Structure

Specifications

| Specification | |||

| Model Material | WPC | ||

| Model Name | WPC SKIRTING, WPC REDUCER,WPC TMOLDING, WPC CONCAVE LINE and SCOTIA,WPC L END CAPE, WPC FLUSH STAIR NOSE | ||

| Size | T-MOLDING:2400*38*7MM

REDUCER:2400*43*10MM END CAP:2400*35*10MM QUARTER ROUND:2400*28*16MM STAIR NOSE:2400*54*18MM FLUSH STAIR NOSE :2400*72*25MM FLUSH STAIR NOSE :2400*110*25MM |

||

| MOQ | 100PCS | ||

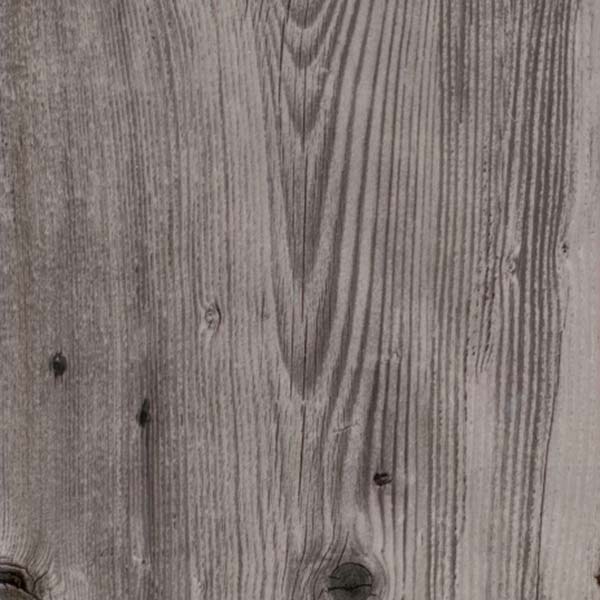

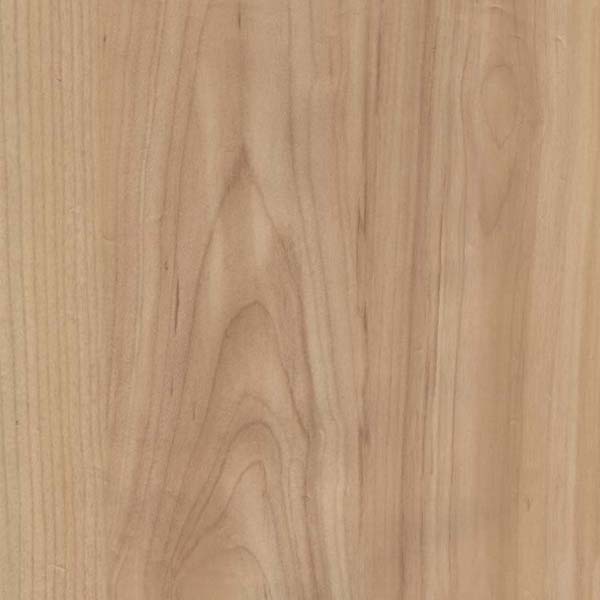

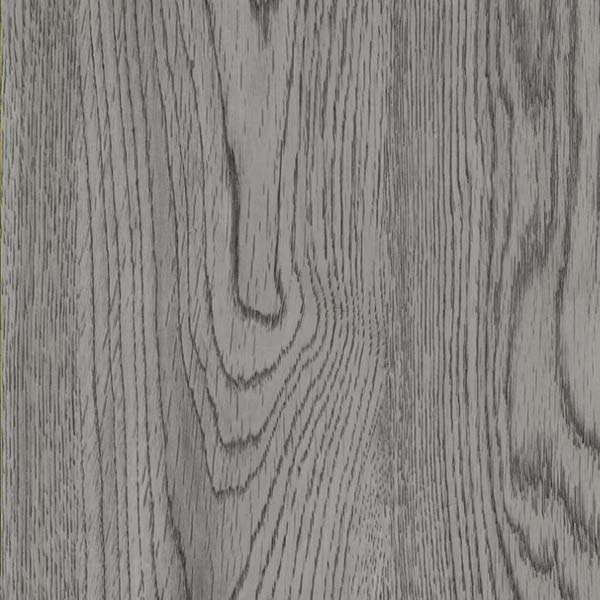

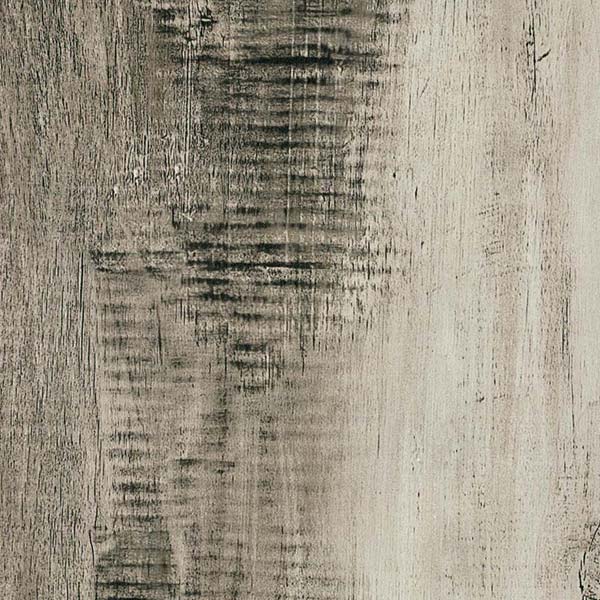

| Color | OAK, CHERRY, WALNUT, ASH, BEECH, PINE, Blackbutt, Spotted Gumm | ||

| Package | Inner packing: plastic bag. | ||

| Outer packing: pallets are covered with plywood or carton and then steel for strength | |||

| or customized | |||

| Delivery Time | 20 days | ||

| Certificate | CESGSISO9001 | ||

| Application | laminate flooring, pvc flooring, spc vinyl flooring, wooden flooring etc | ||

| Feature | Waterproof, Fireproof, Soundproof, Wear Resistence | ||

Actual Picture of Stair Board

Big Wpc Stair Moulding

| Materials | WPC |

| Colors | OAK, WALNUT,CHERRY,MAPLE, TEAK, ASH and so on. |

| Product Thickness | <=6MM (0.24in.) or >6MM(0.24in.) |

| Rroduct Size | 2200X300X24MM (86.6*11.81*0.94in.) |

| Carton Size | 2220x155x95MM (87.4*6.1*3.74in.) |

| Carton Packing | 10PCS/CTN; 8200PCS/20GP |

| Pallet Packing | 5280PCS/20GP |

| Weight/Caton | 50KGS (110.2lbs) |

| Place Of Origin | China |

| Specification | Our standard size or Customized size |

| Profile | Our standard profile or customized profile |

| MOQ | 150-200 PCS single color,700-800 PCS multi-color |

| Package | pallets are covered with plywood, carton and stretch film |

| Port | Shanghai |

| Delivery time | <=1000pcs 5-7 days,1000-5000pcs 10-15Days |

| Feature | Surface Water-Proof, Anti-Scratch, etc |

| Relative products | Skirting, baseboard, Reducer, End moulding, stair nosing, quarter round molding etc. |

| Application | laminate flooring, pvc flooring, spc vinyl flooring, wooden flooring etc |

Application of Stair Board

Package and Loading

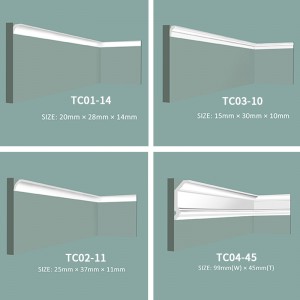

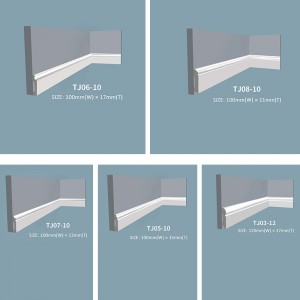

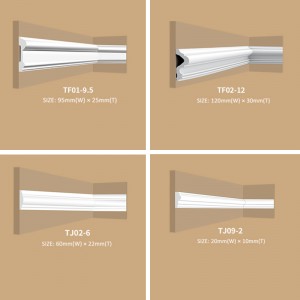

FLUSH-STAIR-wpc-NOSE

FLUSH-STAIR-wpc-NOSE  shaoe

shaoe  wpc-END-CAP

wpc-END-CAP  wpc-QUARTER-ROUND

wpc-QUARTER-ROUND  wpc-REDUCER

wpc-REDUCER  wpc-SCOTIA

wpc-SCOTIA  wpc-SKIRTING

wpc-SKIRTING  wpc-T-MOULDING

wpc-T-MOULDING wpc-OVERLAP-STAIR-NOSE

wpc-OVERLAP-STAIR-NOSE

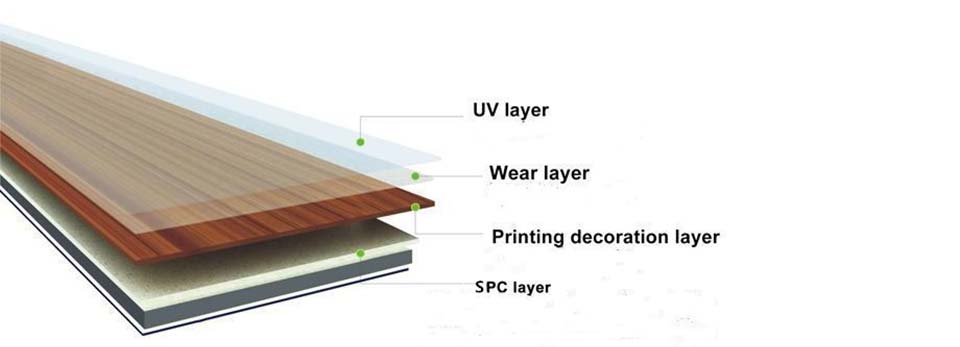

What is WPC FLUSH STAIR NOSE ?

What is WPC FLUSH STAIR NOSE ?

It is one kinds new material for done FLUSH STAIR NOSE. The structure is wpc color + decorative paper film.WPC, called Wood Plastic Composite, is a kind of composite material made by adding a smallamount of chemical additives and fillers to plastics and wood fibers and processing by special mixing equipment. WPC has high environmental protection, pollution-free, recyclable use. Greatly reduces the use of wood, and the characteristic of waterproof and moisture-proof can make WPC used in environment which traditional wood products can not be used to.

About the decorative paper film is produced by through printing, so it can be done same with your flooring .Now DEGE Brand can supply the oak, beech ,walnut ,cherry, teak,ash ,birch color for stairnose.

WPC FLUSH STAIR NOSE VS MDF STAIR NOSE

WPC FLUSH STAIR NOSE VS MDF STAIR NOSE

1). 100% waterproof and so it can be used in wet areas;

2). Environment-friendly, Formaldehyde less, Odorless;

3).Super wear resistance: WPC FLUSH STAIR NOSE surface has a special transparent wear layer with high technology and it is the best among all of flooring accessories . wpc accessories becomes more and more popular.

4). Durable, acid and alkali resistant, antifungal, anti-static;

5). Fireproof and Flame-retardant: Its flammability and smoke density reach national B1 standard and it is with super flame resistance, increasing the safety factor of human living;

6). Super anti-slip: WPC Stair nose Wear Layer has the special slip resistance;

7). Sound-absorbing and anti-noise: Wpc Accessories has good sound absorbing function that the other floors can not be compared and its sound absorption is up to 20 decibels. And so the places requiring quiet environment such as hospital wards, libraries, lecture halls, theaters choose it.

8). Quick and Easy Installation: It is very easy and fast to install wpc accessories and without cement mortar and if the ground is flat, it can be installed directly and can be used after 24 hours.

9). It is more stable than mdf FLUSH STAIR NOSE and its expansion rate is about 0.2%.

| No | Characteristic | Technology Target | Remark | |||||

| 1 | Appearance | No chipping, cracking, visual texture, delamination, bubbles, shallow embossing, scratches, dirt, poor cut, etc | ENEN649 | |||||

| 2 | Size mm (23℃) | Length | ± 0.20mm | EN427 | ||||

| Wide | ± 0.10mm | EN427 | ||||||

| Thickness | +0.13mm, -0.10mm | EN428 | ||||||

| Thickness Range | ≤0.15 mm | EN428 | ||||||

| wearlay Thickness | ± 0.02 mm | EN429 | ||||||

| 3 | Squareness mm | ≤ 0.15 | EN427 | |||||

| 4 | Crook mm | ≤ 0.15 | EN427 | |||||

| 5 | Microbevel Cut Angle | 8-15 degrees | ||||||

| Microbevel Cut Depth | 0.60 – 1.5 mm | |||||||

| 6 | Dimensional stability after exposure to heat | ≤ 0.12% | EN434 | |||||

| 7 | Curling after exposure to heat | WPC:≤0.2(70℃/6Hr) | EN434 | |||||

| SPC:≤0.2(80℃/6Hr) | ||||||||

| 8 | Gloss level | nominal value ± 1.5 | Lightmeter | |||||

| 9 | Taber Abrasion - Minimum | 0.5mm wear lay | ≥5000 cycles Average | EN660 | ||||

| 10 | Uv | 8~12g/m2 | ||||||

| 11 | ≥9N | |||||||

| SCRATCH PERFORMANCE UV | SCLEROMETER | |||||||

| 12 | Anti-stain performance | Iodine | 3 | Modified ASTM 92 | ||||

| Oil Brown | 0 | |||||||

| Mustard | 0 | |||||||

| Shope Polish | 2 | |||||||

| Blue Sharpie | 1 | |||||||

| 13 | Determination of flexibility | no crack | EN435 | |||||

| 14 | Peel Resistance | Length | ≥62.5N/5cm | EN431(62.5N/5cm,100mm/s) | ||||

| width | ≥62.5N/5cm | |||||||

| 15 | Residual indentation (average) mm | ≤0.15 | EN433 | |||||

| 16 | Color fastness: | ≥7 | ISO105-B2:2002 | |||||

| 17 | Locking Strength | fsmax ≥2 .5N/mm | ISO24344 | |||||