 27pcs/ctn | 710 ctns/ 1766.71 sqm | 9 plt, 56ctns/plt,504ctns/1254.10 sqms | 980*305*145 | 26kgs | 25kgs | |

| 960*96*10mm | 39pcs/ctn | 710 ctns/ 2551.91 sqm | 9 plt, 56ctns/plt,504ctns/1810.57 sqms | 980*305*145 | 25kgs | 24kgs | |

| Strand Woven Bamboo | 1850*125*14mm | 8pcs/ctn | 672 ctn, 1243.2sqm | 970*285*175 | 29 kg | 28 kg | |

| 960*96*15mm | 24pcs/ctn | 560 ctn, 1238.63sqm | 980*305*145 | 26 kg | 25 kg | ||

| 950*136*17mm | 18pcs/ctn | 672ctn, 1562.80sqm | 970*285*175 | 29 kg | 28kg |

Packaging

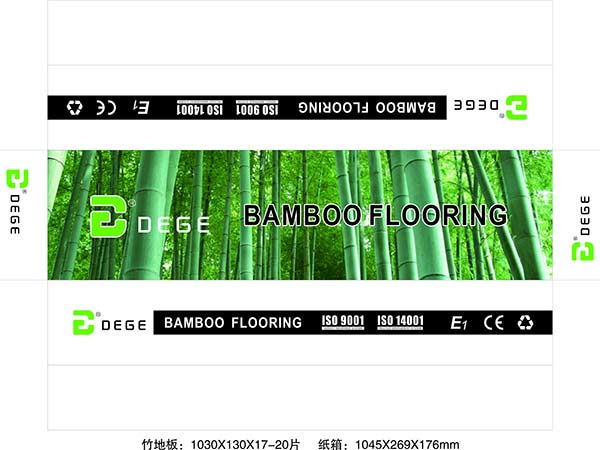

Dege Brand Packaging

General Packaging

Transportation

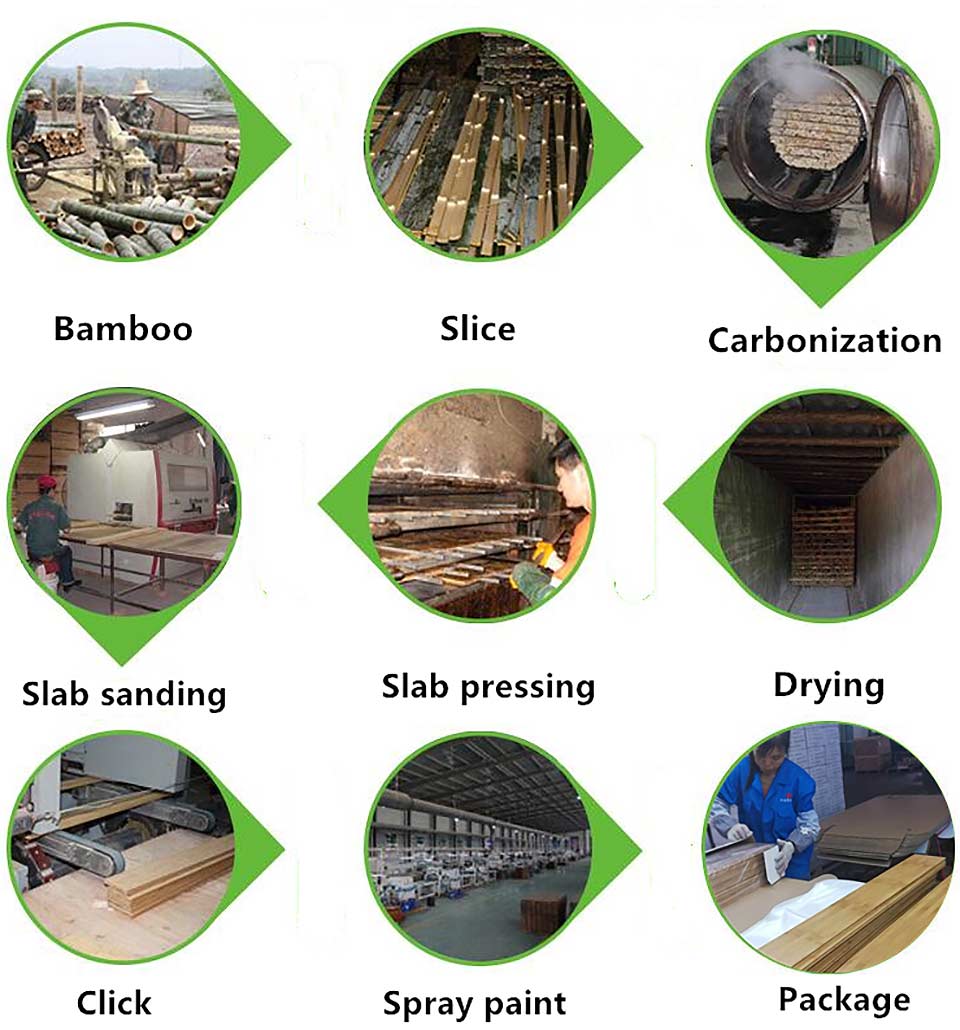

Product Process

Applications

How is bamboo floor installed (detailed version)

How is bamboo floor installed (detailed version)

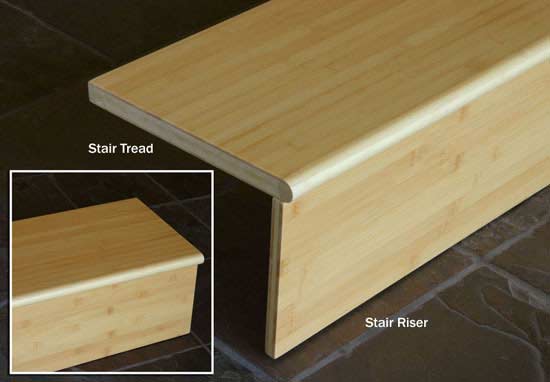

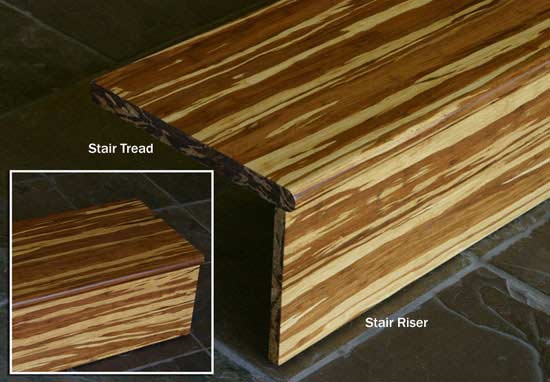

Stair slab

Stair slab

| Characteristic | Value | Test |

| Density: | +/- 1030 kg/m3 | EN 14342:2005 + A1:2008 |

| Brinell hardness: | 9.5 kg/mm² | EN-1534:2010 |

| Moisture content: | 8.3 % at 23°C and 50% relative humidity | EN-1534:2010 |

| Emission class: | Class E1 (LT 0,124 mg/m3, EN 717-1) | EN 717-1 |

| Differential swelling: | 0.17% pro 1% change in moisture content | EN 14341:2005 |

| Abrasion resistance: | 16’000 turns | EN-14354 (12/16) |

| Compressability: | 2930 kN/cm2 | EN-ISO 2409 |

| Impact resistance: | 6 mm | EN-14354 |

| Fire properties: | Class Cfl-s1 (EN 13501-1) | EN 13501-1 |