What is Multilayer Engineered Flooring?

1.Structure:

1.1.The Engineered Flooring first layer is usually with UV coating of natural oil.

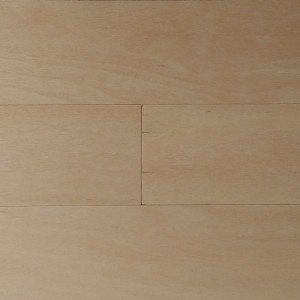

1.2.The second layer is the hardwood top layer and it is also called veneer layer and it can be oak, walnut, maple, birch, etc. And the veneer thickness is usually 2mm, 3mm, 4mm, etc.

1.3.The third layer is the plywood core layer and this layer uses different species of veneers forming plywood, such eucalyptus, poplar, birch.

1.4.The fourth layer is the backing layer and it is to provide stability to the board and its species is usually poplar.

2.Specifications

| Flooring Type | Prefinished | Species | Maple/Hard Maple |

| Color | Brown | Shade | Medium/Neutral Shade |

| Finish Type | Urethane | Gloss Level | Low-Gloss |

| Application | Residential | Core Type | Multi-Ply |

| Profile | Tongue & Groove | Edge Type | French Bleed |

| Maximum Length (in.) | 48 | Minimum Length (in.) | 20 |

| Average length (in.) | 33 | Width (in.) | 5 |

| Thickness (in.) | 0.55 | Radiant Heat Compatible | No |

| Below Grade | Yes | Installation | Floating, Glue Down, Nail Down, Staple Down |

| Certification | CARB II | Wear Layer Thickness (mm) | 3 |

| Surface Finish | Distressed, Handscraped | Finish Warranty (in years) | 25 years |

| Structural Warranty (in years) | 25 Years | Country of Origin | China |

| Packaging Dimensions (inches) | Height: 4.75 Length: 84 Width: 5 | Product Dimensions | Height: 9/16" Length: 15 3/4 - 47 1/4" Width: 5" |

| Sqft / Box | 17.5 | Proposition 65 | Attention California Residents |

3 Layer Engineered Structure

Multilayer Engineered Structure

Engineered Flooring Advantage

Specifications

| Wood Flooring species: | Oak, Maple, Birch, Cherry ,Teak, Ash, Rosewood, Walnut, etc. | |

| Origin: | Europe, America, China | |

| Dimensions: | Length: From 300mm to 2200mm | |

| Width: From 60mm to 600mm | ||

| Thickness: From 7mm to 22mm | ||

| Structure: | Multilayer or 3 Layers | |

| Top layer: | 0.2mm/0.6mm/2mm/3mm/4mm/5mm/6mm | |

| Veneer Grade: | AB/ABC/ABCD | |

| Moisture content | 8% +/-2 | |

| Joint system | T&G | |

| Core material: | Eucalyptus , Poplar ,Birch | |

| Glue: | Dynea Phenolic aldehyde resin (CARB P2, E0) | |

| Color: | Medium, Light, Natural, Dark | |

| Surface treatments: | Smooth/wire-brushed/hand-scraped/distressed/carbonized/smoked | |

| Finish: | Treffert UV coating, OSMO natural oil | |

| Installation: | Glue, float or nail down | |

| Package: | Cartons or Pallet | |

| Certificate: | CE,SGS,FSC,PEFC, ISO9001,ISO140001 | |

| OEM: | Offered | |

What is engineered wood flooring advantage than hardwood flooring ?

Multi-layer solid wood flooring is a new type of flooring between solid wood flooring and laminate flooring, and is a new trend in floor purchase. Multi-layer solid wood flooring retains all the advantages of natural solid wood flooring. It not only has the natural texture and elasticity of solid wood flooring, but also overcomes the common problems of natural solid wood flooring that is easy to swell and shrink. It has the characteristics of anti-deformation, corrosion resistance and easy cleaning.

The multi-layer solid wood floor is a plywood structure. Its surface layer is made of precious wood by rotary cutting into thin wood. The substrate under the surface layer is made by cutting ordinary wood into thin slices, making it crisscross, multi-layer combination, and then using environmentally friendly waterproof adhesive. The multi-layer sheet is compounded by high temperature and high pressure, and the wood fibers are arranged in a net-like superimposed manner. The structure is very tight and the performance is specific and stable. It completely overcomes the shortcomings of natural materials that are easy to deform.

The surface layer of the multi-layer solid wood floor is coated with paint several times, so that the paint penetrates into the voids of the wood structure, and infrared radiation, electronic rays and thermal radiation are added to form a whole in the wood structure, so that the wood is hardened. Therefore, the multi-layer solid wood floor is not easy to be polluted, not easy to be scratched, has strong wear resistance, and can maintain the beauty of new materials and the texture of solid wood for a long time.

Due to the multi-layer glue compound, the multi-layer solid wood floor has good waterproof performance and can be used in wetter floors and areas. Multi-layer solid wood flooring has been treated with insect-proof treatment, and environmentally-friendly glue is used, which can effectively prevent insect damage and is non-toxic to humans.

Practice has proved that the foot comfort of multi-layer solid wood flooring is the same as that of natural solid wood flooring, and the paving method is basically the same. Due to obvious advantages, its market usage is gradually increasing.

When choosing a multi-layer solid wood floor, you must first choose the appearance quality. It depends not only on whether the color, texture and paint quality of the surface wood meets the grade standard, but also whether there is decay, dead knots, knot holes, worm holes, sandwich resin capsules, Wood defects such as cracks or loose joints, the wood texture and color perception are harmonious, the paint should be uniform, no bubbles, small white spots, etc., and the surface should not be damaged by obvious stains. While choosing the appearance, you should also observe whether the tongue and groove around the floor are complete.

Secondly, choose whether the size of the product is consistent with the length, width, and thickness of the size you purchased, and then check whether the dimensional tolerance of the product is consistent with the purchased grade. The measurement method can take multiple pieces of floor in the same packing box and assemble it by yourself. After assembling, observe whether the tenon and groove are tightly combined. At the same time, you can touch the floor after splicing to see if it is irregular. If there is a prominent hand feeling phenomenon , Indicating that the product is unqualified. After touching it by hand, pick up two assembled multi-layer solid wood floors and shake them in your hands to see if they are loose.

Finally, select the intrinsic quality, which is a key indicator of multilayer solid wood flooring. It can be seen from the water absorption thickness expansion rate that its waterproof and moisture-proof performance, the lower the better, the best is less than 2%, followed by less than 5%. Pyrotechnics are burned on the surface. If there are no traces, the fireproof coefficient is higher. The formaldehyde content is an index that cannot be ignored. According to national regulations, the formaldehyde content per 100g floor shall not exceed 9mg. "Three-point floor and seven-point installation", so it is recommended to choose DEGE brand flooring when choosing multilayer solid wood flooring

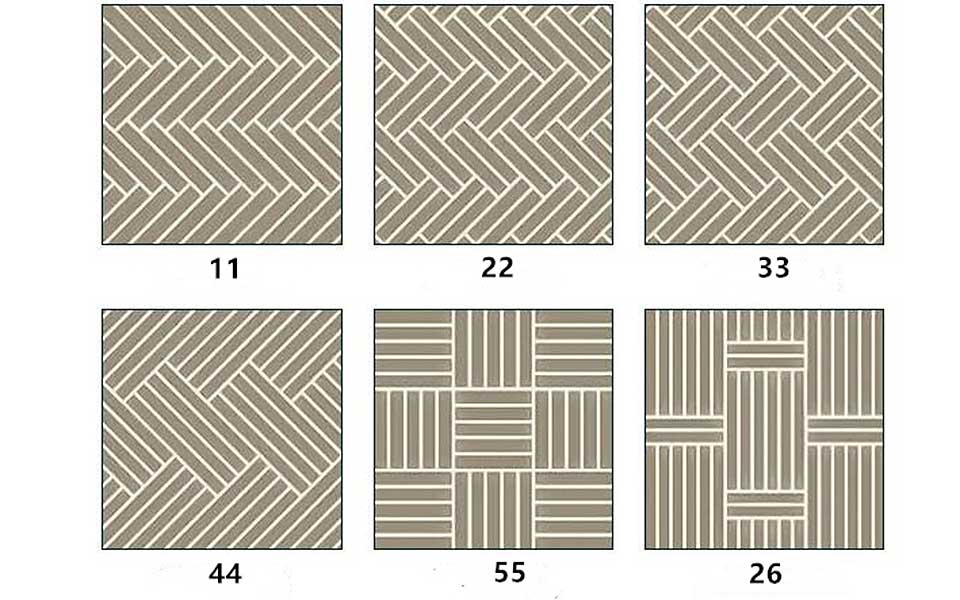

Design Type

Click Type

T&G Engineered Flooring

Unilin Engineered Flooring

Finish Type

Hand-scraped Brushed Engineered Flooring

Light Wire-Brushed Engineered Flooring

Smooth Surface Engineered Flooring

Veneer Grade

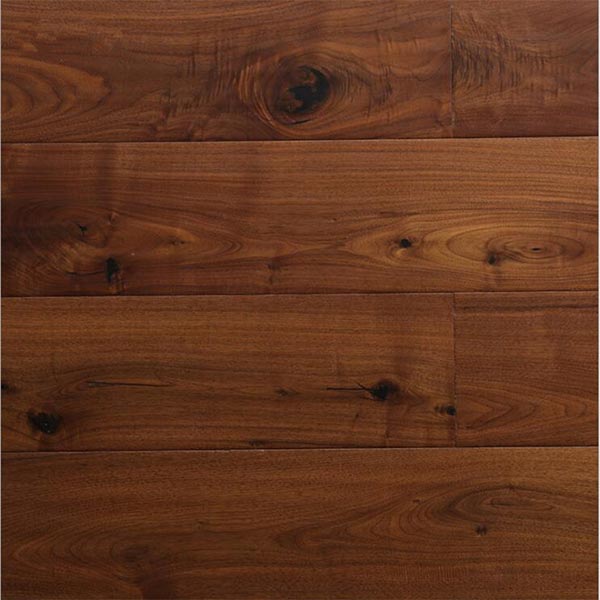

ABCD engineered flooring

CDE engineered flooring

ABC engineered flooring

AB engineered flooring

How to Distinguish Engineered Flooring Veneer Grade

1. Distinguish Method

Grade A: knots are not allowed;

Grade B:Quantity of knots per pc: 1-3pcs and the diameter of knots whose color are black is within 8mm and diameter of knots whose color are nearly same as veneer is within 10mm;

Grade C: Quantity of knots per pc: 1-3pcs and the diameter of knots whose color are black is within 20mm and diameter of knots whose color are nearly same as veneer is within 25mm; In addition, 20% of white edge of plank width is allowed and medium color variation is allowed;

Grade D: Quantity of knots per pc: 1-3pcs and the diameter of knots whose color are black is within 30mm and diameter of knots whose color are nearly same as veneer is unlimited; In addition, length of crack is within 30cm and severe color variation is allowed;

2.Percentage

ABC Grade: Percentage of grade AB: 15%, Percentage of grade C: 85%;

ABCD Grade: Percentage of grade AB: 20%, Percentage of grade C: 50%, Percentage of grade D: 30%

3.Picture

Certificate

Product Process

Our Market

Applications

Project 1

Project 2

How to Install Engineered Wooden Flooring

How to Install Engineered Wooden Flooring

STEP 1.

Clean the ground, shovel the cement protruding from the ground, and then use a broom to clean it up. The sand and cement slurry on the ground must be thoroughly cleaned, otherwise it will rustle after installation!

Remarks:

The floor can be laid only when the moisture content of the ground is less than 20, otherwise, the floor will become moldy and arched after laying it!

STEP 2.

After all the ground is cleaned, spread a thin layer of plastic film, which should be completely covered, and the joints should be connected to separate the floor and the ground.

STEP 3.

After laying out the plastic film, lay the special mulch film on the floor. It should also be leveled and laid solid. It is best to have two people help.

STEP 4.

After laying the mulch, the installer took out a lot of floors from the box and spread them all on the ground, choosing the color difference, placing the big color difference under the bed and closet, and spreading it on the obvious place with uniform color difference.

STEP 5.

Start the formal installation of the floor. The installation master cuts the floors one by one, and then installs them as shown in the following figure. Just use a hammer to tighten between the floor and the floor. The installation master is very skilled and the installation speed is very fast! Leave a distance of about 1 cm between the floor and the wall.

STEP 6.

If the floor is too long, put it on the floor cutter and cut it to the required length. The cutting machine cannot be placed directly on the floor tiles. In order to prevent the pit from being smashed out, a thick cardboard should be placed on the floor.

STEP 7.

Generally, the installation of the floor is carried out by 2 people, a total of about 35 square meters, and it only took 6 hours in total.

STEP 8.

After the floor is installed, place a spring between the floor and the wall. The spring will expand and contract with heat. Use a special iron tool to insert it into the gap.

STEP 9.

To install the skirting, you need to fix the skirting on the wall with nails, and seal the skirting and the wall with glass glue.

STEP 10.

The floor and skirting are all installed, their colors are still quite matching, and the newly installed floor is also very beautiful, so the installed floor has no sound.

Different Engineering Wooden Flooring, Installation Methods

Different Engineering Wooden Flooring, Installation Methods

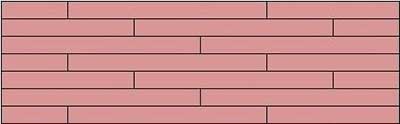

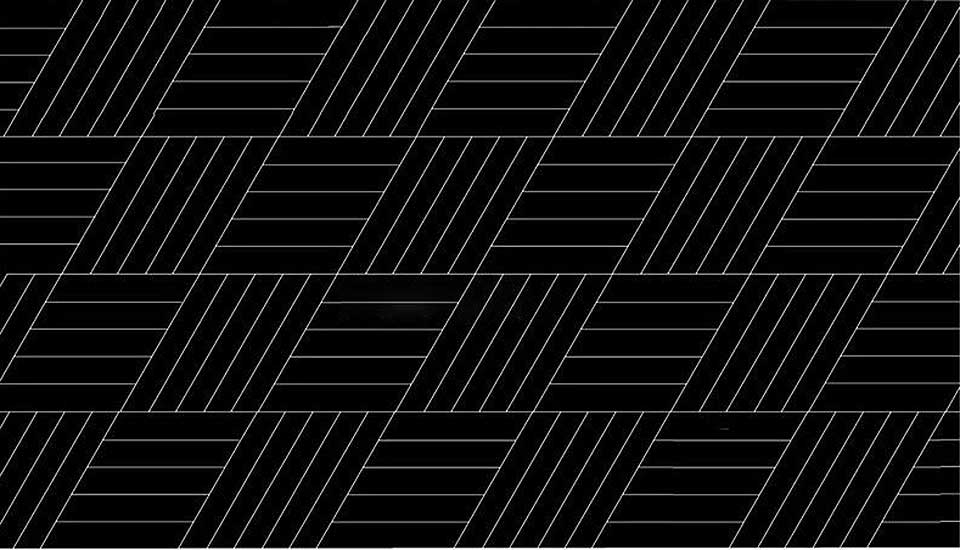

1.Classic Series Engineered Flooring

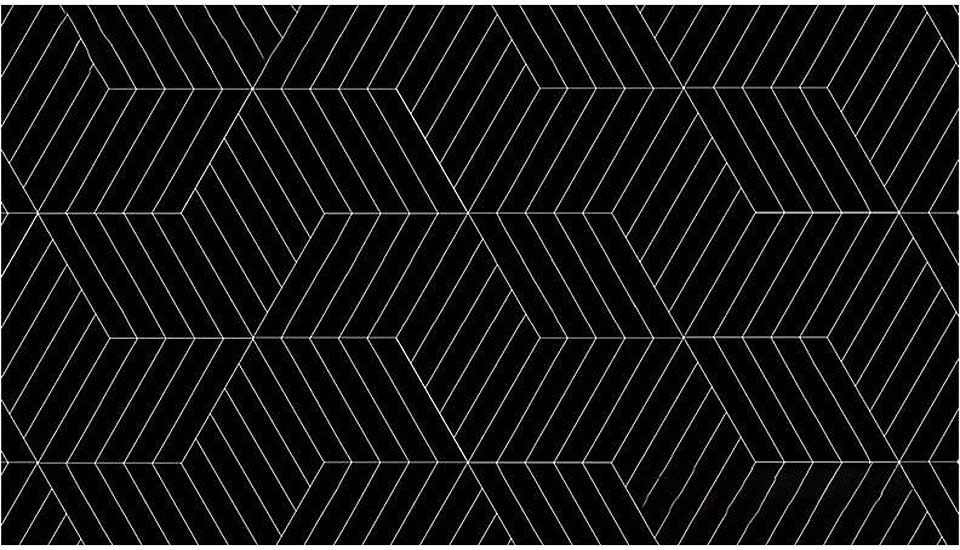

2.Herringbone Series Engineered Flooring

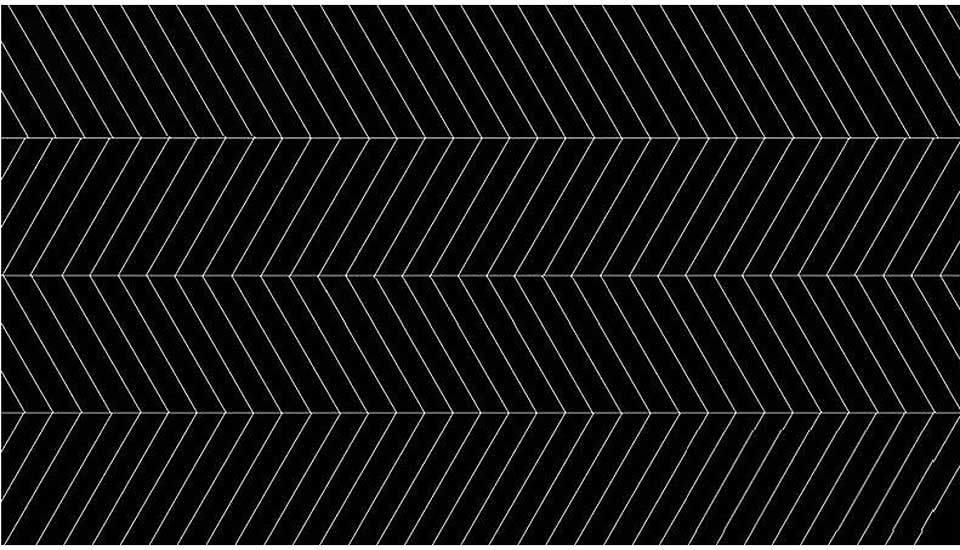

3.Chevron Series Engineered Flooring

| Fire Protection: | Reaction to fire – wood flooring performs to EN 13501-1 Dn s1 |

| Thermal Conductivity: | EN ISO 10456 and EN ISO 12664 Result 0.15 W/(mk) |

| Moisture Content: | EN 13183 – 1 Requirement: 6% to 9% Average Results: <7% |

| Thermal Conductivity: | EN ISO 10456 / EN ISO 12664 Result 0.15 W / (mk) |

| Release of Formaldehyde: | Class E1 | EN 717 – 1:2006 Result 0.014 mg / m3 Requirement: Less than 3 ppm Result: 0.0053 ppm |

| Slip Resistance: | Tested to BS 7967-2: 2002 (Pendulum Test in PTV values) Oiled Finish results: DRY (66) LOW RISK WET (29) MODERATE RISK There is no current requirement for slip resistance in residential developments. |

| Suitability of use: | Suitable for use with under floor heating in commercial and residential applications |

| Effects from moisture: | Wood flooring will expand if it is exposed to conditions that increases its moisture content beyond 9%. Wood flooring will contract if the prevailing conditions reduce the product moisture content below 6%. Any exposure outside of these parameters will compromise the performance of the product |

| Transmission of Sound: | Wood flooring on its own will offer some assistance to reduce the passage of sound, but it is the build-up of the whole floor and the surroundings that contribute to impact and airborne sound. For accurate assessment’s a qualified engineer should be employed to calculate how to achieve accurate results. |

| Thermal properties: | Solid Wood Flooring boards offer the following values: 20mm thick boards with a 4mm or 6mm top layer will lose 0.10 K/Wm2 15mm boards with a 4mm or 6mm top layer will lose 0.08 K/Wm2 |