What is Artificial Grass?

Artificial grass can be divided into 2 main kinds according to the production process: injection-molded artificial grass and woven artificial grass. Its raw material are mostly polyethylene(PE) and polypropylene(PP). But sometimes it also use polyvinyl chloride and polyamide.

PE material is very soft and looks like real grass. So it is widely accepted by customers. It is the most common material used for artificial grass.

PP material is more rigid and often used for tennis court, playground and any other sports area. The wear resistance is slightly worse than PE.

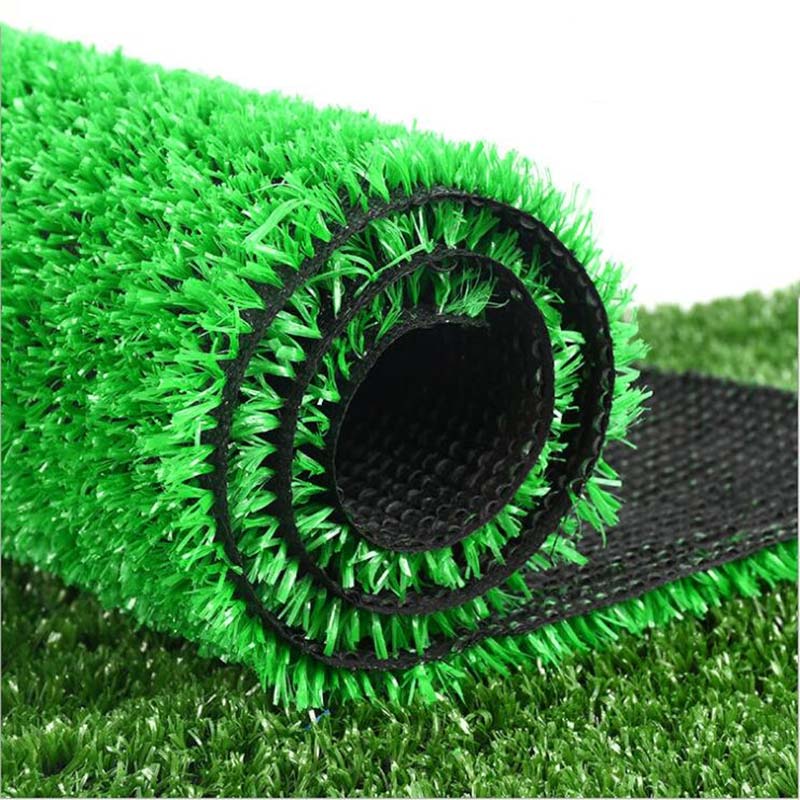

The structure of artificial grass is usually 3 layers.

First layer: Basement. It is composed of rammed soil, gravel and asphalt or concrete.

Second layer: Buffer Layer. It is composed of rubber or foam. Rubber has moderate elasticity and the thickness is around 3-5mm. The cost of using foam is less, but the elasticity is poor. Its thickness is around 5-10mm. It should achieve a balance of the thickness.

Third layer is also the surface layer or called turf layer. According to the surface shape, there are pile turf, circular crimped nylon silk turf, leaf-shaped polypropylene fiber turf, nylon silk woven permeable turf, etc.

Artificial grass was born in the United States in the 1960s. It is made by manual methods to use the vinyl chemical fiber as raw material. Unlike the natural grass, fertilizer and water are not necessary for artificial grass. It can be used for 24 hours all day especially for sporting. It is widely used in hockey, baseball, rugby and many other sports public practice fields or just as a ground paving to beautify the indoor environment.

Together with the plastic track, it has become the standard mode of school sports construction, replacing the natural turf. Although the application range of artificial turf has been limited to some extent due to reasons such as sports safety, site characteristics and public awareness. But it has been continuously innovated and improved.

Structure

Artificial Turf Constrution

Size

Artificial Grass Advantage

Football Artificial Grass Specifications

| Item | Leisure Grass |

| Color | PGL01 |

| Yarn Type | PE+PP/PP |

| Pile height | 6mm-15mm |

| Stitch rate | 200stiches/m-300stiches/m |

| Gauge | 3/16 inch |

| Dtex | 8800, 9500// 1800 |

| Backing | PP+SBR, PP+Fleece+SBR |

| Roll length | 25m or customized |

| Roll width | 2m, 4m |

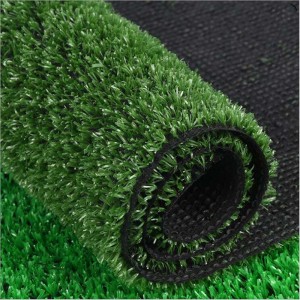

| Package | Wrapped on 10cm diameter paper pipe, covered by PP cloth |

| Infill Requirements | NO |

| Application | landscaping, leisure usage, kindergarten |

| Warranty | 8-10years |

| Delivery time | 7-15days |

| Certificates | ISO9001/ ISO14001/ CE/ SGS, etc. |

| Loading Quantity | 20' GP: about 3000-4000sqm; 40HQ:about 8000-9000qm |

Details Images

Back Design Type

Quality Inspection

Super waterproof permeable

High density and more durable

Natural and environmental friendly

Super flame retardant

Artificial Grass Production Process

1 artificial grass Yarn Making

4 Turf Weaving

7 Finished Turf

2 Finished Yarn

5 Semi-finished Turf

8 artificial turf Package

3 Turf Rack 2

6 Backing Coating and Drying

9 artificial grass Warehouse

Package

Artificial Grass Bag Package

Artificial Turf Box Package

Artificial Turf Loading

Applications

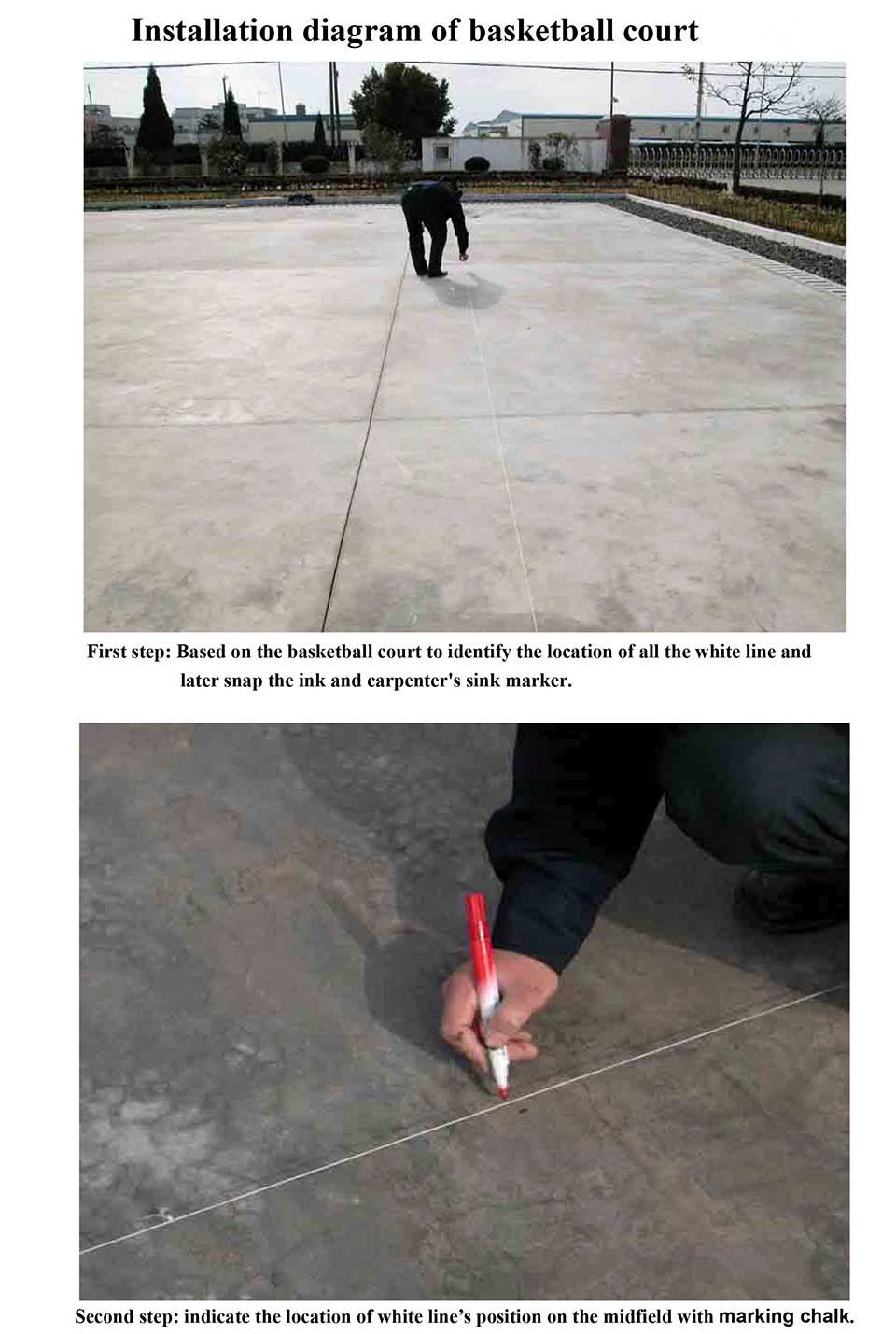

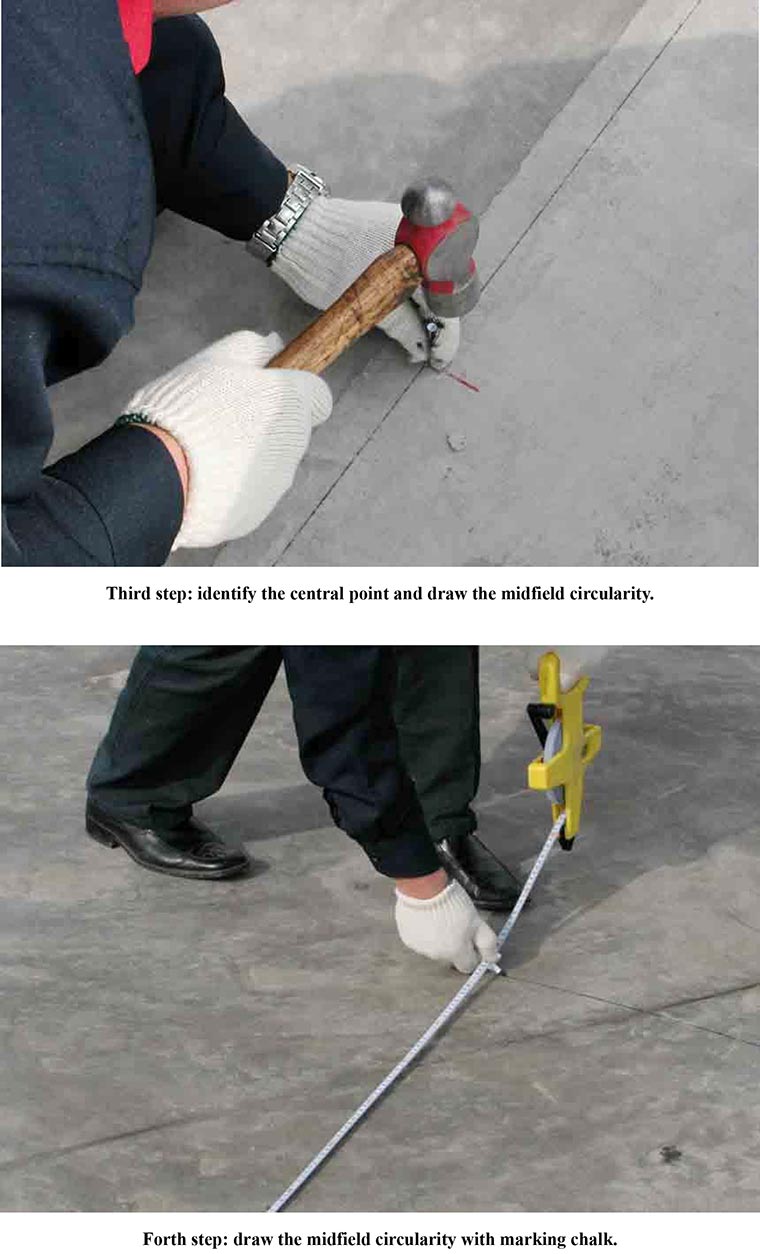

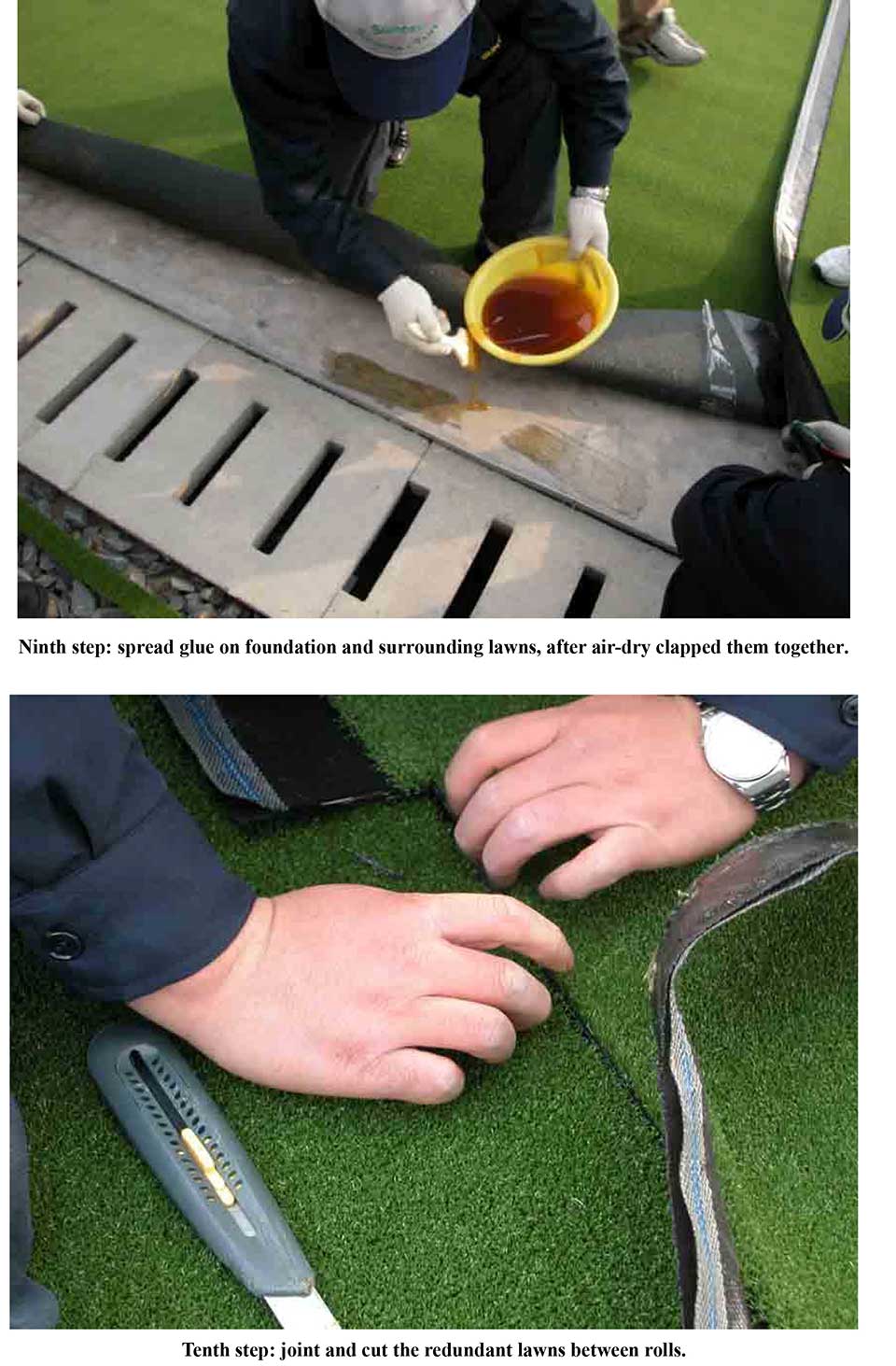

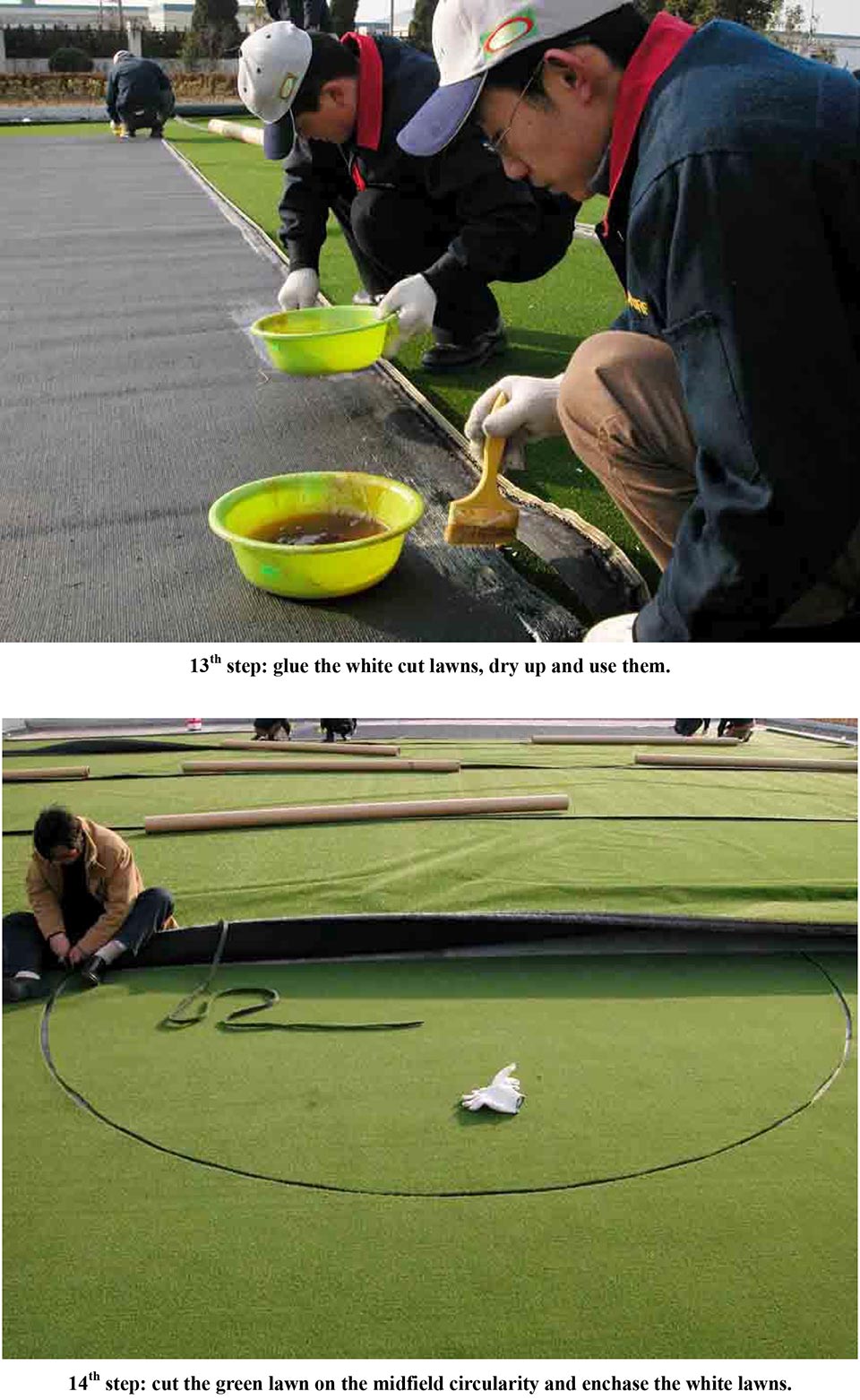

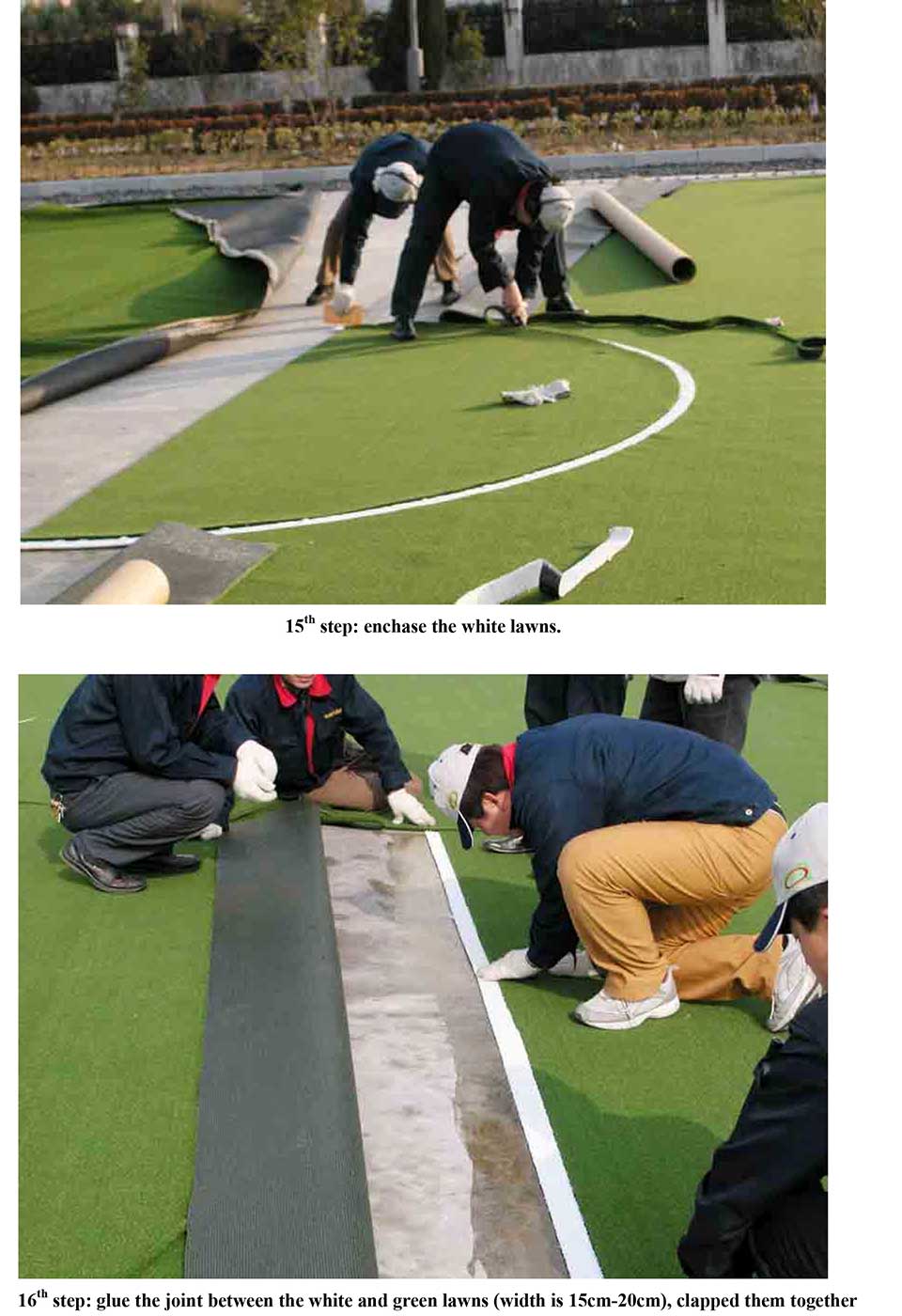

Installation Steps

Installation Steps

Installation Tools

Installation Tools

| Characteristic | Value | Test |

| Synthetic Grass for Landscaping | ||

| Standard Roll Width: | 4m / 2m | ASTM D 5821 |

| Standard Roll Length: | 25m / 10m | ASTM D 5822 |

| Linear Density (Denier) | 10,800 Combined | ASTM D 1577 |

| Yarn Thickness | 310 Microns (mono) | ASTM D 3218 |

| Tensile Strength | 135 N (mono) | ASTM D 2256 |

| Pile Weight* | 10mm-55mm | ASTM D 5848 |

| Gauge | 3/8 inch | ASTM D 5826 |

| Stitch | 16 s / 10cm (± 1) | ASTM D 5827 |

| Density | 16,800 S/Sq.m | ASTM D 5828 |

| Fire Resistance | Efl | ISO 4892‐3:2013 |

| UV STABILITY: | Cycle 1 (Grey Scale 4‐5) | ISO 105‐A02:1993 |

| Fiber manufacturer must be from the same source | ||

| The above specifications are nominal. *Values are +/- 5%. | ||

| Finished Pile Height* | 2″ (50mm) | ASTM D 5823 |

| Product Weight (total)* | 69 oz./yd2 | ASTM D 3218 |

| Primary Backing Weight* | 7.4 oz./yd2 | ASTM D 2256 |

| Secondary coating Weight** | 22 oz./yd2 | ASTM D 5848 |

| Fabric Width | 15′ (4.57m) | ASTM D 5793 |

| Tuft Gauge | 1/2″ | ASTM D 5793 |

| Grab Tear Strength | 200-1b-F | ASTM D 5034 |

| Tuft Bind | >10-1b-F | ASTM D 1335 |

| Infill (Sand) | 3.6 lb Silica Sand | None |

| Infill (Rubber) | 2 lbs. SBR Rubber | None |

| Underlayment Pad | Trocellen Progame 5010XC | |

| Except where noted as a minimum, the above specifications are nominal. | ||

| * Values are +/- 5%. **All values are +/- 3 oz./yd2. | ||